Wood Crusher Machine for Biomass Waste

Wood Sawdust Machine | Timber Crusher Machine

Wood Crusher Machine for Biomass Waste

Wood Sawdust Machine | Timber Crusher Machine

Features at a Glance

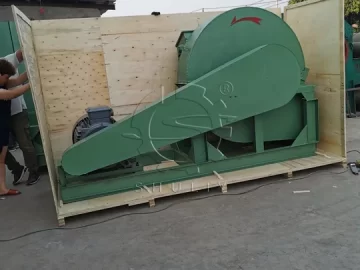

Wood crusher machine, also known as a wood shredder or wood sawdust machine, is a mechanical device used to reduce the size of wood materials into smaller pieces. Among the various options available, three notable types include the common wood crusher machine, the hammer mill wood crushing equipment, and the comprehensive crusher.

It is commonly used in the forestry industry, sawmills, and wood processing plants to process various types of wood waste, such as branches, logs, slabs, pallets, and tree stumps.

What Are the Advantages of the Shuliy Wood Shredder Machine?

Shuliy wood shredder offers numerous advantages for users in the forestry industry and wood processing plants. These include:

- High Efficiency: The Shuliy wood shredder is designed to deliver efficient and consistent performance, ensuring optimal productivity.

- Versatility: This wood sawdust machine can process a wide range of wood materials, including branches, logs, slabs, pallets, and tree stumps. It is also one of the main machines in the sawdust briquettes production line.

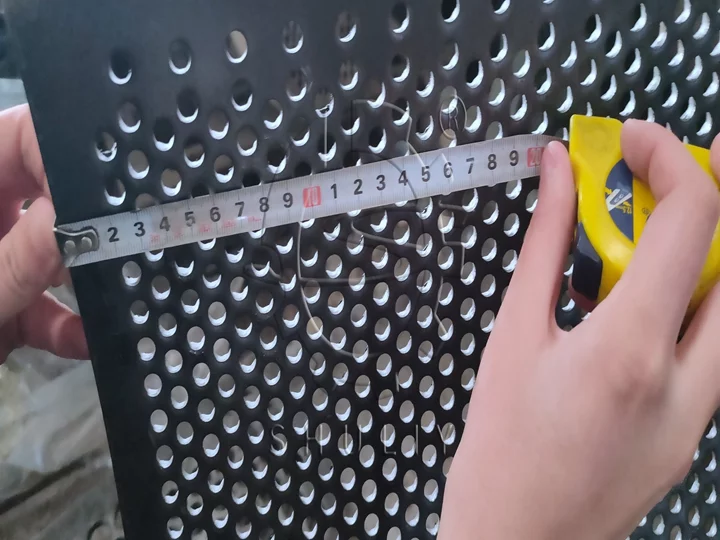

- Customizable Output: The machines allow users to adjust the size of the output, catering to specific requirements for different applications.

- User-Friendly Design: The Shuliy wood shredder machine is designed with user convenience in mind, offering ease of operation and maintenance.

- Robust Construction: Built with durable materials, these machines are known for their longevity and reliability, ensuring a prolonged service life.

The Size and Capacity of Timber Crusher Machine

The size and capacity of wood crusher machines vary depending on the specific model and intended use. Shuliy timber crusher machine is available in a range of sizes to accommodate different processing needs, from small-scale operations to large industrial-grade setups. The capacity of these timber crusher machines can range from a few hundred kilograms per hour to several tons, ensuring flexibility and scalability based on production requirements.

| Model | Capacity(kg/h) | Outlet size(cm) | Power(kw) |

| SL-420 | 600-800 | 0.3-0.8 | 7.5-11 |

| SL-500 | 1000-1500 | 0.3-0.8 | 18.5 |

| SL-600 | 1500-2000 | 0.3-0.8 | 30 |

| SL-700 | 2000-2500 | 0.3-0.8 | 37 |

| SL-900 | 2500-3000 | 0.3-0.8 | 55 |

| SL-1000 | 3000-4000 | 0.3-0.8 | 75+7.5 |

How Does a Wood Crusher Machine Work?

The wood crusher machine operates by feeding wood materials into a crushing chamber through a hopper. Within the chamber, rotating blades or hammers shred or crush the wood, resulting in smaller pieces. This process facilitates the subsequent utilization of wood waste for various purposes, such as biomass fuel production, composting, or as raw materials for wood-based products.

The Design of the Wood Crusher Machine

- Feeding Hopper: The wood sawdust machine includes a feeding hopper where the wood waste is loaded for processing. The hopper has a proper size and shape to facilitate easy and controlled feeding of the materials into the crushing chamber.

- Crushing Chamber: The crushing chamber houses the rotating blades or hammers responsible for shredding or crushing the wood. It is designed to maximize the contact between the wood waste and the blades, ensuring efficient and effective crushing.

- Blades: Depending on the machine type, there can be blades mounted on a rotating shaft inside the crushing chamber. These blades are designed to cut or pulverize the wood waste into smaller pieces. They are made from high-quality carbon steel materials to withstand impact and wear during the crushing process.

- Motor: The wood crushing equipment is powered by an electric motor. The motor is appropriately sized to provide sufficient power for the crushing operation. It has the character of being durable and energy-efficient to ensure reliable performance.

What Is the Price of Wood Sawdust Machine?

The cost of a wood crusher machine depends on several factors, including its size, capacity, features, and the specific supplier or manufacturer. Generally, larger and more powerful machines tend to have higher prices due to their advanced capabilities. Additionally, brand reputation and after-sales service can influence pricing. For accurate cost information, please contact Shuliy Charcoal Machinery Factory. We will recommend a suitable charcoal grinder for you according to your needs.

How to Choose a Suitable Biomass Wood Crusher Equipment?

Processing Requirements

Determine the type and volume of wood waste you need to process to ensure the machine’s capacity meets your production demands.

Size and Space Constraints

Consider the available space for the machine’s installation and operation, ensuring it fits within your facility.

Output Size

Assess the desired size of the wood chips or pieces for your intended application and select a machine that offers adjustable output capabilities.

Budget

Establish a budget and explore biomass wood crusher equipment that aligns with your financial constraints without compromising on quality and performance.

How to Use the Electric Log Crusher Machine Correctly?

To utilize a log crusher machine safely and effectively, follow these guidelines:

- Familiarize yourself with the machine’s user manual and operating instructions provided by the manufacturer.

- Ensure the log crusher machine is placed on a stable surface and connected to a reliable power source.

- Feed the wood waste into the hopper gradually, avoiding overloading the machine.

- Monitor the machine’s performance during operation and make any necessary adjustments to optimize efficiency.

- Regularly inspect the machine for wear and tear, and perform routine maintenance as recommended by the manufacturer.

What Are the Maintenance Requirements for Timber Shredder Machines?

To maintain the performance and prolong the lifespan of timber shredder machines, adhere to these maintenance practices:

- Regular Cleaning: Clean the machine’s components, including the feeding hopper, crushing chamber, and blades or hammers, to prevent material buildup and ensure consistent performance.

- Lubrication: Apply lubricating oil to the machine’s moving parts, such as bearings, gears, and shafts, as specified by the manufacturer to minimize friction and wear.

- Blade or Hammer Inspection: Periodically inspect the condition of the blades or hammers, and replace them if worn or damaged to maintain optimal cutting efficiency.

- Electrical Components: Check and test the electrical connections, switches, and safety features regularly to ensure proper functioning and prevent potential hazards.

- Professional Servicing: Schedule routine maintenance with authorized technicians to conduct comprehensive inspections, address any issues, and ensure overall machine reliability.

What Can Be Used for the Finished Product of the Wood Crushing Machine?

The finished products obtained from wood crushing machines have various applications, including:

- Biomass Fuel: The wood chips or wood sawdust can be used as a renewable energy source for heating or power generation in biomass boilers.

- Composting: The shredded wood waste is suitable for composting, contributing to organic soil enrichment in gardening or agricultural practices.

- Wood-Based Products: The processed wood materials can serve as raw materials for manufacturing particleboards, fiberboards, paper, and other wood-based products.

Wood crusher machines are versatile and efficient tools used in the forestry industry and wood processing plants. Shuliy wood crusher machines, including the log shredder machine, hammer blade log shredder machine, and integrated wood crusher machine, offer numerous advantages such as high efficiency, versatility, customizable output, user-friendly design, and robust construction. If you need a high quality wood crushing machine, please feel free to contact us.

Wood Hammer Mill Machine for Crushing Wood

Our wood hammer mill is a machine designed to pulverize…

Comprehensive Crusher for Crushing Pallet, Wood Material

The comprehensive crusher is a multifunctional industrial equipment specially used…

Hot Product

Double Roller Wood Debarker Machine for Wood Processing

Double roller wood debarker machine can handle various…

Wood Shaving Machine for Animal Bedding

Wood shaving machine is a mechanical device designed…

Disc Wood Chipper for Log Chips Production

Disc wood chipper is a type of machine…

Horizontal Charcoal Furnace

Discover our efficient, eco-friendly horizontal charcoal furnace. Perfect…

Animal Feed Pellet Machine

Animal feed pellet machine can be used in…

Coconut Shell Charcoal Making Machine for Turning Coconut Husk into Charcoal

We have three different types of coconut shell…

Vertical Bandsaw Mill for Wood Processing Plant

Vertical bandsaw mill is a type of sawmill…

Honeycomb Charcoal Briquette Machine for Making Honercomb

Honeycomb charcoal briquette machine, also known as a…

Efficient Compressed Wood Pallet Machine for Sale

Shuliy's compressed wood pallet machine is equipped with…