Hoisting Carbonizer Machine

Charcoal Carbonization Furnace | Carbonisation Furnace

Hoisting Carbonizer Machine

Charcoal Carbonization Furnace | Carbonisation Furnace

Features at a Glance

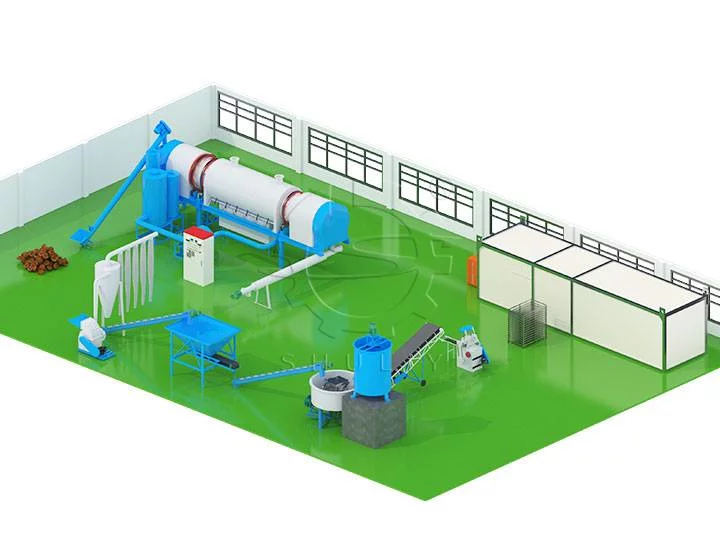

Hoisting carbonizer machine refers to a carbonization furnace that incorporates a hoisting mechanism to lift or move materials in and out of the furnace. This can be useful for automating the loading and unloading processes, improving efficiency, and ensuring worker safety by reducing manual handling.

The closed structure ensures uniform temperature during the carbonization process and a better carbonization effect. And the quality of carbonized products is higher.

Hoisting carbonizer machines are commonly used to convert carbonaceous materials such as wood, biomass, or coal into carbon-rich products such as charcoal or activated carbon. The process involves subjecting the material to high temperatures, known as pyrolysis, in an oxygen-free environment. This thermal decomposition evaporates the volatile components, leaving behind a carbon-rich residue.

The Advantages of Charcoal Carbonization Furnace

- Efficient Operation: The charcoal carbonization furnace enables the simultaneous operation of multiple units, allowing for enhanced productivity. Customers can choose to use one, two, three, or even more furnaces, depending on their production needs.

- Easy Installation and Mobility: Due to its modular design, the charcoal carbonization furnace can be easily assembled and disassembled, making it highly portable. This feature is particularly beneficial for industries that require frequent relocation or have limited space.

- Versatile Internal Liner: The furnace comes with interchangeable internal liners made of high-quality steel plates. Customers have the flexibility to alternate between three different liners, enabling them to adapt to various production requirements and optimize carbonization results.

- Smoke Purification System: The charcoal carbonization furnace is equipped with a state-of-the-art smoke purification system. This system effectively filters and purifies the exhaust gases produced during the carbonization process, minimizing environmental pollution and ensuring compliance with emission standards.

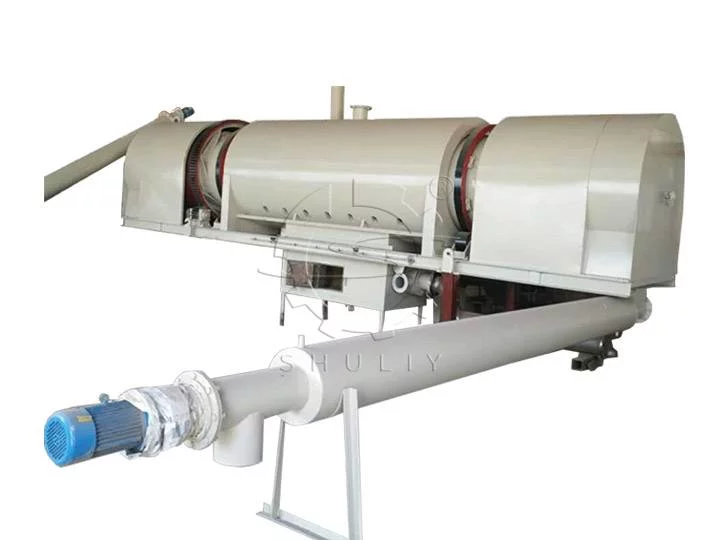

The Structure of the Hoisting Carbonizer machine

The hoisting carbonization machine features a unique combination structure that sets it apart from other types of carbonization furnaces. It is equipped with a remote-controlled lifting device, allowing operators to effortlessly handle loading and unloading tasks. The furnace comprises several key components, including the furnace body, furnace cover, heating chamber, exhaust pipe, inner liner, and outer shell.

Machine Parameters

| Model | SL-C1500 |

| Capacity | 2.5t-3t/d |

| Steel thickness | ≈6mm, customized |

| Machine weight | 2.8t |

| Carbonizing time once | 6-8 hours (vary to different raw materials and loading quantity) |

| Inner stove size | 1.5mx1.5m |

| Dimension | 1940x1900x1900mm |

The above is one of our regular suspended carbonization furnace. Its output is 2.5-3t/h. The thickness of the steel plate is 6mm. If you still want to know more about this machine, please feel free to contact us.

Other Types of Carbonizer Machines for Sale

Besides this machine, we also have a horizontal charcoal furnace and a continuous carbonizing machine for sale.

Working Principle of Hoisting Carbonizer Machine

The hoisting carbonizer machine uses waste wood or combustible materials at the bottom of the carbonization furnace to provide heat. Initially, the waste material is ignited and burnt in a large fire to provide heat until the temperature reaches 90°C. Then, the firepower decreases and enters the stage of warm fire combustion. At this time, the temperature is kept between 90°C and 150°C.

Once the temperature reaches 150°C, the dehumidification phase begins, which lasts about six hours while increasing the heat. When the temperature reaches 230°C, it enters the combustion-supporting stage and generates mixed gas. When the temperature reaches 280°C, it enters the stage of spontaneous combustion. At this time, the carbon monoxide gas produced by the carbonization furnace can be recycled, and there is no need to further burn wood to provide a heat source.

The door at the bottom of the stove can be optionally closed or opened throughout the combustion process. The furnace temperature can reach up to 500°C. To achieve the best carbonization effect, the carbonization furnace needs to burn for 14 hours, and the cooling time needs to be more than 10 hours. In addition, the pipe plays the role of gas circulation, combustion, and filtration. So the total burn time is 8-10 hours and the cooldown time is also 8-10 hours.

What Is the Use of Hoisting Carbonisation Furnace?

The carbonisation furnace finds extensive applications in industries such as charcoal production, wood processing, and biomass utilization. You can use this carbonization furnace to make coconut shell charcoal, bamboo charcoal, charcoal, and more! The furnace’s high-temperature environment facilitates the decomposition of these materials, converting them into high-quality charcoal with excellent combustion properties.

What Raw Materials Are Suitable for the Hoisting Carbonizer Machine?

The hoisting carbonization machine is compatible with a wide range of raw materials, making it a versatile choice for various industries. Some suitable materials include:

- Wood Logs: The furnace efficiently carbonizes wood logs, transforming them into charcoal used in industries such as metallurgy, chemical production, and agriculture.

- Bamboo: Bamboo is an abundant and renewable resource. The hoisting carbonization machine effectively converts bamboo into charcoal, which is highly valued for its hardness and long burning time.

- Coconut Shells: Coconut shells are commonly discarded as waste, but they can be transformed into valuable charcoal using the hoisting carbonization machine. Coconut shell charcoal is widely used in water purification, air filtration, and fuel applications.

- Agricultural Residues: The furnace can carbonize various agricultural residues, including rice husks, corn cobs, and sugarcane bagasse. This not only helps in waste management but also produces charcoal that can be used as a source of energy.

The hoisting carbonizer machine is a remarkable piece of equipment that offers efficient carbonization processes. Its unique structure, remote-controlled lifting device, interchangeable internal liners, and smoke purification system make it a reliable and environmentally friendly choice. Shuliy Charcoal Machinery is a professional charcoal machinery manufacturing company. We provide customers with various types of hoisting carbonizer machine. If you need it, please feel free to contact us.

Carbonization Furnace for Charcoal Making

Shuliy carbonization furnace is used to convert raw materials such…

Horizontal Charcoal Furnace

Shuliy horizontal charcoal furnace is an ideal choice for charcoal…

What Happens During Carbonization?

Carbonization is a fascinating process that involves the conversion of…

Continuous Carbonizing Machine for Rice Husk, Sawdust, Bamboo

Shuliy continuous carbonizing machine is a kind of equipment used…

Advantages and Disadvantages of Different Carbonization Furnaces Designs

Carbonization furnaces are used to convert wood into charcoal. There…

How to Choose a Biochar Carbonization Furnace?

Carbonization is a process of converting organic materials into carbon…

How Does Wood Turn to Charcoal?

Wood, a renewable resource, can be transformed into charcoal through…

Hot Product

Drum Wood Chipper for Making Wood Chips

Drum wood chipper is a specialized equipment used…

Hoisting Carbonizer Machine

Hoisting carbonizer machine is a equipment make charcoal…

Charcoal Mixer Machine for Mixing Charcoal Powder, Water and Binder

Charcoal mixer machine utilize mechanisms such as rolling,…

Sawdust Briquette Machine for Making Pini Kay Briquettes

The briquettes produced by the Shuliy machine have…

Charcoal Briquettes Dryer for Charcoal Drying

The Shuliy charcoal briquettes dryer is a hot…

Disc Wood Chipper for Log Chips Production

Disc wood chipper is a type of machine…

Shisha Charcoal Machine for Making Hookah Charcoal

Shisha charcoal machine is specifically designed to compress…

Efficient Compressed Wood Pallet Machine for Sale

Shuliy's compressed wood pallet machine is equipped with…

Honeycomb Charcoal Briquette Machine for Making Honercomb

Honeycomb charcoal briquette machine, also known as a…