Tại sao sản xuất than củi không thể hoạt động mà không có máy sấy trống quay?

Đảm bảo kiểm soát độ ẩm phù hợp là một trong những bước quan trọng nhất trong quá trình chế biến than. Nếu không có sấy khô ổn định và hiệu quả, chất lượng than cuối cùng sẽ bị ảnh hưởng—viên nén nứt, hiệu quả nung giảm, và tiêu thụ nhiên liệu tăng. Đó là lý do tại sao máy sấy trống quay cho sản xuất than đã trở thành một máy móc thiết yếu trong các nhà máy than hiện đại.

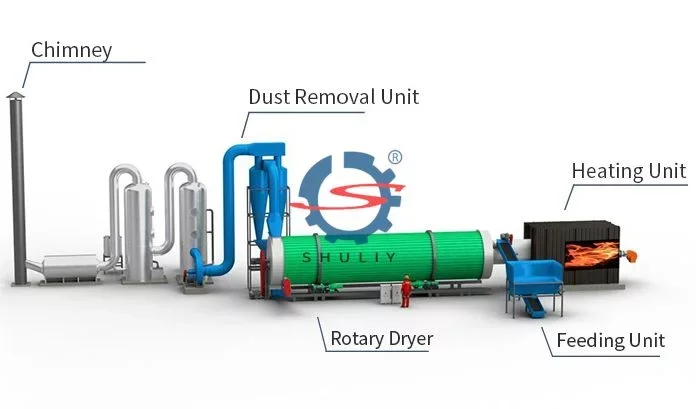

Máy sấy trống quay cung cấp quá trình sấy khô liên tục và đồng đều cho mùn cưa, mảnh gỗ, vỏ dừa, tre, và các loại sinh khối khác, đảm bảo dây chuyền sản xuất than hoạt động trơn tru và hiệu quả.

Kiểm soát độ ẩm ổn định: Nền tảng của than chất lượng cao

Độ ẩm đồng đều là yếu tố then chốt ảnh hưởng đến mật độ, độ cứng và sản lượng nung của than.

Máy sấy trống quay cho sản xuất than đảm bảo:

- Lăn tròn liên tục để phân phối nhiệt đều

- Kiểm soát độ ẩm chính xác từ 50–60% xuống còn 10–15%

- Giảm thiểu dao động sấy khô do thời tiết hoặc độ ẩm

So với phương pháp sấy tự nhiên hoặc sấy bằng luồng khí nhỏ, máy sấy trống quay cho sinh khối đạt được độ ổn định cao hơn nhiều, điều này trực tiếp cải thiện chất lượng viên nén than.

Xử lý liên tục cho các nhà máy than quy mô lớn

Trong các nhà máy hiện đại, dây chuyền sản xuất yêu cầu dòng chảy vật liệu liên tục.

Hệ thống sấy trống quay công nghiệp hỗ trợ:

- cấp liệu và xả liên tục

- Sản lượng sấy khô công suất cao 24/7

- tích hợp liền mạch với lò nung than, máy ép viên, máy nghiền búa, v.v.

Điều này lý tưởng cho các nhà máy sản xuất than lớn xử lý hàng tấn mùn cưa hoặc mảnh gỗ mỗi giờ.

Hiệu quả năng lượng cao hơn và chi phí vận hành thấp hơn

Một máy sấy mùn cưa hoặc máy sấy sinh khối được thiết kế tốt có thể giảm tiêu thụ năng lượng bằng:

- tái sử dụng khí nóng qua cấu trúc trao đổi nhiệt nhiều lớp

- giảm thiểu mất nhiệt với thiết kế trống cách nhiệt

- duy trì hiệu quả sấy cao hơn mỗi kw/h

Khi giá năng lượng tăng trên toàn cầu, máy sấy trống quay hiệu quả cao giúp giảm đáng kể chi phí trên mỗi tấn than sản xuất.

Hiệu quả nung và sản lượng tốt hơn

Độ ẩm quá cao hoặc không đều có thể dẫn đến:

- quá trình nung không hoàn chỉnh

- nội dung carbon cố định thấp hơn

- mức độ tro cao hơn

- độ không ổn định đầu ra

Bằng cách đảm bảo độ ẩm nhất quán trước khi nung, máy sấy trống quay cho sản xuất than cho phép lò nung:

- đốt cháy đều hơn

- giảm thời gian nung

- tăng sản lượng và độ cứng của than

Điều này trực tiếp nâng cao giá trị kinh tế của sản phẩm than cuối cùng.

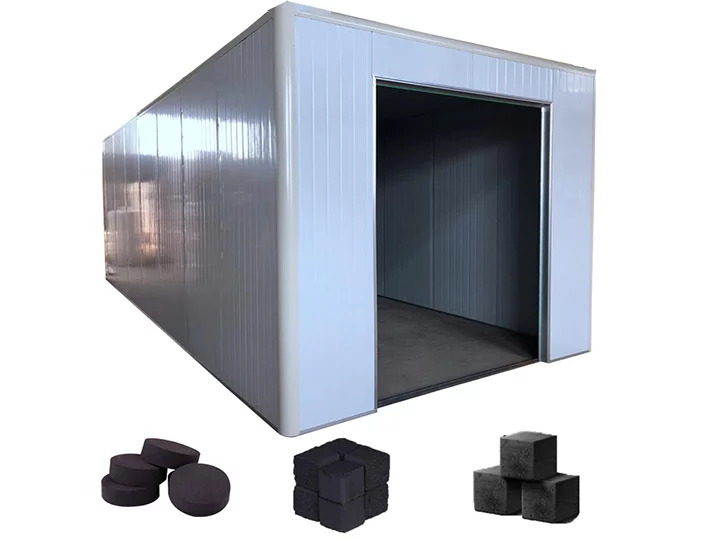

Đa dạng cho nhiều loại sinh khối

Một lợi thế lớn của thiết bị sấy trống là khả năng thích ứng rộng với nhiều loại vật liệu.

Nó có thể xử lý:

- mùn cưa

- dăm gỗ

- mảnh tre

- trấu

- bột vỏ dừa

- sinh khối từ chất thải nông nghiệp

Đối với các nhà sản xuất than làm việc với nguyên liệu theo mùa hoặc trộn lẫn, tính linh hoạt này rất quan trọng.

Thời gian sử dụng thấp và tuổi thọ dài

Một máy sấy trống quay tốt có đặc điểm:

- thùng thép chống mài mòn cao

- Thiết kế cơ khí đơn giản

- tỷ lệ hỏng thấp

- bảo trì dễ dàng hàng ngày

Điều này dẫn đến ít gián đoạn sản xuất hơn và giảm chi phí dài hạn.

Máy sấy trống quay là thiết bị không thể thiếu trong bất kỳ nhà máy than nào

Từ kiểm soát độ ẩm đến hiệu quả sản xuất, không có thiết bị sấy nào sánh bằng máy sấy trống quay cho sản xuất than.

Chúng tôi cung cấp các máy sấy trống quay tiên tiến được thiết kế đặc biệt cho các nhà máy sản xuất than, mang lại hiệu suất đáng tin cậy, tiết kiệm năng lượng và tuổi thọ dài.

Liên hệ với chúng tôi hôm nay để nhận giải pháp sấy khô toàn diện và sơ đồ nhà máy cho dây chuyền sản xuất than của bạn!