ما هو فرن الكربنة المستمر؟

هل تزعجك أكوام النشارة، قشور الأرز، قشور جوز الهند، أو نفايات زراعية أخرى؟ إنها تشغل مساحة ثمينة وتستغرق وقتًا وجهدًا لإدارتها. لكن ماذا لو كانت هناك آلة يمكنها تحويل هذه المواد إلى فحم عالي القيمة؟ ألن يكون ذلك جذابًا؟

تلك الآلة هي الفرن الكربوني المستمر.

بالنسبة للوافدين الجدد إلى صناعة الفحم، أو للمزارعين وأصحاب المصانع الذين لديهم كميات كبيرة من نفايات الكتلة الحيوية، فهذه بلا شك حل سيغير فهمك. وبصفتها خبيرة ذات سنوات من الخبرة في مجال ماكينات الفحم، يسعد Shuliy Machinery أن تكشف لك أسرارها.

ما هو فرن الكربنة المستمر؟

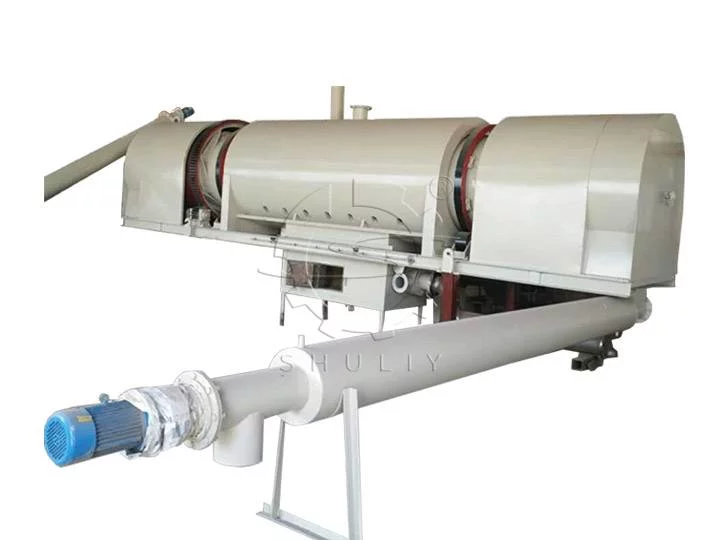

تخيلها كـ «أنبوب سحري مؤتمت بالكامل» صاغته Shuliy Machinery بعناية.

كل ما عليك هو تغذية المواد الخام المسحوقة باستمرار من أحد طرفي الأنبوب. في الطرف الآخر، سيتدفق الفحم عالي الجودة تلقائيًا وباستمرار. العملية بأكملها تتطلب تدخلًا يدويًا ضئيلًا وتعمل في بيئة محكمة الإغلاق تمامًا—نظيفة وصديقة للبيئة.

تلغي طرق الإنتاج المرهقة والمستهلكة للوقت والمليئة بالدخان للأفران الطينية التقليدية أو الأفران المعلقة—تلك الخطوات المملة من «التحميل—الإشعال—الاحتراق البطيء—الانتظار حتى التبريد—تفريغ الفحم».

ماذا يعني مصطلح “مستمر”؟

إنتاج مستمر دون انقطاع: يدخل الخام بينما يخرج الفحم في نفس الوقت، مما يحقق كفاءة إنتاج أعلى بعدة مرات إلى عشرات المرات مقارنة بالمعدات التقليدية.

توفير في العمالة: تتميز أفران الكربنة المستمرة من Shuliy بأنظمة تحكم إلكترونية ذكية PLC عالية الأتمتة. يمكن للعامل أو اثنين بسهولة إدارة خط الإنتاج بأكمله، مما يقلل بشكل كبير من تكاليف العمالة.

جودة ثابتة: تضمن الكربنة المستمرة في ظروف مغلقة وثابتة الحرارة أن كل دفعة من الفحم متجانسة وعالية الجودة باستمرار. تُزال مشاكل الاحتراق الناقص أو الاحتراق الزائد الشائعة في الأفران التقليدية.

كيف يحول النفايات إلى فحم؟

على الرغم من مظهرها المعقد، فإن فلسفة التصميم لدى آلات Shuliy هي «البساطة أسمى درجات التعقيد». يمكن تبسيط تشغيلها إلى ثلاث خطوات أساسية:

التجفيف والتحميل: أولًا، تُغذى المواد الخام إلى مجفف التسخين المسبق الخاص بنا لإزالة الرطوبة الزائدة بكفاءة. ثم ينقلها مِسمار التغذية الآلي بشكل متساوٍ إلى غرفة الكربنة.

كربنة محكمة الإغلاق وإكتفاء ذاتي بالطاقة: داخل وحدة الكربنة، تُسخّن المواد في بيئة خالية من الأكسجين أو منخفضة الأكسجين وحرارة عالية. تُجمع الغازات القابلة للاشتعال المتولدة أثناء الكربنة الأولية عبر نظام تنقية غازات المداخن الحاصل على براءة اختراع لدينا.

بعد التنقية، تُعاد تدوير هذه الغازات لإدامة تسخين الفرن. هذا يحقق «إكتفاء ذاتي بالطاقة»، مما يقلل بشكل كبير من تكاليف الوقود الخارجية.

التبريد وصرف الفحم: بعد الكربنة، يدخل الفحم عالي الحرارة إلى نظام التبريد ذو الغلاف المبرد بالماء المصمم خصيصًا لتقليل درجة الحرارة بسرعة قبل تفريغه بأمان عبر المخرج. يمكن تعبئة هذا الفحم النهائي فورًا دون انتظار طويل.

ما أنواع النفايات التي يمكن استخدامها؟

يمكن استخدام جميع نفايات الكتلة الحيوية السائبة تقريبًا! طالما أن الحجم مناسب—عادةً يتطلب جزيئات صغيرة أو شكل مسحوق—مثل:

نفايات خشبية: نشارة الخشب، رقائق الخشب، نشارة الخيزران

نفايات زراعية: قشور الأرز، مسحوق القش، باجازة قصب السكر، قشور النخيل، قشور جوز الهند

مواد عضوية أخرى: حمأة الصرف الصحي، مخلفات دوائية، إلخ.

فرن الكربنة المستمر من Shuliy للبيع

باختصار، الفرن الكربوني المستمر الذي تصنعه Shuliy Machinery أكثر من مجرد آلة لمعالجة النفايات—إنه نظام فعال للغاية وصديق للبيئة وآلي لإنتاج الفحم. إنه يقدم لك فرصة استثنائية لتحويل الموارد المهملة إلى سلع مربحة للغاية.

لقد ساعدنا بالفعل عملاء في أكثر من 50 دولة ومنطقة حول العالم على تحقيق تحولات ناجحة في أعمالهم من خلال معداتنا. الآن، نأمل أن نساعدك.

لا تتردد! اتصل بخبرائنا الفنيين فورًا. سيقدمون لك استشارة مجانية خاصة بالفرد ويصممون أكثر الحلول فعالية من حيث التكلفة خصيصًا لحالتك.