What Is Coconut Shell Charcoal Used For?

Coconut shell charcoal is a versatile and sustainable product that finds its utility across various industries and everyday applications. Extracted from the hard outer shell of coconuts, this type of charcoal undergoes a specialized carbonization process, resulting in a high-quality material prized for its purity and eco-friendly characteristics.

Utilization in Cooking and Grilling

One of the primary uses of coconut shell charcoal is in cooking and grilling. Its clean-burning and long-lasting properties make it a preferred choice for BBQ enthusiasts and professional chefs alike. The charcoal burns hotter and longer than traditional wood charcoal, providing an even heat source ideal for grilling meats, vegetables, and seafood, imparting a distinct and appetizing flavor to the food.

Air and Water Filtration

Beyond culinary applications, coconut shell charcoal plays a pivotal role in environmental conservation. Its porous structure makes it highly effective in air and water filtration systems. Activated carbon derived from coconut shells is widely used in water purification processes, effectively removing impurities and contaminants, thereby enhancing water quality for both industrial and domestic purposes. Moreover, in air filtration systems, efficiently absorb odors and pollutants, contributing to improved air quality.

Agricultural and Horticultural Uses

In agriculture and horticulture, coconut shell charcoal serves multiple purposes. As a soil amendment, it enhances soil structure and fertility, promoting better water retention and aeration for plant growth. Additionally, it acts as a natural and sustainable alternative to chemical-based fertilizers, providing essential nutrients to the soil. Moreover, it can be used as a component in potting mixes, contributing to healthier plant growth and root development.

Manufacturing Process of Coconut Shell Charcoal

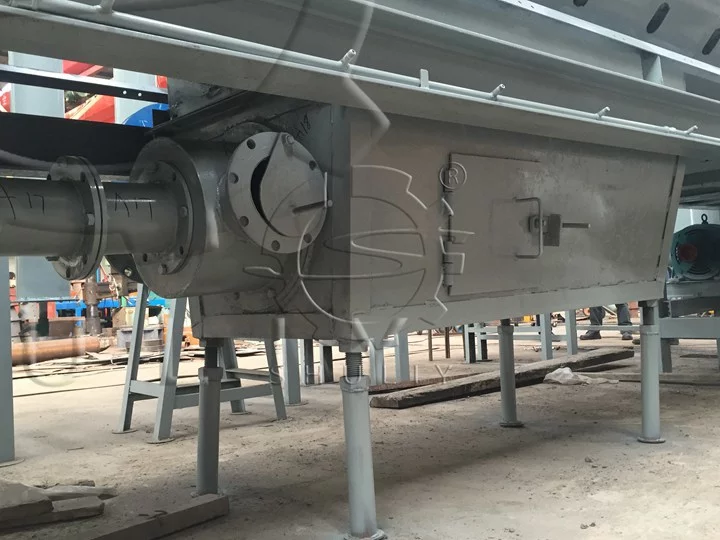

The manufacturing process of coconut shell charcoal involves several key stages. Initially, the coconut shells are collected and dried to reduce moisture content. Subsequently, these dried shells undergo carbonization in a specially designed carbonizing machine, where they are heated in the absence of oxygen, transforming the shells into charcoal through the pyrolysis process. This process removes volatile components and produces a high-carbon, porous material.

After carbonization, the charcoal goes through activation, where it is treated with oxidizing gases at high temperatures. This activation process increases the charcoal’s porosity, creating a vast network of pores that enhances its adsorption capabilities. The final product, activated coconut shell charcoal, is then crushed and sieved to achieve the desired particle sizes suitable for various applications.

In a word, coconut shell charcoal’s versatility extends far beyond mere grilling purposes. Its eco-friendly nature, coupled with its effectiveness in diverse applications such as filtration, agriculture, and more, makes it a valuable and sustainable resource. The meticulous manufacturing process ensures the production of high-quality charcoal that continues to benefit numerous industries and contribute to a greener, more sustainable future.