Wood Pallet Block Production Line

Wood Pallet Block Processing Plant | Sawdust Pallet Block Production Line

Wood Pallet Block Production Line

Wood Pallet Block Processing Plant | Sawdust Pallet Block Production Line

Features at a Glance

Wood pallet block production line is a series of interconnected machines and equipment designed to efficiently and systematically produce wood blocks. These production lines are commonly used in industries that require large-scale production of wood blocks, such as the construction, crafts, and furniture industries.

What Is the Wood Block Making Process?

The wood block production line typically includes the following key components:

- Wood Cutting and Preparation: This stage involves cutting the wood into smaller pieces, such as wood chips, sawdust, or wood shavings, which will serve as the raw materials for making the wood blocks.

- Drying System: The wood materials need to be dried to reduce their moisture content. Low moisture content ensures better bonding and durability of the final wood blocks.

- Wood Block Machine: The heart of the production line, the wood block machine, is used to compress and mold the wood materials into desired block shapes and sizes. The machine applies high pressure and heat to the raw materials, allowing them to bind together to form solid wood blocks.

- Cutting and Finishing: The wood blocks may undergo further processing, such as trimming and finishing, to achieve the desired dimensions and surface quality.

- Quality Inspection: During and after the production process, quality inspection is performed to ensure that the wood blocks meet the required standards and specifications.

- Packaging and Storage: Once the wood blocks pass the quality check, they are packaged and stored for distribution or further use.

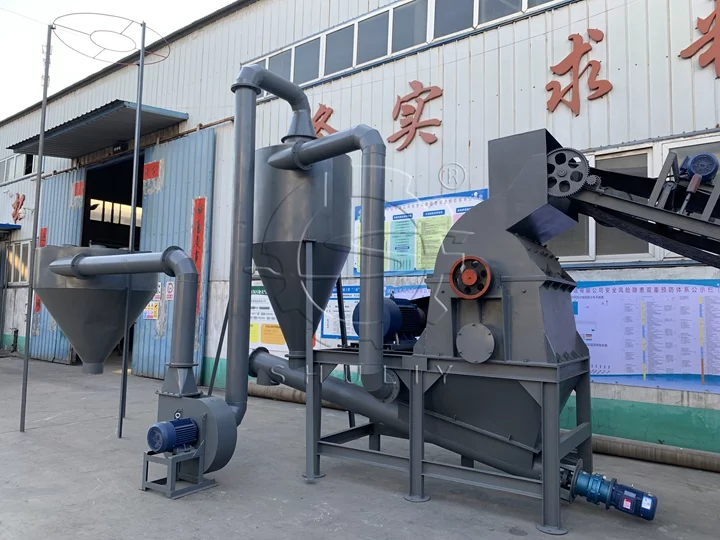

What Machines Are Included in the Wood Pallet Block Production Line?

Wood Chipper or Wood Shaving Machine: These machines are used to reduce raw wood into chips or shavings in preparation for further processing.

Wood Hammer Mill: Wood Hammer mill is to pulverize crushed wood chips, wood shavings, and other biomass materials into sawdust. Such material is easier to be made into wood blocks.

Wood Dryer Machine: Dry wood chips or shavings to reduce the humidity of wood raw materials and improve the efficiency and quality of subsequent processing.

Mixer (Mixer): It is used to mix dried wood chips, wood chips, shavings, or small wood fragments with urea-formaldehyde resin to form a highly plastic and strong mixture.

Sawdust Block Press Machine: This is the core machine of the entire wood pallet block production line, which uses high temperature and pressure to process the mixture into wood blocks of various specifications and sizes.

Automatic Wood Block Cutting Machine: It is used to cut the formed wood blocks into the required size and size to meet the customized needs of different customers.

Where to Buy Wood Block?

- Local Hardware Stores: Many hardware stores or lumberyards carry a variety of wood blocks suitable for various applications. You can visit these stores in person and choose the wood blocks that meet your requirements.

- Online Retailers: Numerous online retailers specialize in selling wood blocks. Websites like Amazon, eBay, and other woodworking supply stores offer a wide range of wood blocks in different sizes and types.

- Specialty Wood Suppliers: Some companies specialize in providing specific types of wood blocks for particular applications. They may offer a more extensive selection of wood types and finishes.

- Woodworking and Craft Stores: Stores that cater to woodworking enthusiasts or crafters often stock wood blocks suitable for smaller projects and artistic endeavors.

- Sawmills or Timber Yards: If you prefer to buy wood blocks directly from the source, you can contact local sawmills or timber yards. They may have custom-cut wood blocks or leftover pieces that can be repurposed.

Features of Shuliy Wood Pallet Block Production Line

- Comprehensive and Efficient Process: The wood pallet block production line is designed to encompass the entire process of wood pallet block manufacturing, starting from raw material preparation to the final product. It streamlines the entire production cycle, ensuring efficiency and reduced downtime.

- Advanced Wood Block Machine: At the core of the wood block production line lies the state-of-the-art wood block machine. This machine is engineered to apply high pressure and temperature, effectively molding the wood chips, sawdust, or shavings mixed with resin into durable and high-quality wood pallet blocks.

- High Automation: Shuliy has integrated advanced automation into the wood block production line, reducing manual labor and ensuring consistent output quality. Automated processes enhance productivity and reduce the risk of errors during production.

- Robust and Durable Construction: The wood block making machine used in the wood pallet block production line is built with high-quality materials, ensuring longevity and reliability even under heavy-duty usage. This robust construction contributes to the sawdust pallet block production line’s overall durability.

Finished Product Display

If you have a requirement for the wood pallet block production line, don’t hesitate to reach out to Shuliy Charcoal&Wood Machinery. We are your trusted partner in crafting a greener and more sustainable future.

Wood Block Machine | Block Pallet Machine

Wood block machine, also known as a wood block making…

Sawdust Block Making Machine Sold to Indonesia

On the wave of sustainability, a high-quality sawdust block making…

What is the Application of Wood Sawdust Block Making Machine?

In the world of modern manufacturing, wood sawdust block making…

Hot Product

Automatic Shrink Wrap Machine for Packing Charcoal Briquette

Automatic shrink wrap machine is a machine can…

Horizontal Charcoal Furnace

Discover our efficient, eco-friendly horizontal charcoal furnace. Perfect…

Carbonization Furnace for Charcoal Making

Three different types of carbonization furnaces are used…

Double Roller Wood Debarker Machine for Wood Processing

Double roller wood debarker machine can handle various…

Disc Wood Chipper for Log Chips Production

Disc wood chipper is a type of machine…

Coconut Shell Charcoal Making Machine for Turning Coconut Husk into Charcoal

We have three different types of coconut shell…

Drum Wood Chipper for Making Wood Chips

Drum wood chipper is a specialized equipment used…

Animal Feed Pellet Machine

Animal feed pellet machine can be used in…

Honeycomb Charcoal Briquette Machine for Making Honercomb

Honeycomb charcoal briquette machine, also known as a…