Barbecue Charcoal Production line

BBQ Charcoal Production line | Barbecue Charcoal Processing Plant

Barbecue Charcoal Production line

BBQ Charcoal Production line | Barbecue Charcoal Processing Plant

Features at a Glance

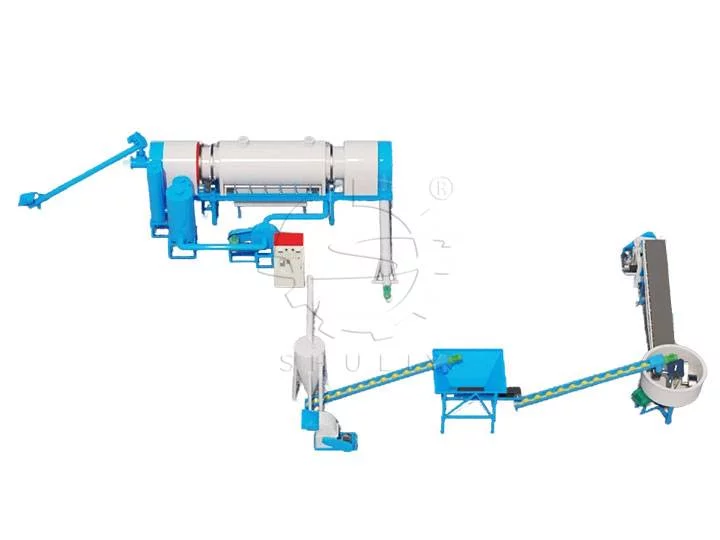

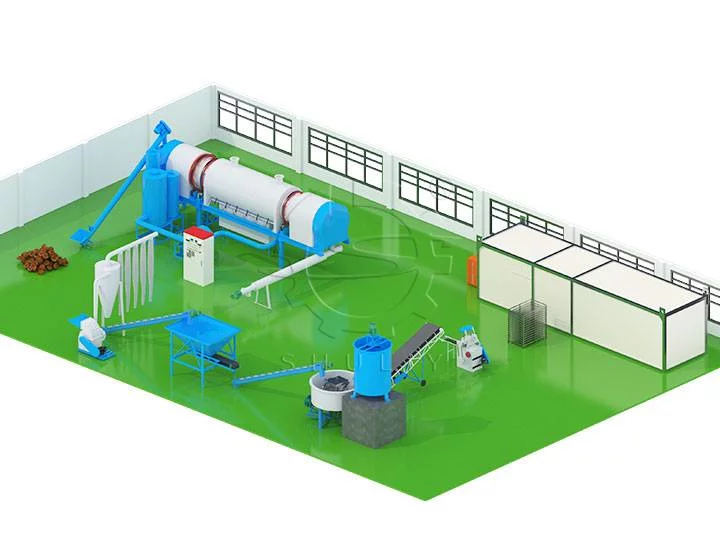

The barbecue charcoal production line represents a systematic assembly of equipment dedicated to the creation of premium-quality charcoal, specifically designed for barbecuing and grilling purposes.

This intricate process involves the transformation of raw materials into exceptional BBQ charcoal briquettes, renowned for their efficiency and distinct attributes. From carbonization stoves to packing machines, this barbecue charcoal production line seamlessly integrates various components to yield outstanding results.

The complete barbecue charcoal production line mainly includes carbonization, crushing, briquetting, drying, and packaging.

What Is the BBQ Charcoal Briquettes Production Process?

Here’s a general overview of the process involved in a barbecue charcoal production line:

Raw Material Preparation

The first step involves collecting and preparing the raw materials, which are often wood logs, sawdust, bamboo, coconut shells, or other biomass. These materials need to be dried to ensure consistent quality in the final charcoal. In Shuliy Charcoal Machinery Factory, we have a charcoal drying room and rotary sawdust dryer for you to choose from.

Carbonization

Carbonization is the process of heating raw materials in the absence of oxygen to remove volatile components and moisture. This results in the conversion of the organic matter into charcoal. The carbonization process can be carried out in a carbonization stove to control temperature and air supply. At the same time, this step is also the most important step in the barbecue charcoal making process.

Crushing

The collected charcoal needs to be crushed to achieve uniform particle sizes. We need to use a charcoal crushing machine to achieve this step. This step can improve the burning efficiency and consistency of the charcoal.

Mixing and Binding

Depending on the desired characteristics of the final product, binders or additives might be mixed with charcoal. This step can affect factors like burn time and smoke generation. A charcoal powder mixer should be used in this step.

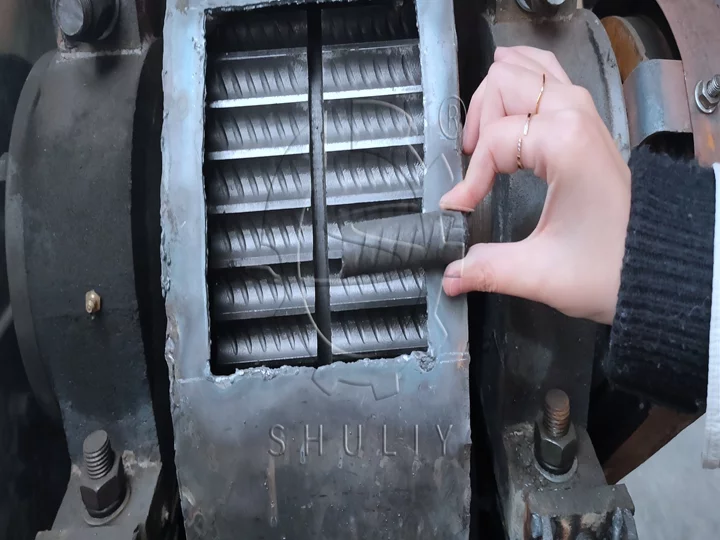

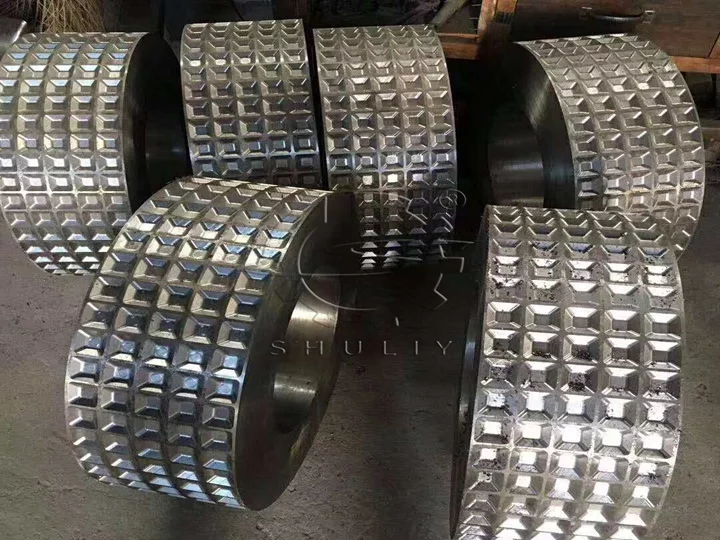

Extrusion or Briquetting

Next comes the most important step – briquetting. The charcoal powder is formed into specific shapes using bbq charcoal briquette press machine. This can make the charcoal easier to handle and use in grills and barbecues. This is also an important step in the BBQ charcoal processing plant. The output of this machine is 1-13t per hour. Therefore, it can meet most of the barbecue charcoal production needs.

Packaging

The final charcoal product is packaged and ready for distribution and sale. We can use a bbq charcoal packaging machine to pack barbecue charcoal.

Generally speaking, the common packaging specifications for barbecue charcoal are bagged BBQ charcoal, boxed BBQ charcoal, bulk charcoal, and tons of charcoal. Our packaging machine can make bagged or boxed barbecue charcoal with a consistent weight according to your needs.

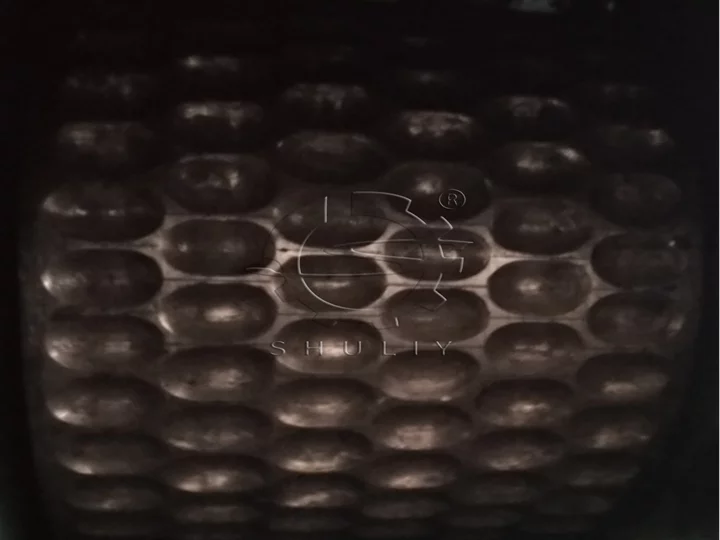

Different Shapes of Molds for Your Choice

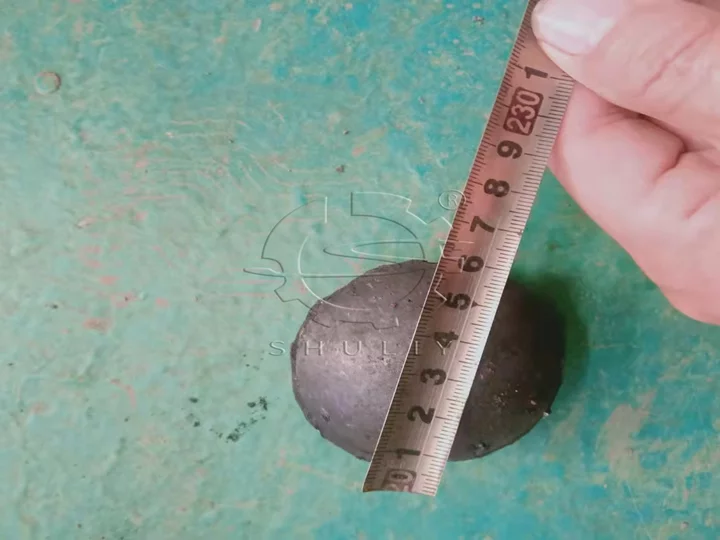

Different Shapes of Barbecue Charcoal Display

The flexibility of the BBQ charcoal production line is highlighted by its ability to produce briquettes of different shapes. Whether cylindrical, square, or custom designs, our barbecue charcoal production line accommodates various preferences, catering to diverse grilling needs.

The Function of Water and Binder in the BBQ Charcoal Processing Plant

The combination of water and binder is an essential aspect of the process, as it contributes to the cohesion of the raw materials. This mixture facilitates the formation of briquettes in varying shapes and sizes, enhancing their usability and versatility on the grill.

Additives for Making BBQ Charcoal Briquettes

Additives are skillfully incorporated into the mixture to optimize the attributes of the BBQ charcoal briquettes. Tapioca binder and corn flour binder, known for their adhesive qualities, lend structural integrity to the briquettes, ensuring they maintain their shape and functionality throughout the grilling process.

Barbecue Charcoal Production Line Components

The core components of the BBQ charcoal production line play a pivotal role in the creation of superior-quality briquettes.

Barbecue charcoal production line components include raw material handling equipment, carbonization equipment, charcoal crushing and mixing equipment, charcoal forming equipment, drying equipment, and cooling and packaging equipment.

The carbonization stove ensures efficient and controlled carbonization, followed by the charcoal grinder that refines raw materials into fine particles. The charcoal powder mixer seamlessly blends additives, water, and binder, while the BBQ charcoal briquettes machine shapes the mixture into desired forms. The dryer eliminates excess moisture, and the packing machine completes the process by packaging the briquettes securely.

BBQ Charcoal Production Line Flowchart

The BBQ charcoal briquettes plant results in BBQ charcoal briquettes characterized by their smokeless nature, longer burning time, and ashless residue. These attributes contribute to an enhanced grilling experience, aligning with the desires of discerning barbecue enthusiasts. This barbecue charcoal production flowchart illustrates the meticulous progression from raw materials to the final product, encompassing each stage in detail.

Romanian Customer Purchased a Complete Barbecue Charcoal Production Line

In December 2021, the Romanian customer ordered a complete barbecue charcoal production line from our company. At first, the customer didn’t trust us. We gained the customer’s trust by posting machine pictures, machine videos, and video calls.

In addition, our sales crystal introduced the details of each BBQ charcoal machine and our after-sales service to the customer. Finally, we customized the BBQ charcoal production line with an output of 5 tons per hour for our customers. Below are the pictures of the machine we customized for our Romanian customer and the delivery pictures.

What Material Is Suitable for Making Barbecue Briquettes?

Among the materials ideally suited for this barbecue charcoal production line are coconut shells charcoal, known for its smokeless and longer burning time attributes. Wood charcoal, appreciated for its traditional charm, and bamboo charcoal, valued for its sustainability, are also popular choices. The meticulous selection of these materials forms the foundation of the impeccable BBQ charcoal briquettes. In addition, hardwood, fruit wood, wood chips, and other biomass raw materials can be used to make barbecue charcoal.

BBQ Charcoal Briquettes Machine

BBQ charcoal briquettes machine refers to an industrial device used…

BBQ Charcoal Packing Machine | Quantitative Packing Machine

BBQ charcoal packing machines are specialized equipment designed to automate…

BBQ Coal Press Machine for Sale in Mexico

In April 2023, a transformative shipment set out from Shuliy…

Shuliy Barbecue Charcoal Maker Machine Shipped to Thailand

In December 2022, a high-quality Barbecue Charcoal Maker Machine departed…

Hot Product

Vertical Bandsaw Mill for Wood Processing Plant

Vertical bandsaw mill is a type of sawmill…

Charcoal Briquette Machine for Bio Coal Briquettes Making

Charcoal briquette machine is a equipment designed to…

Shisha Charcoal Machine for Making Hookah Charcoal

Shisha charcoal machine is specifically designed to compress…

Charcoal Briquettes Dryer for Charcoal Drying

The Shuliy charcoal briquettes dryer is a hot…

Wood Block Machine | Block Pallet Machine

Wood block machine is a machine that turns…

Charcoal Mixer Machine for Mixing Charcoal Powder, Water and Binder

Charcoal mixer machine utilize mechanisms such as rolling,…

Rotary Sawdust Dryer Machine | Sawdust Drying Machine

The rotary drum sawdust dryer machine is a…

Disc Saw for Wood Cutting

Shuliy's disc saw machine can handle many types…

Automatic Shrink Wrap Machine for Packing Charcoal Briquette

Automatic shrink wrap machine is a machine can…