Drum Wood Chipper for Making Wood Chips

Commercial Wood Chipper for Sale

Drum Wood Chipper for Making Wood Chips

Commercial Wood Chipper for Sale

Features at a Glance

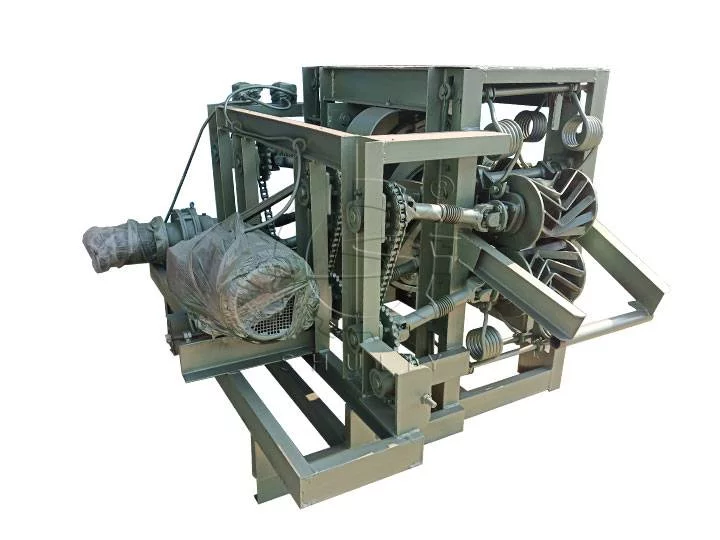

Drum wood chipper is a specialized piece of equipment used to process wood logs, branches, and other types of wood waste into smaller wood chips. It is commonly used in the forestry, woodworking, and biomass industries to efficiently convert raw wood materials into usable chips that can be further processed or used for various purposes. The best feature of this machine is its high output compared to other types of wood chippers.

The drum wood chipper operates by feeding wood materials into a rotating drum with sharp blades attached to its surface. As the drum spins, the blades cut and chip the wood into smaller pieces. The size and thickness of the wood chips can be adjusted by changing the speed of the drum or adjusting the position of the blades.

Advantages of Drum Wood Chipper

- Reliability and Quality: Shuliy is known for producing machinery with good build quality and reliability. Their drum wood chippers are likely to be designed and manufactured with attention to detail and sturdy materials, ensuring long-lasting performance.

- Safety Features: Our company incorporates safety features into our wood chippers, such as safety hoppers and emergency stop buttons, to prioritize user safety during operation.

- Customizable Screen Mesh. We can customize the screen mesh according to the customer’s size requirements for the finished product.

- Efficiency: Shuliy drum wood chips making machine is expected to be efficient in chipping wood materials. The design of the drum and the cutting mechanism could result in consistent and high-quality wood chips.

- Versatility: Depending on the model, Shuliy drum wood chippers might be capable of handling various types and sizes of wood materials, making them suitable for a range of applications.

Working Principle of Drum Wood Chipper Machine

- Feeding: Wood materials (such as logs, branches, etc.) are fed into the inlet of the drum wood chipper machine.

- Chipping: The wood materials are fed into the rotating drum. The drum’s surface is equipped with sharp blades. As the drum rotates, the blades come into contact with the wood and chip them.

- Chipping process: The wood materials pass through the blades on the drum, getting cut into smaller wood chips. These wood chips are discharged from the other side or the bottom of the drum.

- Adjusting chipping size: Depending on the requirements, the size and thickness of the produced wood chips can be changed by adjusting the drum’s speed or the position of the blades. Typically, the chipper has different settings to meet various wood chip size needs.

- Wood chip collection: The generated wood chips can be collected using a collection system for further processing or other purposes.

- Discharge: Apart from wood chips, there may also be some smaller wood particles and splinters. These are usually eliminated through screens or air streams to provide clean wood chip products.

What Is a Good Wood Chipping Machine?

The definition of a “good” wood chipping machine can vary depending on individual needs and preferences. However, there are some key features and factors to consider when determining what makes a wood chipping machine suitable for your specific requirements:

- Power and Capacity: A good wood chipping machine should have sufficient power and capacity to handle the types and sizes of wood materials you intend to chip. Consider the engine horsepower or electric motor power and the maximum diameter of branches the chipper can handle.

- Chipping Mechanism: The chipping mechanism, such as a drum or disc, should be robust and efficient in producing consistent and high-quality wood chips. Drum wood chippers are known for producing uniform chips, while disc chippers might offer better efficiency in some cases.

- Durability and Build Quality: A good wood chipper should be built with sturdy materials and components, ensuring long-term durability and reliability, even under heavy usage.

How Much Is a Drum Chipper?

The cost of a drum chipper can vary widely depending on factors such as the brand, model, size, features, and where you purchase it. Generally, drum chippers range in price from a few hundred dollars for smaller, basic models designed for residential use, to several thousand dollars for larger, commercial-grade machines with advanced features.

Residential/Consumer-grade drum chippers: These are smaller, more compact chippers suitable for occasional use in home gardens or small-scale landscaping. Prices can start from around $200 to $800.

Commercial/Industrial-grade drum chippers: These heavy-duty machines are designed for professional use and can handle significant quantities of wood. Prices for commercial-grade chippers can range from $2,500 to $10,000 or more, depending on their capacity and features.

Drum Wood Chipper for Sale

Two hot-selling drum wood chippers are for sale, please feel free to contact us if you need them.

| Model | SL-218 | SL-216 |

| Knife Quantity | 2 | 2 |

| Feeding size | 300*680 mm | 230*500 mm |

| Capacity | 10-15 t/h | 5-8t/h |

| Raw material dimension | ≤300 mm | ≤230 mm |

| Wood chip size | 25 mm(Adjustable) | 25 mm(Adjustable) |

| Main power | 110 kw | 55 kw |

| Weight | 8600 kg | 5600 kg |

| Feeding inlet conveyor | 6 m | 6 m |

| Outlet conveyor | 8 m | 8 m |

| Packing Size | 3105*2300*1650 mm | 2735*2200*1200 mm |

Why Use a Wood Log Chipper Machine?

- Wood Waste Management: Wood log chipper machines are excellent tools for managing wood waste. They can efficiently process tree branches, logs, and other wood materials, reducing them to smaller wood chips or sawdust. This makes it easier to handle and transport the wood waste for disposal or recycling.

- Mulching and Landscaping: Wood chips produced by a drum wood log chipper machine can be used as mulch in gardens, landscaping, and around plants. Mulch helps retain moisture, suppresses weed growth, and adds nutrients to the soil as it decomposes.

- Composting: Wood chips can be added to compost piles to improve aeration and provide a source of carbon for the composting process. This helps accelerate the decomposition of organic matter and results in nutrient-rich compost.

- Biomass Energy Production: Wood chips are a valuable source of biomass energy. They can be used as a renewable fuel source in biomass power plants or converted into wood pellets or briquettes for use in stoves and boilers.

- Erosion Control: Wood chips can be used in erosion control efforts to stabilize soil and prevent soil erosion in landscaping projects.

Can a Wood Drum Chipper Make Sawdust?

Yes, a wood drum chipper can produce sawdust as a byproduct during the wood chipping process. Sawdust is a result of the wood being cut or shredded by the blades or knives in the wood drum chipper.

The size and texture of the sawdust produced by the wood drum chipper can vary depending on the design and settings of the machine. Some drum wood chippers are specifically designed to produce smaller wood chips, which can resemble sawdust, while others may generate larger wood chips or chunks.

If you need fine sawdust for specific applications, such as woodworking, animal bedding, or fuel pellets production, you may need to use a wood shaving machine.

Disc Wood Chipper for Log Chips Production

Disc wood chipper is a type of machine used in…

Hot Product

Charcoal Briquettes Dryer for Charcoal Drying

The Shuliy charcoal briquettes dryer is a hot…

Double Roller Wood Debarker Machine for Wood Processing

Double roller wood debarker machine can handle various…

Coconut Shell Charcoal Making Machine for Turning Coconut Husk into Charcoal

We have three different types of coconut shell…

Shisha Charcoal Packing Machine

Shisha charcoal packing machine has efficient packaging speed…

Hoisting Carbonizer Machine

Hoisting carbonizer machine is a equipment make charcoal…

Disc Wood Chipper for Log Chips Production

Disc wood chipper is a type of machine…

Charcoal Grinder Machine for Crushing Charcoal into Powder

The charcoal grinder machine can grind large charcoal…

Vertical Log Peeling Machine

Vertical log peeling machine is specifically designed to…

Comprehensive Crusher for Crushing Pallet, Wood Material

Comprehensive crusher is a machine capable of crushing…