Charcoal Mixer Machine for Mixing Charcoal Powder, Water and Binder

Charcoal Mixing Machine | Wheel Grinding Charcoal Mixer

Charcoal Mixer Machine for Mixing Charcoal Powder, Water and Binder

Charcoal Mixing Machine | Wheel Grinding Charcoal Mixer

Features at a Glance

The charcoal mixer machine is designed to blend and mix various materials used in charcoal production processes. It involves mechanisms such as rolling, compressing, squeezing, and friction to ensure a thorough and uniform mixture of components like charcoal powder, binders, water, and other additives.

Why Choose Shuliy Charcoal Mixing Machine?

- Uniform Mixing: The primary function of a charcoal mixer machine is to ensure the uniform mixing of charcoal dust, binders, and water. It uses mechanical forces like rolling, compressing, squeezing, and friction to achieve a thorough blend, resulting in a consistent mixture.

- Precise Blending Ratios: Charcoal mixer machines are designed to accurately control the blending ratios of charcoal dust, binders, and water. This precision ensures that the final mixture meets specific requirements and desired characteristics.

- Short Mixing Time: Charcoal mixing machines can complete the mixing process relatively quickly, typically within around 20 minutes. This short mixing time enhances production efficiency and throughput.

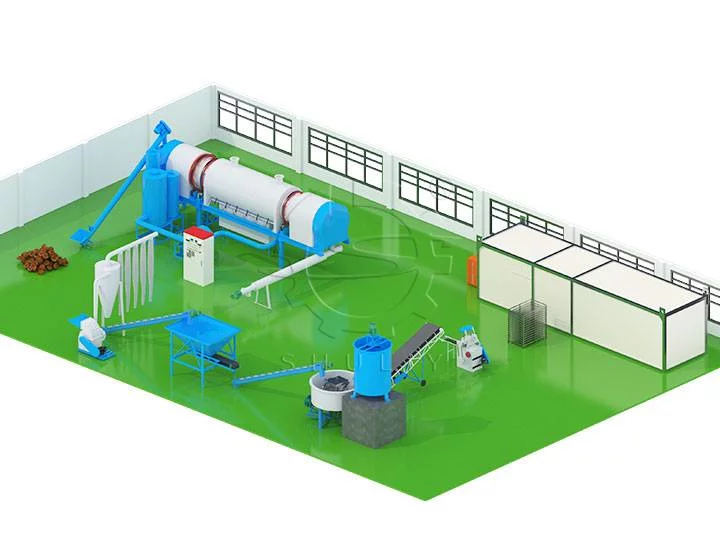

- Versatility in Application: These machines are versatile and can be used in various charcoal production lines, including waterpipe (hookah) charcoal, barbecue charcoal, coal rod, and honeycomb coal production.

- Options for Capacity: Charcoal mixing machines come in different sizes and capacities to suit the production needs of various scales, from small-scale operations to large industrial setups.

Working Principle of Charcoal Mixer Machine

At the heart of every successful charcoal production lies the ingenious mechanism of the charcoal mixer machine. This engineering marvel harnesses a symphony of mechanical forces – rolling, compressing, squeezing, and friction – to orchestrate the perfect blending of charcoal constituents. Charcoal dust, binders, and water intermingle in a harmonious dance, culminating in a homogeneous mixture that is the bedrock of high-quality charcoal products.

Remarkably, this meticulous process, typically completed within around 20 minutes, ensures an even distribution of materials, fostering consistency throughout the final product.

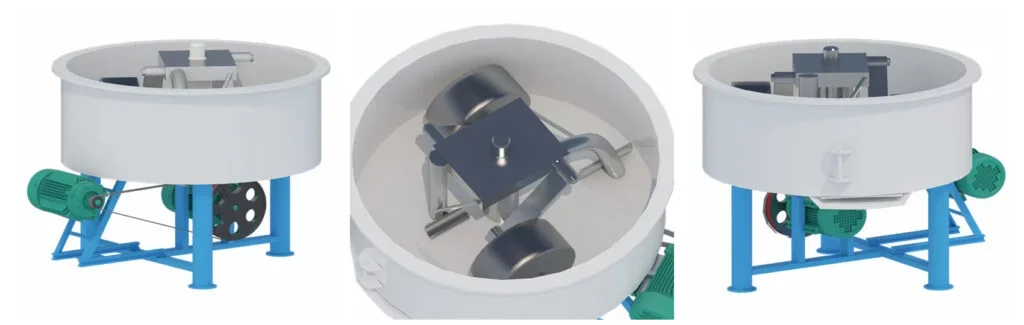

Structure of Charcoal Powder Blending Machine

- Drum: The drum is one of the core components of a charcoal powder blending machine. It is a cylindrical container that holds the charcoal dust, binder, and water for the mixing process. The drum is made of wear and corrosion-resistant materials to ensure long-term stability and reliability.

- Disc: The disc is the component that works in conjunction with the drum to promote a more uniform distribution of the mixture by rotating in coordination with the drum. It helps to intensify the mechanical action of the mixing process, thus achieving a complete mixing of the material.

- Squeegee: The squeegee is a component located inside the drum that is used to scrape the material off the drum surface. This ensures that the material is fully mixed. It helps to avoid buildup and agglomeration of the mixture.

- Reduction Gear: The reduction gear is a device that converts the power supplied by the motor into the appropriate speed and torque required by the drum and other moving parts. It serves to control and regulate the speed at which the machine operates.

- Motor: The motor is the power source that drives the charcoal powder blending machine. It provides the required rotational force to the other components to enable the mixing process to take place.

- Valves: Valves are used to control the entry and exit of the mixture. The inlet valve is used to introduce the raw material into the drum, while the outlet valve is used to discharge the mixture from the drum.

These major components working in tandem ensure that the charcoal mixer can efficiently mix the charcoal dust, binder, and water to produce a homogeneous mixture.

Technical Parameters of the Wheel Grinding Charcoal Mixer

| Model | Capacity(t/h) | Power(KW) | Disc diameter(mm) | Spindle speed(r/min) | Weight |

| SL-1000 | 1.5-2.5 | 5.5 | 1000 | 41 | 1 |

| SL-1200 | 1.5-3 | 7.5 | 1200 | 41 | 1.2 |

| SL-1500 | 7 | 15 | 1500 | 37 | 2 |

| SL-1600 | 9 | 18.5 | 1600 | 37 | 2.5 |

As you can see from the picture, we sell many models of charcoal mixer machines. Besides these machines, we also have other wheel grinding charcoal mixers with different outputs for sale. In addition, we can also provide customized service according to different customers’ needs. Therefore, if you need this charcoal mixer machine, please feel free to contact us.

Application of Coal Mixer Machine

The versatility of the coal mixer machine transcends industrial sectors. From the avid griller seeking charcoal perfection for weekend cookouts to industrial giants engaged in large-scale production of charcoal-based items, this machine serves as the linchpin of the production process. It finds its home in hookah charcoal production lines, barbecue charcoal processing lines, charcoal briquette production, and even honeycomb coal manufacturing. Whether at a micro or macro scale, the objective remains resolute: crafting charcoal products that are uniformly mixed and possess the desired attributes.

What Is the Price of a Charcoal Mixer Machine?

To be honest, the price of a charcoal mixer machine depends on a lot of factors, such as output, model, distance, machine quality, and so on. Therefore, if you want to know the exact price of this machine, please contact us first. Then tell us your production requirement and the nearest port to you. Then our sales will give you a detailed quotation. So, what are you waiting for, contact us as soon as possible.

Hot Product

Honeycomb Charcoal Briquette Machine for Making Honercomb

Honeycomb charcoal briquette machine, also known as a…

Shisha Charcoal Packing Machine

Shisha charcoal packing machine has efficient packaging speed…

Charcoal Briquette Machine for Bio Coal Briquettes Making

Charcoal briquette machine is a equipment designed to…

Wood Block Machine | Block Pallet Machine

Wood block machine is a machine that turns…

Charcoal Grinder Machine for Crushing Charcoal into Powder

The charcoal grinder machine can grind large charcoal…

Disc Saw for Wood Cutting

Shuliy's disc saw machine can handle many types…

Disc Wood Chipper for Log Chips Production

Disc wood chipper is a type of machine…

Drum Wood Chipper for Making Wood Chips

Drum wood chipper is a specialized equipment used…

BBQ Charcoal Packing Machine | Quantitative Packing Machine

BBQ charcoal packing machines are specialized equipment designed…