Should You Remove Bark Before Drying Wood?

When it comes to drying wood, the question of whether to remove the bark is one that often arises among woodworking enthusiasts and professionals. The decision holds significance as it can impact the quality of the wood, the efficiency of the drying process, and the final product’s overall appearance. This article delves into the considerations around removing bark before drying wood and also discusses the role of a log peeling machine in this context.

The Importance of Bark Removal

Bark serves as a protective layer for trees, shielding them from environmental factors and pests. However, when it comes to preparing wood for drying, removing the bark offers several advantages. Let’s explore some key reasons why bark removal is often recommended:

- Uniform Drying: Bark can act as a barrier, slowing down the moisture evaporation process during drying. This can lead to uneven drying, which in turn might result in warping, cracking, or other defects. By removing the bark, wood dries more uniformly and reduces the risk of structural issues.

- Preventing Mold and Insects: Bark tends to trap moisture, creating an environment conducive to mold and fungi growth. Moreover, bark can provide shelter and sustenance for insects, potentially leading to infestations. Removing the bark reduces the chances of these problems occurring during the drying process.

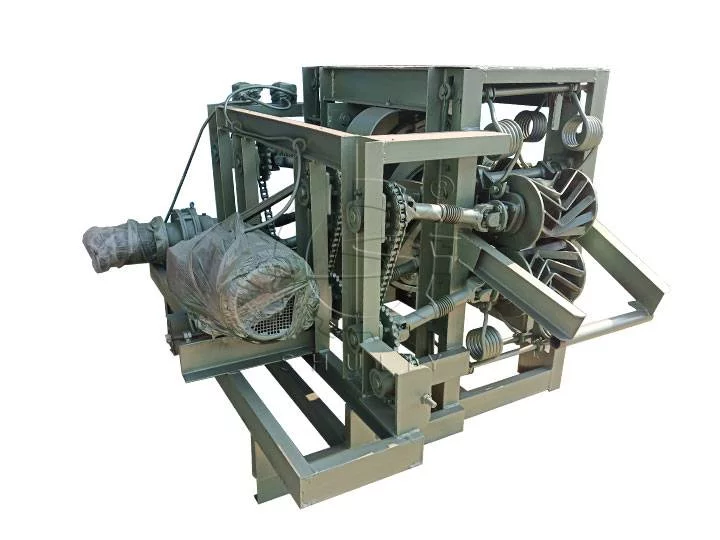

- Efficiency and Speed: A log peeler machine, such as the advanced models available today, can streamline the process of removing bark. This not only saves time but also ensures efficient and consistent results. The log peeler machine can efficiently strip away the bark, preparing the wood for the drying process.

The Role of a Log Peeler Machine

In modern woodworking practices, a log peeler machine has become an invaluable tool. This specialized equipment is designed to efficiently and effectively remove bark from logs. The machine utilizes various mechanisms to achieve bark removal while minimizing damage to the underlying wood. This is particularly beneficial for large-scale wood processing where manual bark removal might be time-consuming and labor-intensive.

Benefits of Log Peeler Machine

- Precision: Log peeler machines are engineered to ensure precise bark removal. This precision contributes to consistent wood quality and optimal drying outcomes.

- Time and Labor Savings: The mechanized process of bark removal significantly reduces the time and labor required. This is especially advantageous for commercial woodworking operations.

- Reduced Waste: Log peeler machines minimize the amount of wood wasted during the bark removal process. This contributes to cost savings and environmental sustainability.

In the realm of wood drying, the decision to remove bark holds implications for the final product’s quality and appearance. While bark removal is generally recommended for efficient and uniform drying, the advent of log peeler machines has revolutionized this process. These machines play a crucial role in simplifying and enhancing the bark removal process, ultimately leading to better wood drying results. Whether you are a woodworking hobbyist or a professional, understanding the role of bark removal and log peeler machines can help you achieve superior outcomes in your projects.