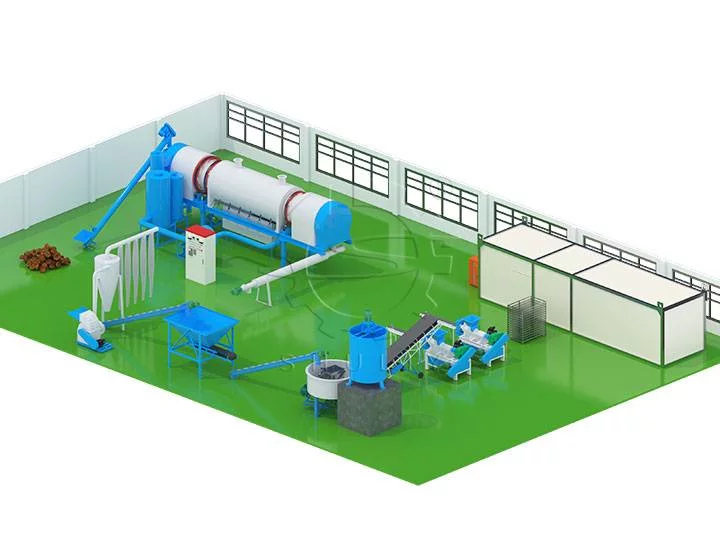

বারবিকিউ চারকোল উৎপাদন লাইনের সম্পূর্ণ নির্দেশিকা

আউটডোর বারবিকিউ সংস্কৃতির উত্থানের সাথে সাথে বারবিকিউ চারকোলের চাহিদা বাড়ছে। উচ্চ-মানের BBQ চারকোল কেবল দীর্ঘ সময় ধরে জ্বলে, ধোঁয়াহীন এবং পরিবেশ বান্ধব নয়, খাবারের জন্য একটি অনন্য চারকোল স্বাদও নিয়ে আসে।

তাহলে, এই উচ্চ-মানের BBQ চারকোল কিভাবে তৈরি হয়?

বারবিকিউ কয়লার উৎপাদন লাইনের বিস্তারিত

কাঁচামাল নির্বাচন এবং প্রাথমিক চিকিৎসা

বারবিকিউ চারকোলের বেশিরভাগ কাঁচামাল হল কৃষি ও বনজ বর্জ্য যেমন কাঠের গুঁড়ো, ধানের তুষ, বাঁশের shavings এবং নারকেলের খোসা। এই কাঁচামালগুলি পরবর্তী কার্বনাইজেশন প্রক্রিয়ায় প্রবেশের আগে স্ক্রীন এবং শুকানো হয়।

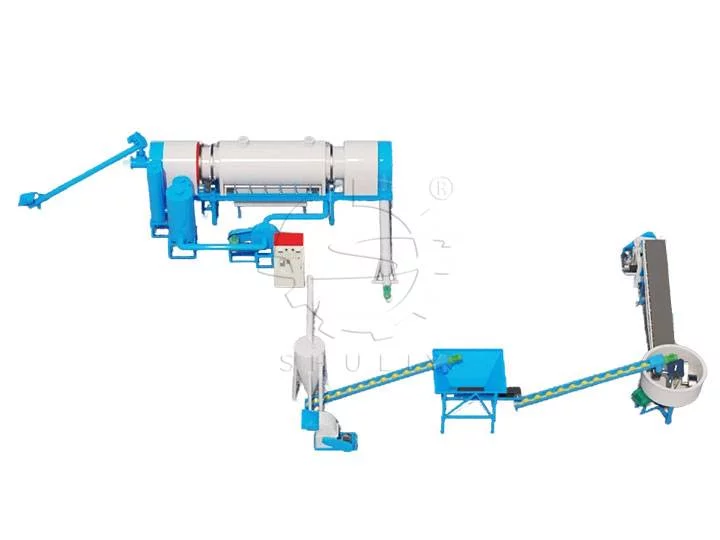

কার্বনাইজেশন ফার্নেস

বারবিকিউ চারকোল উৎপাদনে, চারকোল ফার্নেস হল মূল সরঞ্জামগুলির মধ্যে একটি। এই সরঞ্জামটি উচ্চ-তাপমাত্রার অ্যানেরোবিক বা মাইক্রো-অক্সিজেনিক পরিবেশে কাঁচামালকে কার্বনাইজ করে, কাঠের ফাইবারগুলি ধরে রাখে এবং চারকোলের বিশুদ্ধতা এবং ক্যালোরিফিক মান বাড়ানোর জন্য অপদ্রব্যগুলি সরিয়ে দেয়।

আমাদের অবিচ্ছিন্ন চারকোল ফার্নেস উচ্চ দক্ষতা এবং পরিবেশ সুরক্ষার সাথে উচ্চ-আয়তনের এবং অবিচ্ছিন্ন চারকোল উৎপাদন উপলব্ধি করতে পারে।

চারকোল গ্রাইন্ডিং মেশিন

কার্বনাইজেশনের পরে চারকোলকে পরবর্তী মিশ্রণ এবং ছাঁচনির্মাণের জন্য আরও গুঁড়ো করা প্রয়োজন। চারকোল গ্রাইন্ডিং মেশিন বড় চারকোলের টুকরোগুলিকে দ্রুত সূক্ষ্ম গুঁড়োতে পরিণত করতে পারে। অভিন্ন কণার আকার এবং স্থিতিশীল আউটপুট উচ্চ-ঘনত্বের চারকোল বল তৈরির জন্য গুরুত্বপূর্ণ পূর্বশর্ত।

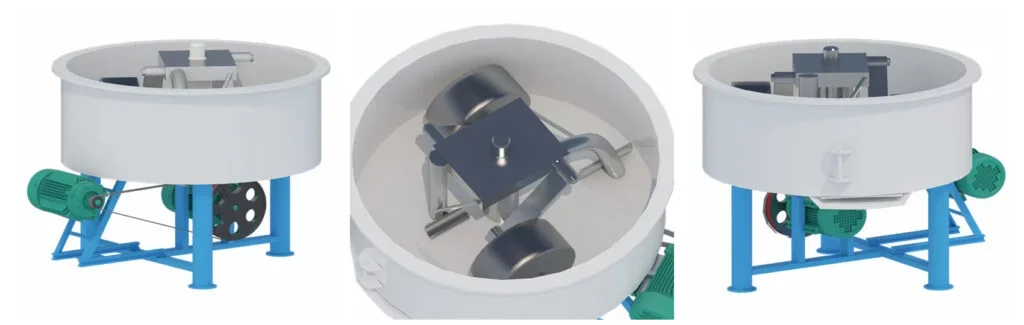

চারকোল পাউডার মিক্সার

চারকোল বলের ছাঁচনির্মাণ গুণমান এবং জ্বলন কর্মক্ষমতা উন্নত করার জন্য, প্রায়শই একটি উপযুক্ত পরিমাণে বাইন্ডার এবং দহন সহায়ক যোগ করা হয়। চারকোল পাউডার মিক্সার চারকোল পাউডার এবং সংযোজনগুলিকে সমানভাবে মিশ্রিত করতে পারে যাতে পরবর্তী ছাঁচনির্মাণ প্রক্রিয়ার স্থিতিশীলতা নিশ্চিত করা যায়, কোনও বাধা ছাড়াই।

চারকোল বল মেশিন

ভালভাবে মিশ্রিত চারকোল পাউডার চাপ এবং ছাঁচনির্মাণের জন্য চারকোল বল মেশিনে প্রবেশ করবে। মেশিনটি চাহিদা অনুযায়ী বিভিন্ন স্পেসিফিকেশন এবং আকারের বারবিকিউ চারকোল তৈরি করতে পারে, যেমন গোল বলের প্রকার, বালিশের প্রকার, বর্গাকার প্রকার ইত্যাদি। এটির উচ্চ ঘনত্ব, শক্তিশালী কাঠিন্য এবং সহজে ভেঙে না যাওয়ার সুবিধা রয়েছে।

BBQ চারকোল প্যাকেজিং মেশিন

শেষ ধাপ হল চারকোল বলগুলিকে স্বয়ংক্রিয়ভাবে ওজন, ব্যাগিং এবং সিল করার জন্য BBQ চারকোল প্যাকেজিং মেশিন ব্যবহার করা। প্যাকেজ করা পণ্যটি পরিপাটি এবং সুন্দর, যা পরিবহন এবং বিক্রি করা সহজ করে তোলে এবং ব্র্যান্ডের চিত্রকেও উন্নত করে।

বারবিকিউ কয়লার উৎপাদন লাইনের সুবিধাসমূহ

উচ্চ মাত্রার অটোমেশন: কার্বনাইজেশন থেকে প্যাকেজিং পর্যন্ত পুরো প্রক্রিয়াটি যান্ত্রিকীকৃত, শ্রম সাশ্রয় করে।

চূড়ান্ত পণ্যের ভাল সামঞ্জস্য: কার্বন বলের অভিন্ন স্পেসিফিকেশন, স্থিতিশীল গুণমান।

শক্তিশালী অভিযোজনযোগ্যতা: বিভিন্ন কাঁচামাল অনুসারে প্যারামিটারগুলি সামঞ্জস্য করা যেতে পারে।

বিস্তৃত বাজার সম্ভাবনা: বারবিকিউ চারকোলের শক্তিশালী চাহিদা এবং রপ্তানি বাজারের ধারাবাহিক বৃদ্ধি।

উপসংহার

বারবিকিউ চারকোল উৎপাদন লাইন হল একটি আধুনিক চারকোল প্রক্রিয়াকরণ ব্যবস্থা যা পরিবেশ সুরক্ষা, দক্ষতা এবং অটোমেশনকে একীভূত করে।

বারবিকিউ চারকোল উৎপাদন লাইন সরঞ্জাম বা প্রযুক্তিগত পরামর্শ সম্পর্কে আরও তথ্যের জন্য, অনুগ্রহ করে আমাদের পেশাদার প্রযুক্তিগত দলের সাথে যোগাযোগ করতে দ্বিধা করবেন না।