Dụng cụ bóc vỏ gỗ nào phù hợp với nhu cầu của bạn?

Bóc vỏ gỗ là một phần quan trọng trong quá trình chế biến gỗ, việc lựa chọn công cụ bóc vỏ gỗ phù hợp có thể nâng cao hiệu quả công việc và chất lượng thành phẩm. Trước sự đa dạng của các dụng cụ bóc vỏ gỗ trên thị trường, làm thế nào để chọn được công cụ tốt nhất để bóc vỏ gỗ theo nhu cầu cụ thể? Bài viết này sẽ cung cấp cho bạn lời khuyên thiết thực về loại công cụ, các tình huống sử dụng, loại gỗ và các khía cạnh khác.

Các loại dụng cụ bóc vỏ gỗ chính

Dụng cụ cầm tay

Các dụng cụ bóc vỏ vận hành bằng tay bao gồm dao cạo, rìu chế biến gỗ và máy bóc vỏ di động.

Chúng thường được sử dụng trong chế biến gỗ nhỏ hoặc các tình huống cần xử lý tinh tế.

Chúng có đặc điểm là rẻ tiền, vận hành linh hoạt và không cần điện. Tuy nhiên, chúng kém hiệu quả hơn và phù hợp để xử lý số lượng gỗ nhỏ hơn.

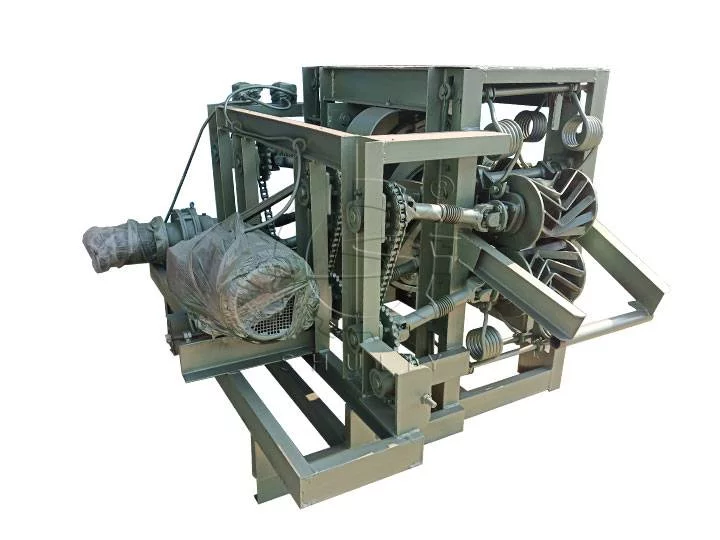

Thiết bị cơ khí

Máy bóc vỏ cơ học bao gồm máy bóc vỏ bằng lưỡi dao, máy bóc vỏ dạng trống, v.v.

Chúng phù hợp hơn với các ngành công nghiệp như công ty chế biến gỗ vừa và nhỏ cần xử lý số lượng lớn gỗ một cách nhanh chóng.

Công dụng của máy bóc vỏ gỗ là tốc độ cao và hiệu quả. Họ có thể xử lý nhiều loại gỗ. Tuy nhiên, chúng cần có chi phí đầu tư và yêu cầu bảo trì thường xuyên.

Những lưu ý khi lựa chọn dụng cụ bóc vỏ gỗ

Cách sử dụng và kích thước

Gia công quy mô nhỏ: nếu bạn chỉ chế biến một lượng nhỏ gỗ, dụng cụ cầm tay có thể là lựa chọn tốt nhất.

Xử lý quy mô lớn: đối với các kịch bản công nghiệp cần xử lý nhanh chóng số lượng lớn gỗ, hãy chọn máy bóc vỏ chuyên nghiệp và hiệu quả.

Các loại gỗ

Gỗ mềm: chúng có thể được xử lý dễ dàng bằng hầu hết các dụng cụ và dụng cụ cầm tay sẽ thực hiện được công việc này.

Gỗ cứng: cần có máy móc hoặc công cụ tự động hiệu quả hơn để đảm bảo việc bóc vỏ triệt để.

Tính di động và hiệu quả

Tính di động: nếu nơi làm việc của bạn liên tục thay đổi, tốt hơn hết bạn nên chọn những công cụ nhẹ và dễ mang theo.

Hiệu quả: để xử lý cường độ cao ở một địa điểm cố định, hãy ưu tiên thiết bị hoàn toàn tự động hoặc bán tự động.

Hiệu quả ngân sách và chi phí

Ngân sách thấp: dụng cụ cầm tay hoặc thiết bị cơ khí nhỏ là những lựa chọn hợp lý.

Ngân sách cao: mặc dù máy bóc vỏ công nghiệp đắt hơn nhưng chúng mang lại lợi thế về độ bền, hiệu quả và chất lượng quy trình, giúp tiết kiệm chi phí hơn về lâu dài.

Bằng cách sử dụng một số yếu tố trên, hy vọng sẽ giúp bạn tìm được dụng cụ bóc vỏ gỗ phù hợp để nâng cao hiệu quả và chất lượng chế biến gỗ.

Shuliy: Nhà cung cấp máy bóc vỏ công nghiệp đáng tin cậy

Nếu bạn đang cân nhắc mua một máy bóc vỏ log công nghiệp, Shuliy Wood Machinery xứng đáng nhận được sự chú ý và tin tưởng của bạn. Chúng tôi có hai loại máy bóc vỏ gỗ để bán: máy bóc vỏ dạng dọc và máy bóc vỏ ngang.

Ưu điểm của máy bóc vỏ gỗ của chúng tôi

Chúng tôi có 13 năm kinh nghiệm nghiên cứu và phát triển chuyên nghiệp trong lĩnh vực sản xuất máy móc chế biến gỗ và máy bóc vỏ gỗ của chúng tôi được khách hàng trên toàn thế giới đánh giá cao.

Cả hai dụng cụ bóc vỏ gỗ đều có thể xử lý nhiều loại gỗ và các khúc gỗ có kích thước khác nhau. Có nhiều mẫu mã đa dạng để lựa chọn, phù hợp với nhu cầu kích thước khác nhau của khách hàng.

Hơn nữa, chúng tôi có thể tùy chỉnh máy theo nhu cầu riêng của khách hàng, chẳng hạn như công suất, kích thước, bánh xe có thể tháo rời, phương pháp cấp nguồn, v.v.

Hãy liên hệ ngay với chúng tôi để tham gia ưu đãi đặc biệt sở hữu dụng cụ bóc gỗ chất lượng cao!

Chạy Video Máy bóc vỏ gỗ