Làm thế nào để sản xuất than shisha chất lượng cao?

Trong thế giới những người đam mê shisha, chất lượng than quyết định tất cả. Một miếng than cháy lâu, không khói không mùi và chỉ để lại một lớp tro trắng như tuyết sau khi đốt được coi là báu vật hàng đầu. Nó có thể mang lại danh tiếng xuất sắc và giá cao hơn cho một thương hiệu.

Vậy những bí mật nào ẩn sau sự biến đổi từ vỏ dừa hoặc bột tre thông thường thành một khối than shisha chất lượng cao?

Câu trả lời nằm ở việc kiểm soát tỉ mỉ mọi chi tiết sản xuất. Hôm nay, chúng tôi tiết lộ ba yếu tố công nghệ cốt lõi quyết định chất lượng than shisha và chỉ cho bạn cách làm chủ chúng bằng thiết bị chuyên nghiệp.

Lựa chọn và tỷ lệ chất kết dính

Bột than shisha cần chất kết dính để được ép thành hình. Đây là bước dễ sai nhất và là điều phân biệt rõ ràng nhất giữa sản phẩm chất lượng cao và kém.

- Lựa chọn kém: sử dụng chất kết dính hóa học hoặc tinh bột kém chất lượng. Điều này tạo ra mùi khó chịu và khói độc hại trong quá trình cháy, trực tiếp gây nhức đầu và buồn nôn cho người dùng, đồng thời làm hỏng hoàn toàn hương vị trái cây của điếu hookah.

- Lựa chọn tốt: Phải sử dụng tinh bột thực vật tinh khiết, an toàn cho thực phẩm như tinh bột ngô hoặc tinh bột sắn. Những loại này cháy không màu, không mùi, giữ nguyên hương thơm tự nhiên của điếu hookah.

- Tỷ lệ vàng: tỷ lệ chất kết dính là then chốt.

- Quá ít: kết cấu than rời dễ bị vỡ trong quá trình vận chuyển và nứt vỡ trong quá trình cháy.

- Quá nhiều: khối than trở nên quá cứng, khó bắt lửa, và tạo ra nhiều tro hơn trong quá trình cháy.

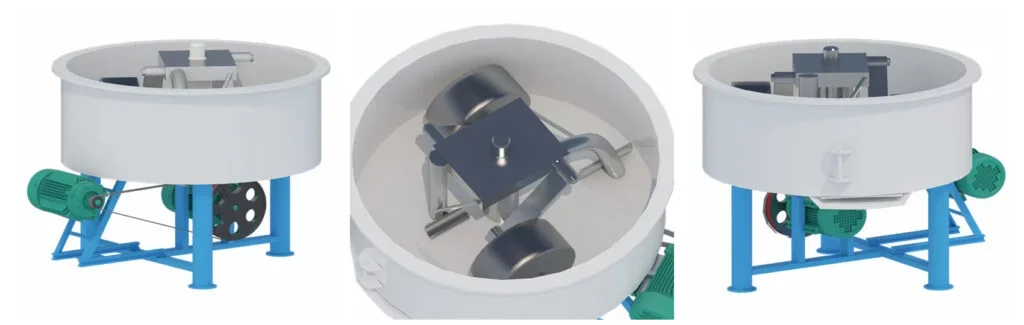

- Làm chủ quy trình: một máy trộn hiệu suất cao là cần thiết. Nó phải pha trộn chính xác keo dán và nước với bột than để đạt được hỗn hợp cực kỳ đồng đều, đảm bảo mọi hạt bột than đều được phủ lớp keo phù hợp. Chỉ có như vậy mới đảm bảo hiệu suất ổn định cho toàn bộ lô hàng.

Áp lực của máy dập viên

Mật độ viên than trực tiếp quyết định thời gian cháy và độ cứng của chúng. Mật độ, đến lượt nó, hoàn toàn phụ thuộc vào áp lực mà máy ép viên có thể tạo ra.

- Áp lực không đủ: sản xuất viên nén mật độ thấp với nhiều khoảng trống bên trong. Điều này dẫn đến:

- Cháy nhanh: Tăng cường tiếp xúc oxy thúc đẩy quá trình tiêu thụ, đòi hỏi thay thế viên nén thường xuyên.

- Tính dễ vỡ: tỷ lệ vỡ cao trong quá trình đóng gói và vận chuyển.

- Hàm lượng tro cao: Cháy không hoàn toàn tạo ra nhiều cặn tro hơn.

- Áp lực lý tưởng: mạnh mẽ máy ép thủy lực cung cấp áp lực ổn định, lớn. Dưới áp lực cao, bột than được nén chặt thành viên nén mật độ cao. Lợi ích:

- 30% thời gian cháy lâu hơn: nhiều nhiên liệu hơn được đóng gói cùng thể tích.

- Bền và chắc chắn: sản phẩm chống vỡ vụn và tạo ra âm thanh giòn khi va chạm.

- Giảm hàm lượng tro và màu sắc trắng hơn: cho thấy quá trình cháy hoàn chỉnh và tinh khiết hơn.

Nghệ thuật của các quy trình sấy

Viên than vừa ép chứa khoảng 30-35% độ ẩm và phải trải qua quá trình sấy để trở thành sản phẩm cuối cùng.

Sấy không đúng: gia nhiệt nhanh và vội vàng quá trình. Điều này gây ra sự khác biệt nhiệt độ quá lớn giữa bên trong và bề mặt viên than.

Độ ẩm bên trong bốc hơi nhanh và giãn nở, làm vỡ lớp vỏ bên ngoài chưa khô hoàn toàn và tạo ra nhiều vết nứt. Viên than nứt được coi là lỗi.

Sấy đúng: một quy trình sấy dần theo giai đoạn là điều cần thiết.

- Giai đoạn làm nóng trước ở nhiệt độ thấp (khoảng 6-8 giờ): sử dụng nhiệt độ thấp hơn để từ từ bay hơi độ ẩm bề mặt, hình thành lớp vỏ ngoài hơi cứng hơn một chút.

- Giai đoạn làm nóng ở nhiệt độ trung bình (khoảng 10-12 giờ): tăng dần nhiệt độ, cho phép nhiệt thấm vào bên trong và từ từ đẩy hơi ẩm cốt lõi ra ngoài.

- Giai đoạn cài đặt nhiệt cao (khoảng 4-6 giờ): cuối cùng, sử dụng nhiệt độ cao để loại bỏ hoàn toàn độ ẩm còn dư, sấy khô và định hình hoàn toàn các khối than.

- Cách để đạt được: phòng sấy chuyên nghiệp là điều cần thiết. Nó phải được trang bị hệ thống điều chỉnh nhiệt độ lập trình và quạt lưu thông khí nóng cưỡng bức để đảm bảo nhiệt độ đồng đều trong toàn bộ buồng. Tuân thủ nghiêm ngặt theo đường cong nhiệt độ cài đặt trước đảm bảo tỷ lệ thu hoạch vượt quá 99%.

Kết luận

- Sử dụng chất kết dính đúng là cam kết đối với sức khỏe người dùng.

- Áp dụng đủ áp lực là lời hứa cho hiệu suất sản phẩm.

- Kiên nhẫn chờ đợi sấy khô là sự theo đuổi chất lượng hoàn hảo.

Tất cả những điều này đòi hỏi một dây chuyền sản xuất chuyên nghiệp để bảo đảm quy trình. Thiết bị của bạn sẽ trực tiếp quyết định vị trí thị trường và khả năng sinh lời của sản phẩm.

Sẵn sàng sản xuất than shisha cao cấp chinh phục thị trường chưa? Liên hệ chuyên gia kỹ thuật của chúng tôi ngay hôm nay để thảo luận cấu hình một dây chuyền sản xuất thực hiện tất cả các quy trình quan trọng này!