Como funciona uma máquina de briquetes de carvão desde a alimentação até à formação do briquete final?

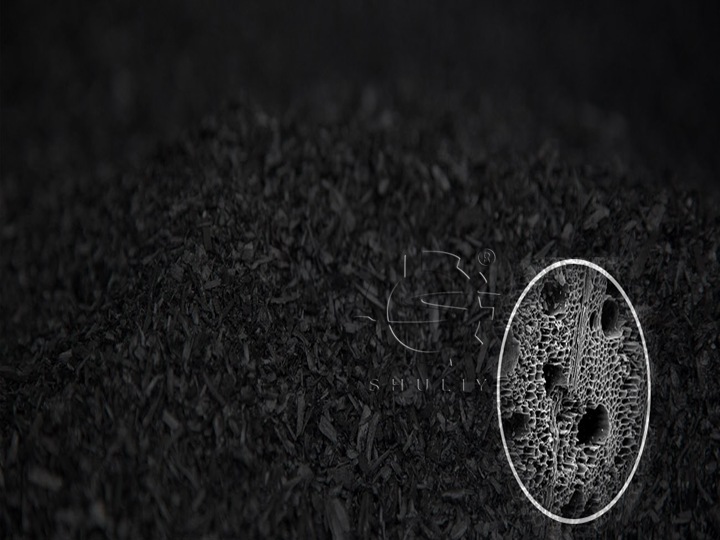

Uma máquina de briquetagem de carvão é um equipamento essencial no processamento de carvão, usinas de biocombustíveis e fábricas de produção de carvão vegetal. O seu trabalho é simples mas crítico—compactar carvão pulverizado solto ou pó de carvão em briquetes sólidos e de alta densidade. Mas como é que a máquina realmente transforma o pó fino em briquetes fortes e uniformes?

Sistema de Alimentação: Preparação do Material para o Processo de Briquetagem

O ciclo de trabalho começa com o alimentador. O carvão pulverizado, o pó de carvão vegetal ou o pó de carbono de biomassa devem cumprir condições específicas:

- Conteúdo de humidade adequado (geralmente 10–15%)

- Tamanho de partícula fino

- Mistura uniforme com aglutinantes (se necessário)

O funil de alimentação da máquina de briquetagem de carvão garante fornecimento contínuo e uniforme de material para evitar entupimentos e garantir pressão de formação estável.

Compressão por parafuso ou pistão: Construindo alta densidade

Dentro da máquina de briquetagem de carvão, um mecanismo de alta pressão comprime o material.

Dependendo do tipo de máquina, isto pode envolver:

- Extrusão de parafuso (tipo extrusor de briquete de carvão)

- Prensagem de duplo rolo

- Compressão por pistão hidráulico

Durante esta fase:

- Vazamentos de ar entre partículas são removidos

- O pó é compactado num estado semicondensado

- Pressão e atrito geram calor suave, melhorando a resistência de ligação

Esta fase de compressão é o núcleo do processo de briquetagem do carvão.

Extrusão e Moldagem: Modelar o Briquete

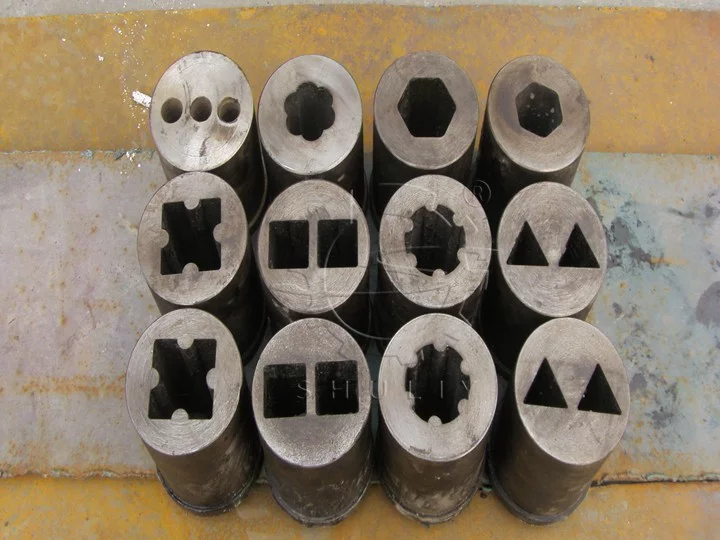

Após a compressão do material, ele é empurrado para a matriz de moldagem.

Moldes diferentes permitem formas de briquete diferentes:

- Briquetes oco

- Briquetes quadrados

- Briquetes redondos

- Briquetes hexagonais

- Briquetes em favo de mel

A máquina de formação de briquetes assegura que cada briquete tenha:

- Densidade uniforme

- Tamanho Consistente

- Superfície lisa

- Resistência estrutural para transporte e queima

A qualidade da forma influencia diretamente a aparência e a durabilidade do briquete.

Sistema de Corte: Controle do Comprimento do Briquete

Na saída de extrusão, um cortador corta os briquetes ao comprimento desejado.

O corte pode ser:

- Manual

- Automático

- Ajustável de acordo com as necessidades de produção

Isso permite que o extrusor de briquetes de carvão mantenha um tamanho de produto consistente para embalar e uso industrial.

Por que a Máquina de Briquetagem de Carvão é Essencial para o Processamento de Combustível?

A máquina de briquetagem de carvão é amplamente utilizada porque resolve problemas comuns com pó de carvão solto:

- Previne poluição por poeira

- Melhora a eficiência de transporte

- Melhora o desempenho de combustão

- Aumenta o poder calorífico

- Fornece combustível uniforme para caldeiras industriais, carvão para churrasco e aquecimento doméstico

A sua alta eficiência e baixo custo operacional tornam-na ideal para pequenas plantas e grandes fábricas industriais de briquetes de carvão.

Uma Solução Completa para a Produção de Briquetes de Alta Qualidade

Compreender como funciona uma máquina de briquetagem de carvão ajuda os produtores a escolher o equipamento certo e a otimizar a produção.

Do alimentação, compressão e extrusão até à moldação final, a máquina garante uma produção estável, briquetes consistentes e alta eficiência.

Conte-nos os seus materiais brutos e necessidades de capacidade—recomendaremos o modelo mais adequado e forneceremos uma solução de processamento completa.