Superar a época das chuvas na Serra Leoa: Uma história de sucesso com a nossa máquina de secar carvão

Já teve dificuldades em manter os cronogramas de produção quando o tempo não coopera? Este foi o principal desafio enfrentado por um fabricante de carvão na Serra Leoa antes de investirem na nossa máquina de secar carvão de alto desempenho. Ao passar de uma secagem ao sol tradicional ao sistema de sala de secagem industrial controlada, o cliente conseguiu tornar o seu negócio completamente à prova de intempéries.

Esta atualização trouxe retornos imediatos e impactantes: o tempo de produção foi reduzido de vários dias para apenas algumas horas, e a fábrica conseguiu operar continuamente 24/7, independentemente da forte época de chuvas. O resultado é um fornecimento consistente de briquetes de carvão de alta qualidade, sem rachaduras, que lhes permitiu dominar o mercado local.

Contexto e Necessidades do Cliente

A Serra Leoa possui recursos abundantes de biomassa, tornando-se um local ideal para a produção de carvão. No entanto, o país também enfrenta uma longa e intensa época de chuvas, que representa um obstáculo severo para os produtores que dependem da secagem natural.

O cliente, uma empresa em crescimento que produz briquetes de carvão para churrasco a partir de resíduos agrícolas, encontrou uma limitação severa na sua produção devido aos altos níveis de humidade. A sua dependência anterior de secagem ao sol resultava em conteúdo de humidade inconsistente, levando a briquetes difíceis de acender ou que produziam fumaça excessiva.

Eles precisavam urgentemente de uma secadora de briquetes que pudesse proporcionar um ambiente de aquecimento estável, reduzir o conteúdo de humidade para menos de 5%, e garantir que o produto final permanecesse resistente para transporte.

Solução da Shuliy

Para enfrentar os desafios climáticos da África Ocidental, projetámos uma solução robusta de secador de carvão de ar quente em caixa. Este sistema foi concebido para eficiência e facilidade de carregamento. Equipámos a sala de secagem com carrinhos de transporte de alta resistência e bandejas de aço inoxidável otimizadas para fluxo de ar.

O núcleo da solução é um sistema de aquecimento de alta eficiência — compatível com a queima de restos de madeira ou pellets de biomassa — para reduzir os custos operacionais do cliente. O equipamento de secagem de carvão de madeira possui um potente ventilador de circulação de ar quente que garante uma distribuição uniforme do calor por toda a câmara.

Quais são as vantagens da nossa máquina de secar carvão?

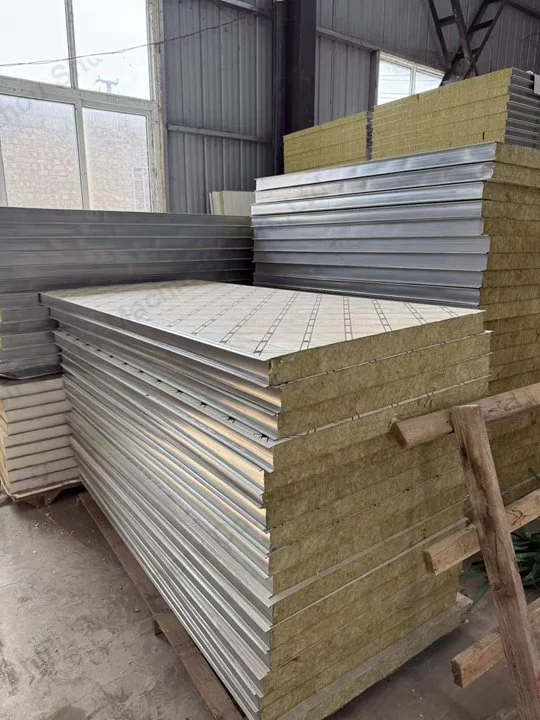

A nossa máquina de secar carvão foi projetada para suportar ambientes industriais exigentes. A caixa de secagem é construída com uma placa de isolamento de poliuretano de alta densidade, que prende eficazmente o calor e reduz significativamente o consumo de energia — um fator crítico para as margens de lucro do cliente.

Ao contrário das secadoras padrão, o nosso sistema inclui um painel inteligente de controlo de temperatura e humidade, permitindo ao operador definir curvas de secagem precisas para evitar que o carvão se rache devido ao aquecimento rápido.

Vantagens do serviço da Shuliy

Sabemos que o envio de equipamentos para Freetown envolve uma longa jornada logística, por isso priorizamos a segurança do produto e a transparência.

Para a embalagem, fomos além das medidas padrão: o armário de controlo eletrónico foi duplamente envolvido em filme à prova de humidade, e a unidade de aquecimento e os conjuntos de ventiladores foram fixados em caixas de madeira reforçadas para evitar danos pela humidade do mar ou impacto.

Também fornecemos uma lista detalhada de carga e fotos para garantir que o cliente pudesse identificar facilmente cada peça na chegada.

Feedback do cliente

O impacto desta máquina no negócio do cliente tem sido transformador. Após receber o equipamento, a nossa equipa de suporte técnico forneceu orientação remota para instalação, ajudando o cliente a montar os painéis de isolamento e a conectar os dutos de ar via chamada de vídeo.

O cliente relatou que a secadora de briquetes de carvão está agora a funcionar sem problemas, e estão encantados com os resultados. Agora podem produzir carvão premium sem fumaça, mesmo durante as chuvas mais intensas, uma capacidade que expandiu significativamente a sua escala de produção.