How to Choose Suitable Wood Shredder Equipment for Biomass Charcoal Production?

With the increasing global emphasis on renewable energy, biomass charcoal is gaining attention as an environmentally friendly fuel. And in the whole production chain, the wood shredder is the key equipment that determines the raw material processing efficiency and charring effect.

Choosing a suitable wood shredder will not only save labour costs but also enhance the economic efficiency of the whole production line. So, in the face of the many types of wood crushers on the market, how do we choose suitable equipment for ourselves?

Define the type of material to be crushed

Different wood raw materials require different equipment. Common raw materials include:

- Logs, twigs, bark

- Wooden boards, wooden blocks, furniture waste

- Wood without nails

- Bamboo, palm shells, and other hard materials

Note: if the type of raw material is complex, the preference is for a comprehensive crusher with strong crushing capacity and nail removal function.

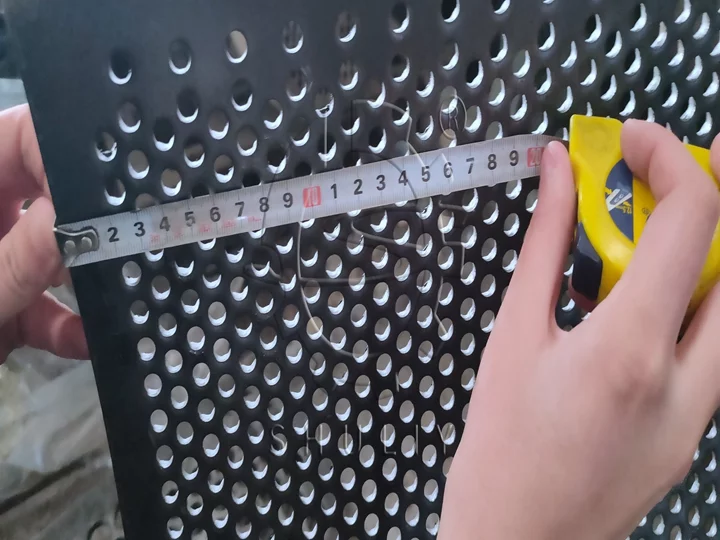

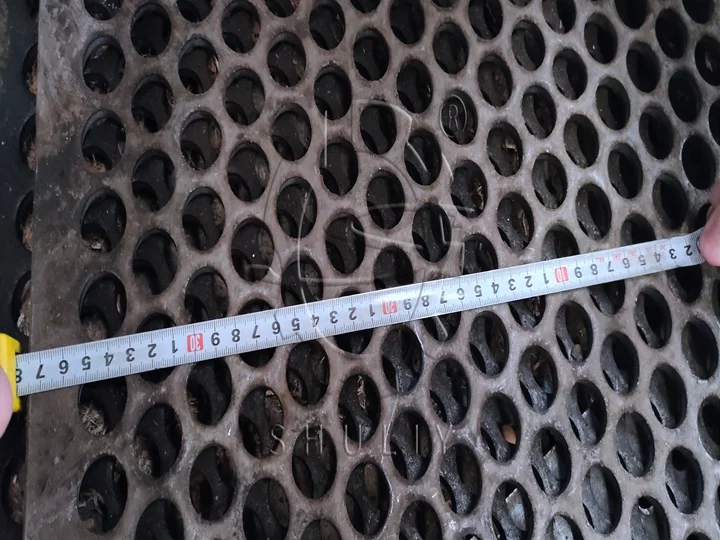

Match the equipment to the size of the material to be discharged

| Crush type | Particle size range | Applicable use |

| Primary crushing | 1–5 cm | Charcoal briquettes, charcoal powder |

| Fine crushing | 3–8 mm | Bars, mechanism charcoal |

| Ultrafine powder | <3 mm | Activated carbon and powder balling |

Wood chips used for carbonisation usually require a particle size between 3 and 8mm. Too coarse affects the rate of carbonisation, and too fine is not conducive to air circulation.

Generally, when the precision needs are less than 3mm, we recommend the mill even more.

Selection of equipment specifications according to capacity requirements

Match the wood crusher capacity to your size:

Small pulveriser

Hourly output: 600-800kg

Applicable scenes: home or small workshop

Medium-sized pulveriser

Hourly output: 1-3t

Applicable scenes: small-scale biomass charcoal plant

Large pulveriser

Hourly output: 5t and above

Applicable scenes: commercialised centralised production lines

Consideration of machine structure and ease of maintenance

Efficient production depends not only on high performance but also on stability and ease of maintenance.

- Removable screen for easy cleaning.

- Alloy hammer head or blade, wear-resistant.

- Equipped with an anti-jamming automatic shutdown protection device.

- With automatic feeding system can enhance the efficiency.

Note: when choosing, pay attention to the life of wearing parts, whether they are easy to replace, and whether the manufacturer provides after-sales service.

Examine the manufacturer’s strength and technical support

- Whether it supports voltage, frequency, and plug customisation.

- Whether it can provide CE, ISO, and other certificates.

- Whether can provide export packaging, test machine video, and a user manual.

- Whether there are Southeast Asia, Africa, and Europe customer case references.

Suggestion: Cooperate with experienced manufacturers; it is easier to land local projects with no worries after sales.

Shuliy wood shredder for sale

Choosing the right wood shredder for biomass charcoal production is the first step in improving the efficiency of raw material processing, ensuring charcoal quality, and reducing energy costs.

As a charcoal machine supplier for more than ten years, Shuliy has rich export experience and strong equipment manufacturing capacity.

If you want to get more professional selection advice, welcome to contact us. We provide:

- Raw material testing service

- Free trial video

- Customised solutions and quotations

- Overseas installation and technical guidance