Charcoal Briquette Extruder Machine Exported to Guatemala

In June 2021, Shuliy Charcoal & Wood Machinery proudly dispatched a high-quality charcoal briquette extruder machine to Guatemala, marking a pivotal step in revolutionizing the local charcoal industry. This case study sheds light on the transformational journey undertaken by a dedicated customer who embraced innovation for a sustainable future.

The Client’s Background and Ambition

The recipient of the charcoal briquette machine was a seasoned entrepreneur deeply rooted in the charcoal trade. With a history of producing traditional hardwood charcoal, the client found themselves faced with a new challenge: surplus charcoal. Driven by an unwavering commitment to environmental responsibility, the client sought to repurpose these surplus resources and give them a new lease of life.

Empowering Sustainability through Technology

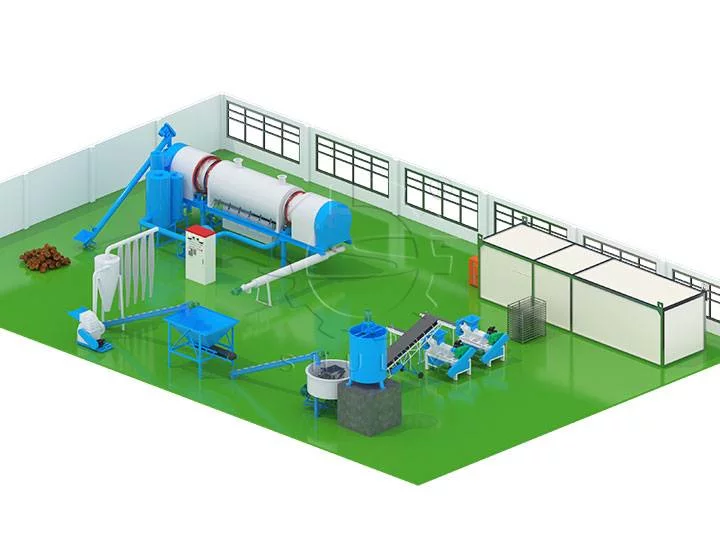

Recognizing the potential of our cutting-edge charcoal briquette extruder machine, the client approached Shuliy Charcoal & Wood Machinery with a clear vision. They aimed to convert their surplus charcoal into versatile charcoal briquettes of various shapes, catering to a diverse market demand. Our expert sales team provided invaluable guidance, revealing that the key to achieving this lay in the adaptability of our machinery.

A Tailored Approach to Transformation

Listening attentively to the client’s aspirations, our sales team explained how the charcoal briquette extruder machine could be customized through the simple process of mold replacement. This flexibility allowed the client to create charcoal briquettes in an array of shapes, sizes, and densities, aligning perfectly with their vision for diversification.

The client was presented with an extensive range of mold options, each carefully designed to cater to specific customer preferences. From cylindrical to hexagonal, and even custom shapes, the client was empowered to craft charcoal briquettes that not only conserved precious resources but also delighted their discerning customers.

Respecting Client Input

At Shuliy Wood&Charcoal Machinery, collaboration is at the heart of every project. Recognizing the unique insights and experience that the client brought to the table, we ensured that their input was not only welcomed but actively integrated into the design and execution process. This collaborative spirit enriched the project, resulting in a customized solution that seamlessly merged the client’s expertise with our technological innovation.

Results: A Sustainable Success Story

With the acquired charcoal briquette extruder machine, the client transitioned from a surplus dilemma to a sustainable success story. They successfully converted their surplus hardwood charcoal into an array of high-quality charcoal briquettes that met and exceeded market expectations. This transformation not only contributed to reduced waste but also positioned the client as a pioneer in environmentally conscious business practices.

| Item | Specifications |

| Charcoal briquette machine | Model: SL-140 Power: 11kw Capacity: 500kg/h Weight: 850kg Dimension: 2050*900*1250mm Shape: hexagon (function: produce different shapes of charcoal briquette) |

| Mold | Shape:squareSize:2.5*2.5cm |

| Mold | Size:4*4cm |

| Hob plus conveyor | Function: crush charcoal into small charcoal. The size of the small square shape charcoal is 4*4*4cm |

| Wheel grinder machine | Model:1300 Power: 5.5kw Inner diameter: 1300mm Capacity: 500kg per hour Dimension: 135013501400mm Weight: 570kg |

The partnership between Shuliy Charcoal & Wood Machinery and our Guatemalan client showcased the transformative potential of technology in advancing sustainability goals. This case study highlights how innovation, when coupled with customer-centricity, can empower businesses to evolve, excel, and contribute positively to the environment.

As we move forward, Shuliy Charcoal & Wood Machinery remains committed to providing high-quality solutions that empower businesses to make sustainable choices and embrace a greener future.