Materias Primas Adecuadas para la Producción de Carbón para Barbacoa y Métodos de Selección

¿Por qué la selección de materias primas es fundamental para la producción de carbón vegetal? Para los fabricantes de carbón vegetal, las materias primas son el factor central que determina la calidad del producto, el rendimiento de la combustión y la competitividad en el mercado.

Las materias primas de alta calidad pueden producir carbón vegetal con largos tiempos de combustión, bajas emisiones de humo y polvo, y una producción de calor estable, mejorando así la experiencia del usuario y obteniendo precios de mercado más altos.

Por el contrario, las materias primas inadecuadas pueden dar lugar a carbón vegetal quebradizo, combustión irregular e incluso olores desagradables, lo que puede dañar la reputación y las ventas del cliente.

¿Qué hace que una materia prima sea buena?

Antes de adentrarnos en tipos específicos, es importante comprender las características clave de las materias primas que determinan la calidad del carbón vegetal para barbacoa:

- Alto contenido de carbono y alta lignina: estas son las bases para el alto valor calórico del carbón y su largo tiempo de combustión. Generalmente, cuanto mayor es la densidad de la madera, mayores son estos contenidos.

- Bajo contenido de cenizas: el carbón de barbacoa de alta calidad deja muy pocas cenizas después de la combustión, una métrica muy valorada en el mercado premium.

- Bajo contenido de humedad: la humedad en la materia prima debe ser eliminada efectivamente antes de la carbonización, ya que la humedad residual afecta severamente la eficiencia de carbonización y la calidad final.

- Fácil de obtener y rentable: esto es crucial para asegurar la rentabilidad sostenida de su negocio.

Materias primas comunes adecuadas para producir carbón para barbacoa

Cáscara de coco

Ventajas: alta dureza, alta densidad, bajo contenido de cenizas, largo tiempo de combustión, respetuoso con el medio ambiente y sin olor.

Rendimiento del producto: bajo humo y llama estable, alta demanda en los mercados de exportación, especialmente en Europa, Oriente Medio, Japón y Corea del Sur.

Escenarios aplicables: carbón vegetal de alta gama para barbacoa, mercados de exportación.

Madera dura (como roble, arce y eucalipto)

Ventajas: madera dura, alto rendimiento de carbón vegetal y fuerte calor.

Características del producto terminado: fuerte calor y largo tiempo de combustión, adecuado para cadenas de restaurantes.

Escenarios aplicables: restaurantes de barbacoa grandes y hornos industriales.

Bambú

Ventajas: crecimiento rápido, recursos abundantes, bajo costo y corto tiempo de carbonización.

Características del producto terminado: textura uniforme, fácil de encender y fuertes atributos medioambientales.

Escenarios aplicables: mercados de gama media a baja, productos de carbón vegetal respetuosos con el medio ambiente.

Cáscaras (cáscaras de coco de palma, cáscaras de almendra, huesos de melocotón)

Ventajas: recursos abundantes de subproductos, precio bajo, alto poder calorífico.

Características del producto terminado: calor concentrado, ventaja de coste obvia.

Escenarios aplicables: mercados sensibles al precio, producción en masa.

Serrín

Ventajas: fuente estable, fácil de formar, bajo costo, se puede mezclar con otras materias primas.

Rendimiento del producto terminado: se puede convertir en carbón vegetal hecho a máquina de alta uniformidad, adecuado para prensar en carbón vegetal para barbacoa cilíndrico o cuadrado.

Escenarios aplicables: producción de carbón vegetal hecho a máquina, utilización integral de materias primas.

¿Por qué es una línea de producción completa la clave del éxito?

Ahora que comprende la selección de materias primas, ¿cómo puede transformarlas de manera eficiente y consistente en carbón vegetal de alta calidad para asar?

Aquí es donde entra en juego nuestro equipo especializado. Los hornos de tierra tradicionales no solo contaminan el medio ambiente y operan de manera ineficiente, sino que también carecen de un control preciso del proceso, lo que resulta en una calidad de producto inconsistente.

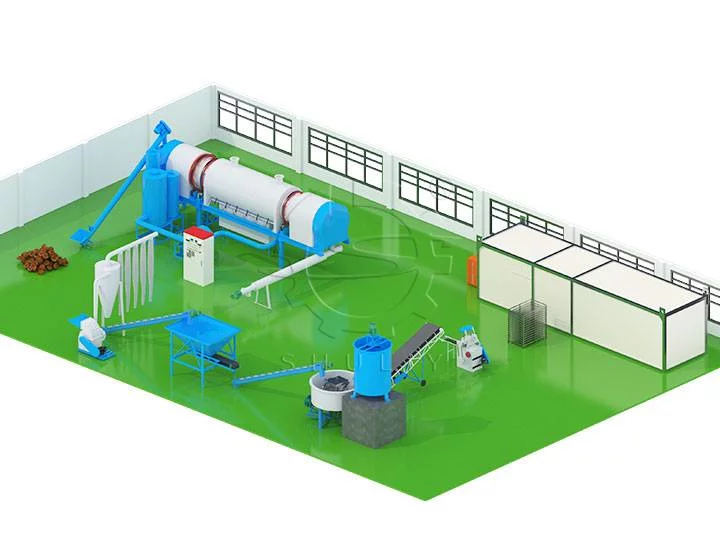

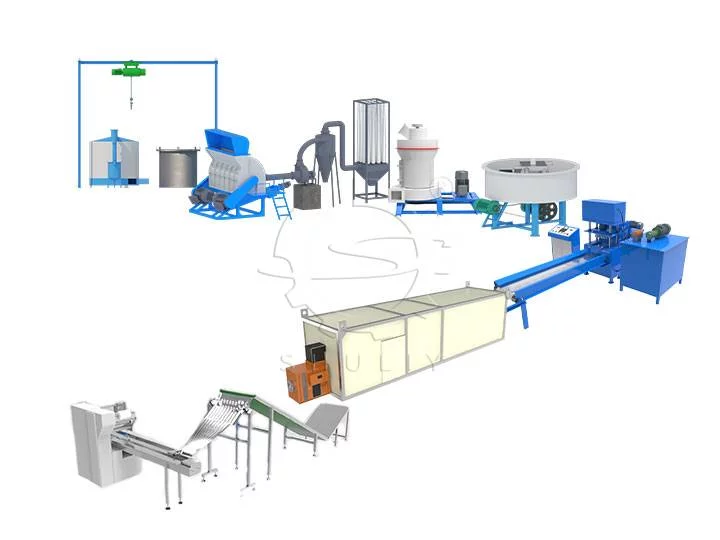

Nuestra línea de procesos de carbón vegetal para barbacoa puede procesar una variedad de materias primas de biomasa, incluidas cáscaras de coco, madera dura, bambú, cáscaras de frutas, serrín, etc., y admite la producción con fórmulas únicas o mixtas.

Toda la línea de producción tiene las siguientes ventajas:

- Alta adaptabilidad: se puede producir carbón vegetal de alta calidad para barbacoa a partir de diferentes materias primas simplemente ajustando los parámetros de carbonización.

- Alto grado de automatización: desde el triturado, secado, carbonización hasta el moldeado, todo el proceso está completamente automatizado, lo que ahorra costos de mano de obra.

- Ahorro de energía y respetuoso con el medio ambiente: se utiliza un sistema de recuperación de gases de combustión para reducir las emisiones y cumplir las normas medioambientales de exportación.

Conclusión

Seleccionar las materias primas adecuadas es el primer paso para garantizar la calidad del carbón vegetal para barbacoa, mientras que elegir una línea de producción que pueda procesar eficientemente una variedad de materias primas es la clave para garantizar el desarrollo a largo plazo de su negocio.

Ya sea que tenga cáscaras de coco, madera dura, bambú o serrín, podemos personalizar la solución de producción de carbón vegetal para barbacoa más adecuada para usted, ayudándole a ingresar rápidamente al mercado y aumentar las ganancias.

¡Contáctenos para un plan de producción y presupuesto gratuitos para sus materias primas!