كل ما تريد معرفته عن الكسارة الشاملة

شراء ماكينة سحق صناعية شاملة يعد استثماراً كبيراً. لتزويدك بفهم أكثر وضوحاً وشفافية عن معداتنا، جمعنا عدة أسئلة أساسية Frequently Asked Questions يطرحها العملاء وتقديم إجابات مركزة وصادقة هنا.

س1: ماذا يمكن أن يعالج هذا الجهاز الشامل بالضبط؟ ماذا لا يمكنه معالجته؟

أ: هذه هي السؤال الأساسي والأهم.

نطاق المواد التي يمكن سحقها واسع للغاية، ويشمل بشكل رئيسي:

- صناديق خشبية/أرضيات بها مسامير: يمكن سحقها مع المسامير والألواح المعدنية الصغيرة المرفقة بالصناديق.

- الأشكال الخشبية/الخشب المهدر: الأشكال المهدرة، الخشب، الأبواب، النوافذ، إلخ، من مواقع الهدم.

- جذور الأشجار/الجذوع/الفروع: بقايا قطع الأشجار أو نفايات تنسيق الحدائق.

- الأثاث المهدور: مثل إطارات الأرائك، والأسرة الخشبية، والطاولات، والكراسي، إلخ. (يتطلب إزالة كميات كبيرة من الرغوة والقماش مسبقًا).

- مواد بالات القش/البامبو: نفايات الزراعة والغابات المضغوطة بواسطة آلات البالات.

مواد لا يمكن أو يجب عدم سحقها:

- قطع معدنية صلبة كبيرة أو ثقيلة: مثل كتل المحركات، والعوارض على شكل I، والألواح الفولاذية السميكة. تم تصميم نظام إزالة المسامير الداخلي للتعامل مع المسامير والأوراق المعدنية الرقيقة المختلطة داخل الخشب، ولا يمكنه معالجة المعادن الثقيلة.

- قطع خرسانية كبيرة أو حجارة: هذه المواد تتمتع بصلابة شديدة وستتسبب في تلف شديد للشفرات وبنية الآلة.

- إطارات، كميات كبيرة من البلاستيك/الأقمشة الناعمة: هذه المواد تتشابك بسهولة حول العمود الرئيسي، مما يؤثر على كفاءة السحق.

الميزة الأساسية: إمكانيتها “المتكاملة” في معالجة نفايات الخشب المعقدة التي تحتوي على المسامير وكميات قليلة من المعدن الرقيق دون الحاجة إلى فرز يدوي مقلق.

Q2: كم من الكهرباء يُستهلك عادةً لتمزيق طن واحد من منصات الخشب؟

أ: هذه مسألة تكلفة تشغيل رئيسية. الإجابة ليست ثابتة وتعتمد على عدة عوامل:

- رطوبة المادة وصلابتها: سحق الخشب الجاف والفضفاض يستهلك طاقة أقل من معالجة جذور الأشجار الرطبة والصلبة.

- اتساق التغذية: التغذية المستمرة والمتساوية تحافظ على استهلاك طاقة أكثر سلاسة وأقل مقارنة بتغذية دفعات كبيرة دفعة واحدة.

- حدة الشفرات: الشفرات الجديدة أو التي تم شحذها حديثًا تعمل بكفاءة أكبر، مما يقلل بشكل طبيعي من استهلاك الطاقة.

نطاق مرجعي: في ظل ظروف التشغيل العادية، عادةً ما يستهلك تشغيل طن واحد من منصات الخشب النفايات الشائعة بين 15-25 كيلواط/ساعة من الكهرباء. هذا تقدير، وقد تختلف الأرقام الفعلية بناءً على نموذج الماكينة الذي اخترته (قوة المحرك) وظروف التشغيل المحددة.

Q3: الشفرات هي أجزاء تآكل. كم تدوم مجموعة منها؟ هل الاستبدال مكلف؟

أ: لأكون صريحاً تماماً، تمثل الشفرات أحد التكاليف التشغيلية الأساسية لـ المكابس الشاملة. كما أن عمرها يعتمد على المواد التي تعالجها.

عوامل تؤثر على العمر:

- “نظافة” المادة: إذا كان الخشب الخاص بك يحتوي على كميات كبيرة من الرمل أو الحصى أو قطع الخرسانة، فإن تآكل الشفرات يتسارع بشكل كبير. ظروف الخشب النقي تعطي أطول عمر للشفرات.

- محتوى المعدن: سحق الصناديق التي تحتوي على مسامير يتسبب في تآكل أكبر بكثير للشفرات مقارنة بمعالجة فروع الخشب النقي.

- مرجع عمر الخدمة: عند معالجة الخشب النظيف نسبيًا، يمكن لمجموعة من الشفرات الحفاظ على الإنتاج ل800-1500 طن قبل الحاجة إلى إعادة الطحن أو الاستبدال.

شفاراتنا مصنوعة من فولاذ سبائك عالي القوة ومتين ومصممة لإمكانية إزالتها وإعادة الطحن عدة مرات. عادةً ما يمكن إعادة طحن مجموعة الشفرات 2-3 مرات، مما يقلل بشكل كبير من تكاليف التشغيل طويلة الأجل.

تكلفة الاستبدال: نقدم ملحقات الشفرات الأصلية بأسعار تنافسية للغاية. مقارنةً باستثمار في الجهاز بأكمله، فإن تكلفة استبدال الشفرات بشكل فردي يمكن تحملها تماماً.

Q4: كيف يبدو المنتج النهائي بعد السحق؟ هل يمكن تعديل الحجم؟

أ: المادة الناتجة عن الماكينة الشاملة تكون على شكل رقائق أو كتل، والتي نطلق عليها "رقائق الخشب" أو "شرائح".

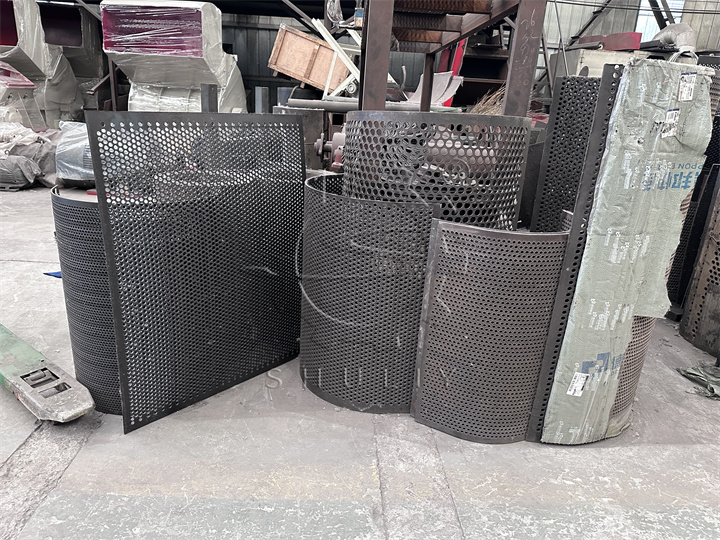

الحجم النهائي: يعتمد الحجم النهائي بشكل أساسي على فتحة شبكة الشاشة في أسفل الجهاز. يتم سحق المادة بشكل متكرر داخل غرفة السحق حتى تصبح أصغر من فتحة الشبكة قبل التفريغ.

تعديل الحجم: نعم، يمكن تعديل الحجم. يمكننا تهيئة الشاشات بفتحات مختلفة (مثلاً 3 سم، 5 سم، 8 سم) وفقاً لاحتياجاتك. ببساطة استبدال الشاشة يغير حجم الإخراج لتلبية احتياجات عملياتك اللاحقة.

س5: ما مدى فعالية الوظيفة الأكثر أهمية في هذه الآلة - إزالة المسامير؟

أ: إزالة المسامير هي الوظيفة الأساسية لدينا في المفرمة الشاملة. معداتنا تستخدم نظام فصل مغناطيسي قهري.

مبدأ العمل: يتم نقل المادة المطحونة عبر حزام ناقل التفريغ. عند نهاية الحزام، نركب أسطوانة مغناطيسية قوية.

مع مرور المادة، تسقط رقائق الخشب طبيعياً بفعل جاذبية، بينما تُجذب الشوائب المعدنية مثل المسامير والقطع المعدنية إلى سطح الأسطوانة بقوة. ومع دوران الأسطوانة إلى الجانب المقابل، تفقد هذه الشوائب جاذبيتها وتسقط في حاوية نفايات مخصصة.

معدل إزالة المسامير: تحت ظروف التشغيل العادية، يتجاوز معدل إزالة المسامير 95%. وهذا لا يحمي فقط المعدات التالية من التلف (مثل مكابس الخشب وبكرات الاصطناعية) ولكنه يضمن أيضاً أن شرائح الخشب الناتجة أنقى، وتحقق أسعار سوق أعلى.

Q6: ما سعر المكبس الشامل؟

أ: سعر ماكينة السحق الشاملة ليس “سعرًا ثابتاً” لأنه نظام قابل للتخصيص. السعر يتكوّن أساساً من المكونات التالية:

- نموذج الوحدة الرئيسية: نحن نقدم نماذج متعددة بسعات معالجة تتراوح من عدة أطنان إلى عشرات الأطنان في الساعة. النماذج الأكبر تتطلب أسعارًا أعلى.

- تكوين الطاقة: يمكنك الاختيار بين محرك كهربائي أو محرك ديزل، كل منهما بأسعار مختلفة.

- المعدات الداعمة: عادةً ما تشمل السعر الوحدة الرئيسية، حزام التغذية، حزام التفريغ، ونظام الفصل المغناطيسي. ومع ذلك، إذا كنت بحاجة إلى أحزمة ناقلة أطول أو معدات إضافية مثل قلاب الأخشاب أو نظام جمع الغبار، فسيتغير السعر وفقًا لذلك.

نوصي بشدة

اتصل بمهندسي المبيعات لدينا وقدم تفاصيل عن المواد الخاصة بك وخرج المنتج المطلوب. سنخصص لك الحل الأنسب ونقدم عرضاً دقيقاً ومفصلاً.