Carbonization Furnace for Charcoal Making

Carbonizing Machine | Carbonization Stove

Carbonization Furnace for Charcoal Making

Carbonizing Machine | Carbonization Stove

Features at a Glance

Shuliy carbonization furnace is used to convert raw materials such as wood, rice husk, and coconut shells into biomass raw materials by using high-temperature carbonization and low-temperature carbonization. Our unique flue gas filtration system and de-dusting system can effectively filter wood tar and prevent pipe clogging.

What Are the Types of Carbonization Furnaces?

Carbonization furnaces come in various types, each with its unique design and functionality. The three main types of carbonization furnaces are:

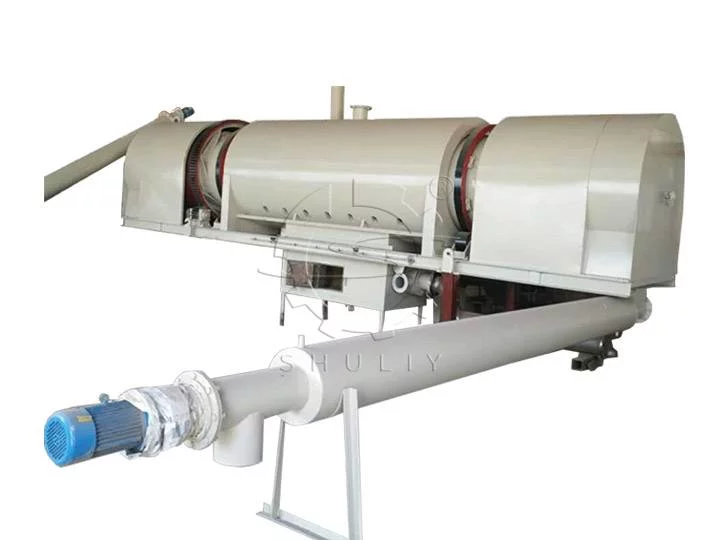

Horizontal Carbonizing Machine

The horizontal carbonizing machine features a horizontal structure that allows for efficient loading and unloading of materials. It operates by heating the organic matter in a controlled oxygen-deficient environment, resulting in the conversion of the material into charcoal. This type of furnace is widely used for its simplicity and ease of operation.

Hoisting Type Carbonization Stove

The hoisting-type carbonization stove utilizes a vertical design where the raw material is loaded from the top and gradually descends as the carbonization process takes place. This type of furnace offers advantages such as enhanced heat distribution and increased production capacity. It is commonly employed for large-scale charcoal production.

Continuous Carbonization Stove

The continuous carbonization furnace is designed for uninterrupted and automated carbonization processes. It consists of a conveyor system that continuously feeds the organic material into the furnace, allowing for a continuous and efficient production of charcoal. This type of furnace is ideal for high-volume charcoal production and industrial applications.

How Does Carbonization Furnace Work?

The working principle of the carbonization furnace is to control the temperature and atmosphere in a sealed combustion chamber to decompose the raw materials at high temperatures. In an oxygen-deficient or low-oxygen environment, the moisture and volatile substances in the raw materials are released. The remaining carbonaceous substances are converted into charcoal. This process is commonly known as charring or retorting.

The Use of Carbonizing Machine

Carbonization furnaces are widely used in various charcoal briquette production lines. The produced charcoal is utilized for purposes such as:

- Fuel: Charcoal is widely used as a clean-burning fuel in households, restaurants, and industrial settings for cooking, heating, and energy generation.

- Metallurgy: Charcoal plays a vital role in the metallurgical industry, particularly in the production of iron and steel, as a reducing agent and heat source.

- Agriculture: Charcoal is used in agricultural practices as a soil amendment to improve soil fertility, moisture retention, and nutrient availability.

- Activated Carbon: Certain carbonization furnaces are specifically designed for the production of activated carbon, which finds applications in water purification, air filtration, and various industrial processes.

- Chemical Industry: Charcoal serves as a precursor for the production of chemicals such as activated carbon, carbon black, and many organic compounds.

What Are the Benefits of Carbonization?

- Renewable Energy: The use of charcoal produced from carbonization helps reduce reliance on non-renewable fossil fuels, providing a sustainable energy alternative.

- Waste Management: Carbonization furnaces contribute to waste management by converting organic waste into a valuable and usable product.

- Environmental Friendliness: The carbonization process reduces the emission of greenhouse gases and harmful pollutants, making it an environmentally friendly method of fuel production.

- Economic Opportunities: Carbonization furnaces create economic opportunities by promoting the production of charcoal for various industries and applications, thereby supporting local economies and job creation.

How Hot Can a Charcoal Furnace Get?

Charcoal furnaces can reach temperatures ranging from 700 to 1,200 degrees Celsius (1,292 to 2,192 degrees Fahrenheit), depending on the design, fuel type, and operational conditions. These high temperatures are crucial for driving off moisture and volatile components during the carbonization process, resulting in the production of high-quality charcoal.

What Is the Purpose of the Carbonization Process?

The carbonization process serves the purpose of transforming organic materials, such as wood, plant residues, or biomass, into charcoal. During carbonization, the organic matter is heated in a controlled environment with a limited oxygen supply. This controlled heating process drives off moisture, volatile components, and impurities, leaving behind a carbon-rich substance known as charcoal. The resulting charcoal possesses high carbon content and is widely used as a fuel source, in industrial processes, and for various other applications.

Carbonization furnaces are indispensable in the production of charcoal from organic materials. The carbonization process offers numerous benefits, such as renewable energy production, waste management, environmental friendliness, and economic opportunities. These furnaces operate at high temperatures, enabling the conversion of organic matter into charcoal while minimizing carbon dioxide emissions. Shuliy Charcoal Machinery is a professional carbonization furnace manufacturer, if you need this machine, please feel free to contact us.

Horizontal Charcoal Furnace

Shuliy horizontal charcoal furnace is an ideal choice for charcoal…

What Happens During Carbonization?

Carbonization is a fascinating process that involves the conversion of…

Hoisting Carbonizer Machine

Hoisting carbonizer machine refers to a carbonization furnace that incorporates…

Continuous Carbonizing Machine for Rice Husk, Sawdust, Bamboo

Shuliy continuous carbonizing machine is a kind of equipment used…

Advantages and Disadvantages of Different Carbonization Furnaces Designs

Carbonization furnaces are used to convert wood into charcoal. There…

How to Choose a Biochar Carbonization Furnace?

Carbonization is a process of converting organic materials into carbon…

How Does Wood Turn to Charcoal?

Wood, a renewable resource, can be transformed into charcoal through…

Hot Product

Animal Feed Pellet Machine

Animal feed pellet machine can be used in…

Sawdust Briquette Machine for Making Pini Kay Briquettes

The briquettes produced by the Shuliy machine have…

BBQ Charcoal Briquettes Machine

By changing molds, our BBQ charcoal briquettes machine…

Carbonization Furnace for Charcoal Making

Three different types of carbonization furnaces are used…

Disc Saw for Wood Cutting

Shuliy's disc saw machine can handle many types…

Horizontal Charcoal Furnace

Discover our efficient, eco-friendly horizontal charcoal furnace. Perfect…

Efficient Compressed Wood Pallet Machine for Sale

Shuliy's compressed wood pallet machine is equipped with…

Charcoal Briquette Machine for Bio Coal Briquettes Making

Charcoal briquette machine is a equipment designed to…

Horizontal Band Saw Mill

Horizontal band saw mill is a type of…