功能一览

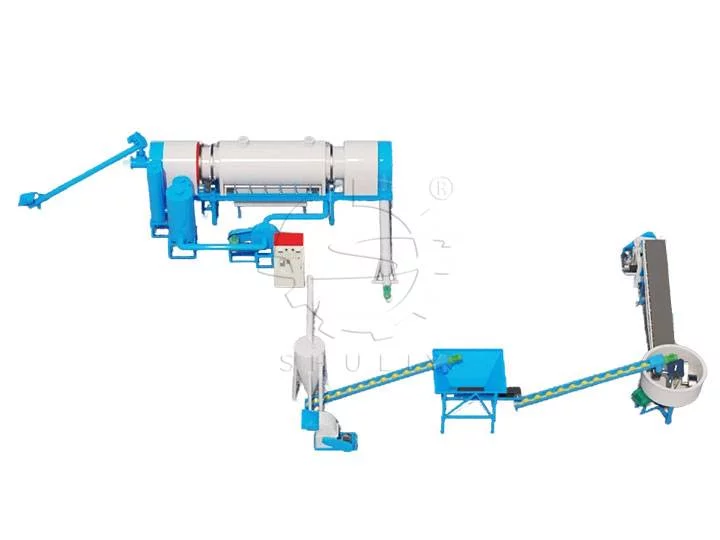

烧烤炭生产线代表了一套系统化的设备组合,专门用于生产高品质的炭,特别设计用于烧烤和烤制目的。

这个复杂的过程涉及将原材料转化为卓越的烧烤木炭砖,以其高效和独特的特性而闻名。从碳化炉到包装机,这条烧烤木炭生产线无缝整合了各种组件,以产生卓越的结果。

完整的烧烤木炭生产线主要包括碳化、破碎、压块、干燥和包装。

烧烤木炭压块的生产过程是什么?

以下是烧烤木炭生产线涉及的过程的一般概述:

原材料准备

The first step involves collecting and preparing the raw materials, which are often wood logs, sawdust, bamboo, coconut shells, or other biomass. These materials need to be dried to ensure consistent quality in the final charcoal. In Shuliy Charcoal Machinery Factory, we have a charcoal drying room and rotary sawdust dryer for you to choose from.

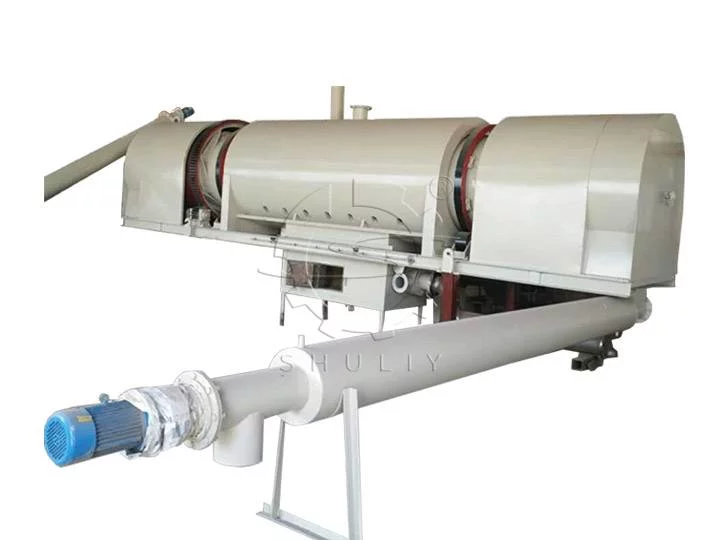

碳化

Carbonization is the process of heating raw materials in the absence of oxygen to remove volatile components and moisture. This results in the conversion of the organic matter into charcoal. The carbonization process can be carried out in a carbonization stove to control temperature and air supply. At the same time, this step is also the most important step in the barbecue charcoal making process.

粉碎

The collected charcoal needs to be crushed to achieve uniform particle sizes. We need to use a charcoal crushing machine to achieve this step. This step can improve the burning efficiency and consistency of the charcoal.

混合与绑定

Depending on the desired characteristics of the final product, binders or additives might be mixed with charcoal. This step can affect factors like burn time and smoke generation. A charcoal powder mixer should be used in this step.

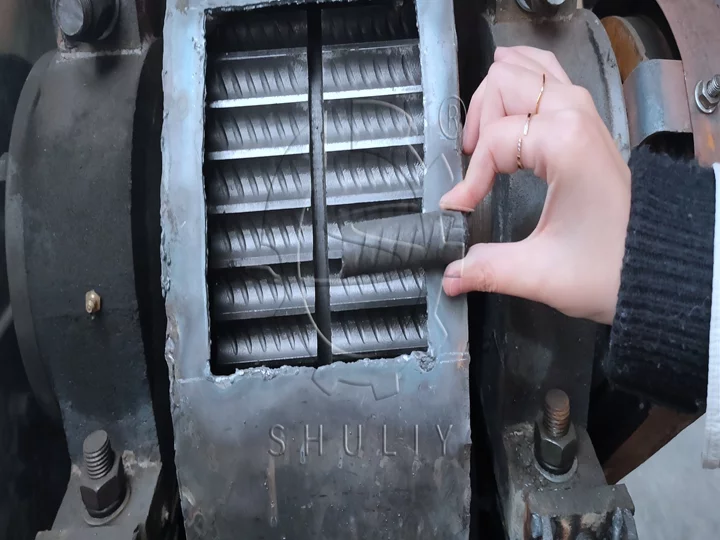

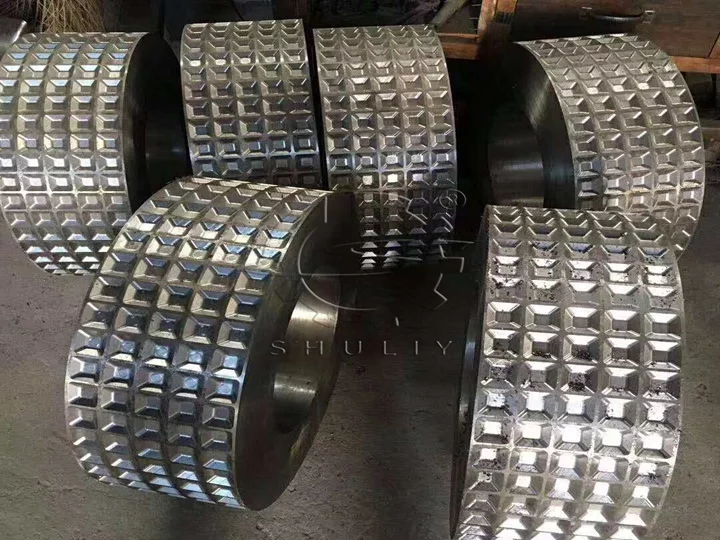

挤压或压块成型

Next comes the most important step – briquetting. The charcoal powder is formed into specific shapes using bbq charcoal briquette press machine. This can make the charcoal easier to handle and use in grills and barbecues. This is also an important step in the BBQ charcoal processing plant. The output of this machine is 1-13t per hour. Therefore, it can meet most of the barbecue charcoal production needs.

包装

The final charcoal product is packaged and ready for distribution and sale. We can use a bbq charcoal packaging machine to pack barbecue charcoal.

一般来说,烧烤木炭的常见包装规格有袋装烧烤木炭、盒装烧烤木炭、散装木炭和吨装木炭。我们的包装机可以根据您的需求生产重量一致的袋装或盒装烧烤木炭。

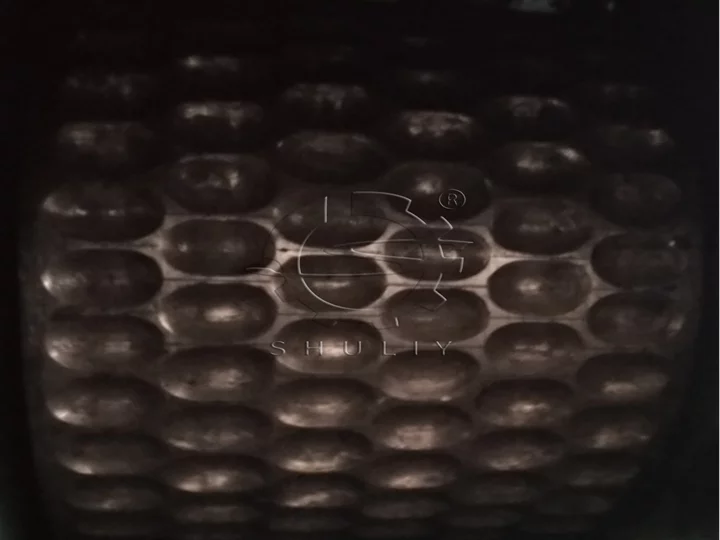

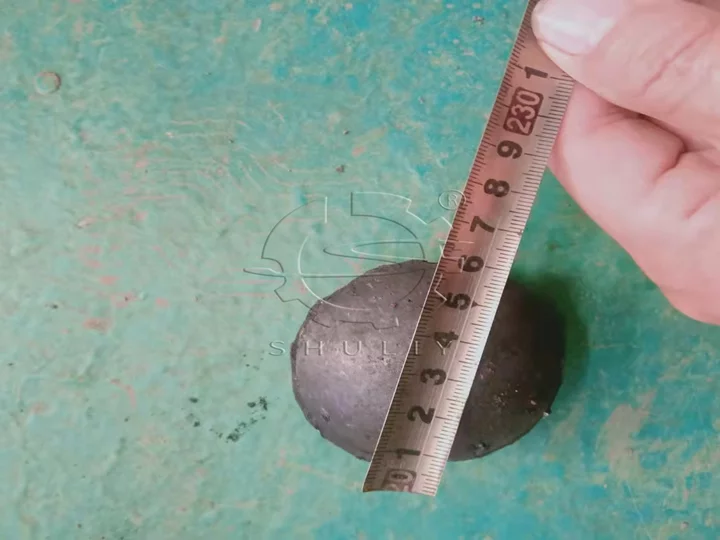

不同形状的模具供您选择

不同形状的烧烤木炭展示

烧烤木炭生产线的灵活性体现在其能够生产不同形状的压块。无论是圆柱形、方形还是定制设计,我们的烧烤木炭生产线都能满足各种偏好,满足多样化的烧烤需求。

水和粘合剂在烧烤木炭加工厂中的作用

水和粘合剂的结合是这一过程的重要方面,因为它有助于原材料的凝聚力。这种混合物促进了不同形状和大小的压块的形成,提高了它们在烤架上的可用性和多功能性。

制作烧烤木炭压块的添加剂

Additives are skillfully incorporated into the mixture to optimize the attributes of the BBQ charcoal briquettes. Tapioca binder and corn flour binder, known for their adhesive qualities, lend structural integrity to the briquettes, ensuring they maintain their shape and functionality throughout the grilling process.

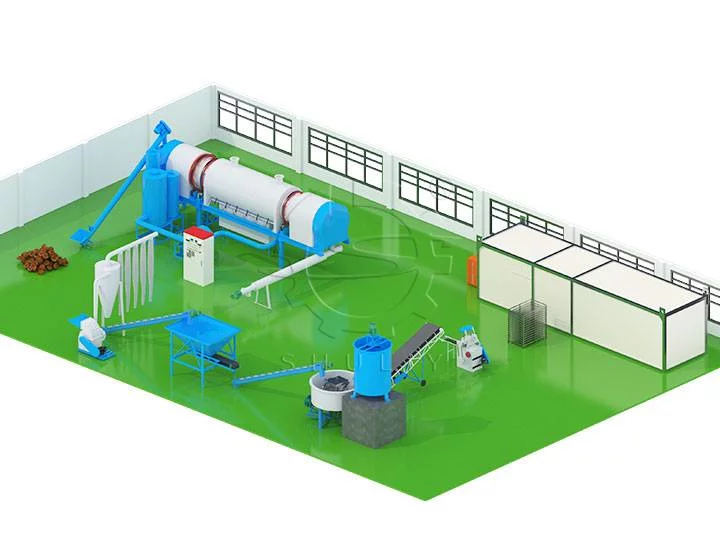

烧烤木炭生产线组件

烧烤木炭生产线的核心组件在优质木炭块的制造中起着关键作用。

烧烤炭生产线的组成部分包括原材料处理设备、碳化设备、炭粉破碎和混合设备、成型设备、干燥设备以及冷却和包装设备。

碳化炉确保高效和可控的碳化,随后是木炭磨粉机将原材料精细研磨成细粉。木炭粉混合机无缝地混合添加剂、水和粘合剂,而烧烤木炭压块机则将混合物成型为所需的形状。干燥机去除多余的水分,包装机则通过安全包装压块完成整个过程。

烧烤木炭生产线流程图

烧烤木炭块厂生产的烧烤木炭块具有无烟、燃烧时间长和无灰残留的特点。这些特性提升了烧烤体验,符合挑剔的烧烤爱好者的需求。此烧烤木炭生产流程图详细展示了从原材料到最终产品的精细进程,涵盖了每个阶段。

罗马尼亚客户购买了一条完整的烧烤木炭生产线

在2021年12月,罗马尼亚客户从我们公司订购了一条完整的烧烤木炭生产线。起初,客户并不信任我们。我们通过发布机器图片、机器视频和视频通话来赢得客户的信任。

此外,我们的销售人员向客户介绍了每款烧烤炭机的详细信息以及我们的售后服务。最后,我们为客户定制了一条每小时产量为5吨的烧烤炭生产线。以下是我们为罗马尼亚客户定制的机器照片及发货照片。

制作烧烤炭块适合使用什么材料?

理想用于这种烧烤木炭生产线的材料包括椰壳炭,以其无烟和更长的燃烧时间而闻名。木炭因其传统魅力而受到喜爱,竹炭因其可持续性而受到重视,也是流行的选择。这些材料的精心挑选构成了完美烧烤木炭压块的基础。此外,硬木、水果木、木屑和其他生物质原料也可以用于制作烧烤木炭。

热销产品

双辊木材去皮机用于木材加工

双辊木去皮机可以处理各种…

生物质废料木材粉碎机

木材粉碎机是一种用于…的机械设备

水平炭化炉

发现我们高效、环保的水平炭炉。完美…

立式带锯机用于木材加工厂

立式带锯锯木厂是一种锯木厂…

圆盘式木材碎片机,用于生产木屑

圆盘式木屑粉碎机是一种机器…

用于稻壳、锯末、竹子的连续炭化机

连续碳化机是一种设备…

水烟炭机,用于制作水烟炭

水烟炭机专门设计用于压缩…

烧烤炭块机

通过更换模具,我们的烧烤木炭压块机…

旋转锯末干燥机 | 锯末干燥机

旋转鼓式锯末干燥机是一种…