Coconut Shell Charcoal Making Machine for Turning Coconut Husk into Charcoal

Coconut Charcoal Making Machine | Coconut Shell Charcoal Machine

Coconut Shell Charcoal Making Machine for Turning Coconut Husk into Charcoal

Coconut Charcoal Making Machine | Coconut Shell Charcoal Machine

Features at a Glance

Shuliy coconut shell charcoal making machine is a machine that can convert coconut shells into high calorific value coconut shell charcoal. A coconut shell charcoal machine with a charcoal briquette machine can help you to get many shapes of coconut shell charcoal. Compared with other brands of charcoal machines, our machine can effectively prevent wood tar from clogging the pipes.

Coconut shell charcoal is a popular type of charcoal that is known for its high carbon content, low ash content, and strong heat generation properties. It’s commonly used in various applications such as cooking, heating, and industrial processes.

The Benefits of Shuliy Coconut Shell Charcoal Machine

Efficient Carbonization: Shuliy coconut shell charcoal machine is designed to efficiently carbonize coconut shells, converting them into high-quality charcoal with high carbon content and minimal impurities.

Various Output Options: Shuliy coconut shell charcoal making machines often come with different output capacities, allowing you to choose the right machine based on your production needs, whether small-scale or large-scale.

Versatility in Shapes: Some of Shuliy coconut charcoal making machines offer the flexibility to produce charcoal in various shapes, such as briquettes, cuboid shapes, spheres, etc., catering to different market demands and applications.

Consistent Quality: The coconut shell charcoal machine is designed to ensure consistent quality in the final charcoal products, which is crucial for customer satisfaction and market acceptance.

Reliability and Durability: Shuliy coconut shell charcoal making machines are typically built with robust materials and construction, ensuring their longevity and reliability even under prolonged use.

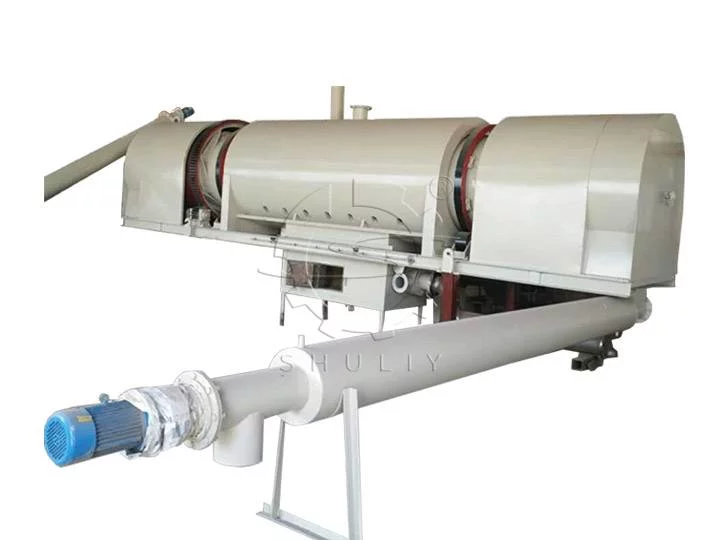

Different Types of Coconut Shell Charcoal Making Machines for Sale

There are three different types of coconut shell charcoal making machines for you to choose from: the hoisting type coconut shell charcoal making equipment, the continuous coconut shell charcoal machine, and the horizontal coconut shell charcoal making machine. If you’re looking to produce coconut shell charcoal on a large scale, we recommend using the continuous carbonization furnace. On the other hand, if you’re considering smaller-scale production, we recommend using the hoisting type carbonization furnace or the horizontal carbonization equipment.

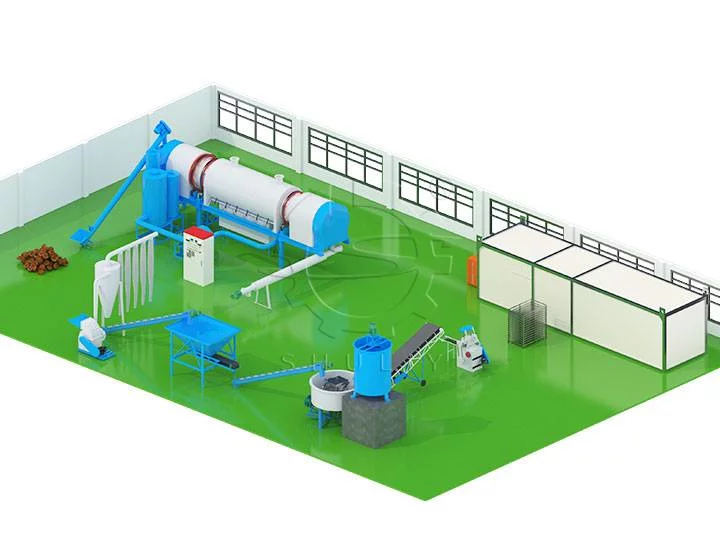

Complete Coconut Shell Charcoal Briquettes Making Process

The process of making coconut shell charcoal briquettes usually includes the following steps. In general, different steps require different coconut shell charcoal making machines.

Carbonization of Coconut Shells

First, the coconut shells need to go through a carbonization process, where they are heated at high temperatures and in a low-oxygen environment. This is the most important coconut shell charcoal making machine. This removes the moisture and volatile components leaving behind char with a high carbon content. This can be done through a coir carbonization furnace or other type of carbonization equipment.

Coconut Shell Charcoal Crushing

The carbonized coconut shell charcoal is crushed into a powder to help increase the surface area of the charcoal and improve the efficiency of the subsequent mixing and molding process. This step is usually accomplished using a charcoal crushing machine.

Mixing

The carbonized coconut shell charcoal powder needs to be mixed with appropriate proportions of water and binder. The water and binder help to hold the charcoal powder together and maintain its shape after briquetting.

Molding/Briquetting

The mixed charcoal powder is placed in a coconut shell charcoal briquetting machine. The coconut shell briquette machine applies pressure to compress the coconut shell charcoal powder into lumps. These lumps of charcoal powder are known as charcoal briquettes or charcoal barbecue briquettes.

Drying

The formed charcoal briquettes need to be dried to remove the moisture from them. This ensures the stability and quality of coconut shell charcoal briquettes.

Coconut Shell Charcoal with Different Shapes

You can create coconut shell charcoal in various shapes, such as coconut shell charcoal briquettes, coconut shell charcoal balls, coconut honeycomb coal, coconut shell charcoal for hookah/shisha, and coconut shell charcoal barbecue briquettes. Different shapes of coconut shell charcoal can be produced by using different types of coconut shell briquette machines. It’s important to note that if you want to create the shapes mentioned above, you’ll need to first crush the carbonized coconut shell into charcoal powder. This is where a charcoal crushing machine comes into play.

By utilizing different coconut shell briquette machines and preparing the charcoal in powdered form, you can achieve a variety of shapes for your coconut shell charcoal products. This versatility allows you to cater to different markets and applications, whether it’s for barbecue, smoking, or industrial purposes.

Application of Coconut Shell Charcoal

BBQ Fuel: Coconut shell charcoal is one of the ideal fuels for barbecues. The high heat and low ash content it produces when burned makes it a popular choice for outdoor grilling, field cooking, and home kitchens.

Home Heating: Coconut shell charcoal made by a coconut shell charcoal making machine can be used as a heating fuel. It is especially good for fireplaces, fireplaces, and stoves. It releases heat continuously to maintain a warm environment.

Industrial Use: Coconut shell charcoal is also widely used in some industrial fields. Because of its high-temperature heat production and adsorption capacity, it can be used in processes such as metal smelting, water treatment, and gas purification.

Pharmaceutical and Cosmetic Manufacturing: Coconut shell carbon is used as a raw material for pharmaceutical and cosmetic manufacturing. It is commonly used in the manufacture of activated carbon for use in drug detoxification, skin cleansing, and beauty products.

Environmental Programs: Coconut shell charcoal has some applications in the environmental field. Many customers use coconut shell charcoal as a soil conditioner and sewage treatment agent. It improves soil structure, enhances water treatment, and helps environmental protection.

Shisha/Hookah: Coconut shell charcoal made by coconut shell charcoal making machine usually has a low ash content, which means it produces relatively little ash during combustion. This helps to maintain the purity and taste of hookah.

Auxiliary Equipment for Making Coconut Shell Charcoal

When making coconut shell charcoal, various auxiliary coconut shell charcoal making machines can be used to improve the efficiency and quality of the coconut shell charcoal production process.

Coconut shell charcoal dryers: Coconut shells usually contain moisture, which needs to be removed before carbonization. Dryers such as rotary drum dryers can be used to reduce the moisture content of coconut shells to make them suitable for carbonization.

Charcoal Crusher: To make charcoal briquettes the carbonized coir needs to be crushed into smaller particles. A hammer charcoal crushing machine can be used for this purpose.

Charcoal Mixer: A charcoal mixer machine is needed to mix the coconut shell charcoal powder with a binder such as starch. The machine can evenly mix the charcoal powder and binder.

Coconut Shell Charcoal Packaging Machine: Once the charcoal is prepared, it needs to be packaged and ready for distribution. Coconut shell charcoal packaging machines help to simplify the packaging process.

How to Dry Coconut Shell Charcoal?

There are two options for drying coconut shell charcoal: using a charcoal dryer machine or natural drying.

When using a charcoal drying machine, spread the freshly made charcoal evenly on a pallet or in a storage box and place it in the dryer, set the appropriate temperature and time, the machine will gradually reduce the moisture content of the charcoal by circulating warm air, after finishing the drying, the charcoal will be drier and ready for further processing or packaging.

Whereas if you choose to dry naturally, spread the charcoal in a well-ventilated area, preferably outdoors, on a clean surface, turn the charcoal regularly to ensure even drying, and avoid exposure to direct sunlight as this can lead to cracking and uneven drying. Depending on weather conditions and moisture levels, natural drying can take anywhere from a few days to a few weeks.

Whichever method is chosen, ensuring that charcoal is properly dried is critical to maintaining its quality and preventing the growth of mold during storage.

How to Start a Coconut Shell Charcoal Business?

Market Research

Begin by researching the market demand for coconut shell charcoal in your target area. Identify potential customers, competitors, and trends to understand the feasibility of your business.

Business Plan

Develop a comprehensive business plan that outlines your business goals, target market, marketing strategies, production processes, financial projections, and more. This plan will serve as a roadmap for your business.

Legal Requirements

Register your business and obtain any necessary licenses and permits. Check with local authorities to ensure you comply with regulations related to charcoal production and business operations.

Location

Choose a suitable location for your production facility. Consider factors such as accessibility, proximity to raw materials (coconut shells), and transportation options.

Equipment and Machinery

Acquire the necessary coconut shell charcoal making machine for carbonization, crushing, briquetting, and other coconut charcoal production processes. Choose machinery that aligns with the scale of your business.

Raw Materials

Establish a steady supply of coconut shells for your production. This could involve building relationships with coconut processing plants or coconut farmers.

Production Process

Set up your coconut shell charcoal production processes, including carbonization, crushing, mixing, molding, and drying. Ensure that the processes are efficient and produce consistent quality charcoal.

Quality Control

Implement quality control measures to ensure that your coconut shell charcoal meets the required standards. Consistent quality will build trust among your customers.

Marketing and Sales

Create a marketing strategy to promote your coconut shell charcoal products. Utilize online and offline channels to reach potential customers. Attend trade shows, set up a website, and use social media for marketing.

Distribution

Establish distribution channels to get your products to customers. This could involve working with wholesalers, retailers, or directly selling to end consumers.

Financial Management

Manage your finances effectively by keeping track of expenses, revenue, and profits. Create a budget and monitor your cash flow.

How to Make Charcoal from Coconut Shell?

If you're looking to explore the world of sustainable energy…

What Is the Coconut Shell Charcoal Making Process?

Coconut shell charcoal has gained immense popularity due to its…

What Is Coconut Shell Charcoal Used For?

Coconut shell charcoal is a versatile and sustainable product that…

The Essence of a Strong Coconut Shell Charcoal Business Plan

In the world of sustainable ventures, a coconut shell charcoal…

Hot Product

Shisha Charcoal Machine for Making Hookah Charcoal

Shisha charcoal machine is specifically designed to compress…

Automatic Shrink Wrap Machine for Packing Charcoal Briquette

Automatic shrink wrap machine is a machine can…

Rotary Sawdust Dryer Machine | Sawdust Drying Machine

The rotary drum sawdust dryer machine is a…

Charcoal Grinder Machine for Crushing Charcoal into Powder

The charcoal grinder machine can grind large charcoal…

Coconut Shell Charcoal Making Machine for Turning Coconut Husk into Charcoal

We have three different types of coconut shell…

Continuous Carbonizing Machine for Rice Husk, Sawdust, Bamboo

Continuous carbonizing machine is a kind of equipment…

Comprehensive Crusher for Crushing Pallet, Wood Material

Comprehensive crusher is a machine capable of crushing…

Wood Shaving Machine for Animal Bedding

Wood shaving machine is a mechanical device designed…

Drum Wood Chipper for Making Wood Chips

Drum wood chipper is a specialized equipment used…