Cách chọn máy tạo than từ vỏ dừa phù hợp cho nhà máy than của bạn

Bạn có dự định thiết lập dây chuyền sản xuất than từ vỏ dừa, nhưng không biết cách chọn lò nung phù hợp?

Máy làm than từ vỏ dừa — còn gọi là lò nung carbon hóa — là trung tâm của nhà máy than của bạn. Chọn đúng mẫu sẽ quyết định hiệu quả sản xuất, chất lượng than và lợi nhuận tổng thể của bạn.

Trong hướng dẫn này, chúng tôi sẽ giải thích những điều cần xem xét khi chọn lò nung carbon hóa vỏ dừa, so sánh các loại lò khác nhau và cách tối đa hóa lợi nhuận đầu tư của bạn với thiết bị phù hợp.

Hiểu vai trò của máy làm than từ vỏ dừa

Máy làm than từ vỏ dừa chuyển đổi vỏ dừa thải thành than chất lượng cao qua quá trình nung ở nhiệt độ cao, hạn chế oxy gọi là quá trình carbon hóa.

Các lò nung carbon hóa hiện đại có đặc điểm:

- Liên tục cấp và xả

- Hệ thống tái chế khí đốt trong quá trình đốt trong

- Hệ thống thu hồi năng lượng và làm sạch khói

Những đổi mới này cho phép nhà sản xuất đạt được hoạt động không khói, phát thải thấp và sản lượng than ổn định, làm cho chúng trở thành lựa chọn lý tưởng cho các doanh nghiệp sản xuất than thân thiện với môi trường.

Các loại máy làm than từ vỏ dừa

Khi chọn thiết bị, điều quan trọng là phải hiểu sự khác biệt giữa các loại lò nung có sẵn.

Lò carbon hóa theo mẻ

Phù hợp cho các startup quy mô nhỏ

- Đầu tư ban đầu thấp

- Tải và xả thủ công

- Công suất sản xuất: 300–500 kg/ngày

Ưu điểm: cấu trúc đơn giản, dễ vận hành

Nhược điểm: công sức lao động cao, thời gian carbon hóa lâu hơn

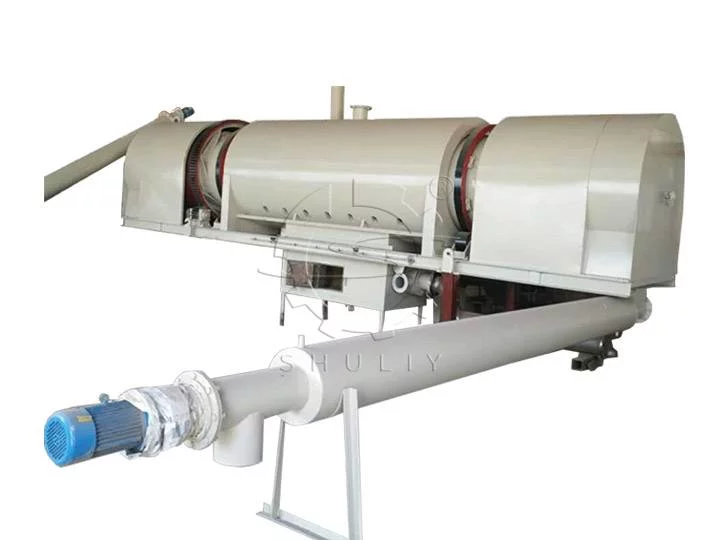

Lò carbon hóa vỏ dừa liên tục

Lý tưởng cho các nhà máy than trung bình đến lớn

- Hoạt động hoàn toàn tự động

- Liên tục cấp và xả

- Công suất sản xuất: 1–5 tấn/ngày

Ưu điểm: hiệu quả cao, sản lượng ổn định, thu hồi năng lượng

Nhược điểm: đầu tư cao hơn một chút nhưng thời gian hoàn vốn ngắn hơn

Máy làm than từ vỏ dừa có lợi nhuận nhất ở đâu?

Các quốc gia như Indonesia, Philippines, Malaysia, Nigeria và Ghana có nguồn cung cấp vỏ dừa lớn, khiến chúng trở thành thị trường lý tưởng để thiết lập các nhà máy than hoạt tính từ vỏ dừa.

Các khu vực này cũng có chi phí lao động thấp và nhu cầu xuất khẩu mạnh cho than BBQ và than shisha, đảm bảo lợi nhuận ổn định.

Tại sao chọn máy làm than từ vỏ dừa của chúng tôi?

Nhà máy của chúng tôi cung cấp dây chuyền sản xuất than hoạt tính từ vỏ dừa, với những lợi thế về thiết bị bao gồm:

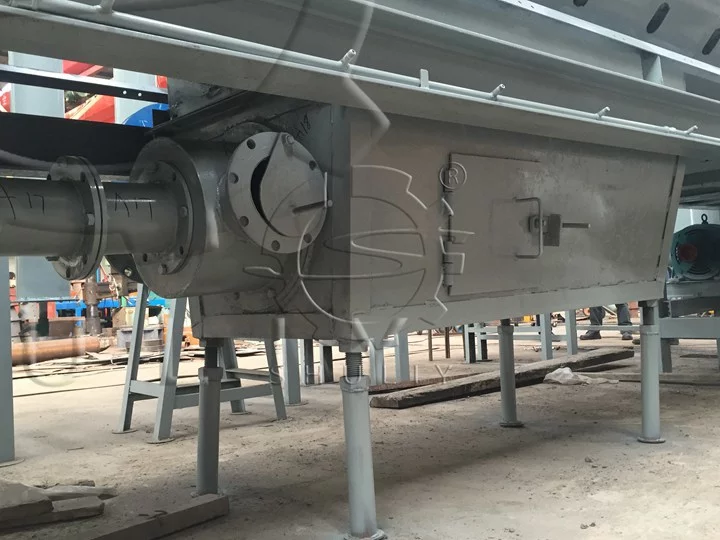

- Thiết kế lò nung carbon hóa liên tục tiên tiến

- Hệ thống thu hồi năng lượng để tái sử dụng khí cháy có thể đốt được

- Cấp liệu tự động, xả và xử lý khói

- Hỗ trợ kỹ thuật 24/7 và dịch vụ lắp đặt tại chỗ

Máy của chúng tôi được sử dụng rộng rãi ở Indonesia, Malaysia, Thái Lan và châu Phi, giúp khách hàng sản xuất than không khói chất lượng cao với tiêu thụ năng lượng thấp và ROI nhanh.

Bắt đầu nhà máy than từ vỏ dừa của bạn với sự tự tin!

Chọn đúng máy làm than từ vỏ dừa là bước đầu tiên và quan trọng nhất để xây dựng một doanh nghiệp than có lợi nhuận.

Dù bạn là một startup nhỏ hay đang mở rộng nhà máy hiện có, các kỹ sư của chúng tôi có thể thiết kế giải pháp tùy chỉnh dựa trên nguyên liệu thô, công suất sản xuất và ngân sách của bạn.

Liên hệ với chúng tôi hôm nay để được tư vấn miễn phí và báo giá máy, bắt đầu bước đầu tiên hướng tới dây chuyền sản xuất than từ vỏ dừa có lợi nhuận của bạn!