Charcoal Briquettes Dryer for Charcoal Drying

Charcoal Drying Machine | Charcoal Dryer

Charcoal Briquettes Dryer for Charcoal Drying

Charcoal Drying Machine | Charcoal Dryer

Features at a Glance

Shuliy charcoal briquettes dryer can reduce the moisture content of freshly made charcoal to about 5-10%. The exact dewatering effect depends on the initial moisture content of the charcoal, the operating temperature of the dryer, and the drying time. Our charcoal briquettes dryer allows you to easily control the drying temperature and time to precisely control the moisture content of the charcoal.

This is the last machine in the charcoal briquettes production line. The charcoal drying process is crucial for ensuring the briquettes have the right moisture content, as excess moisture can lead to difficulties in igniting and burning the briquettes effectively.

Advantages of Using a Charcoal Briquettes Dryer

- Improved Efficiency: The controlled hot air circulation ensures uniform drying, leading to a more efficient drying process and higher-quality charcoal briquettes.

- Time-Saving: Compared to traditional drying methods, the dryer significantly reduces the drying time, allowing for quicker production and faster turnaround.

- Versatility: The charcoal briquettes dryer can be used for a variety of charcoal-based products, including Honeycomb Coal, Shisha Charcoal, and BBQ Charcoal Briquettes, making it a versatile investment.

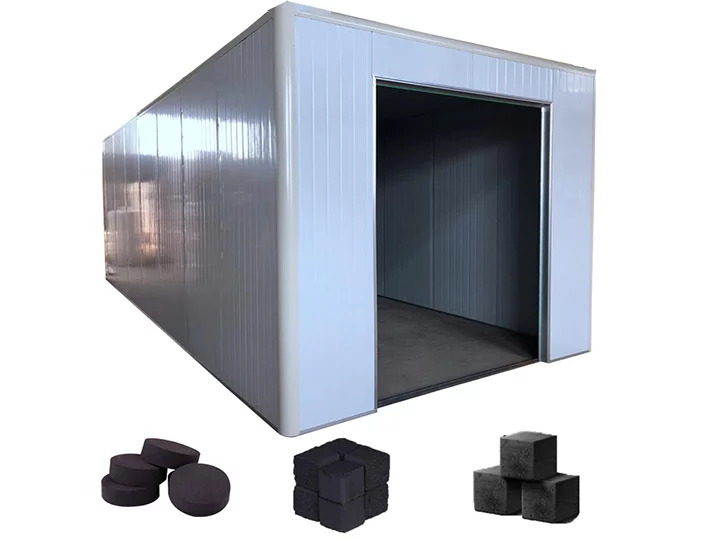

How Box Type Charcoal Briquettes Dryer Works?

Box type charcoal dryer machine is a common charcoal drying equipment. Its working principle is based on the principle of hot air circulation. Here is how the box charcoal dryer works:

- Drying room: The box-type charcoal dryer consists of a closed drying room. This room has a door for the user to put in and take out the charcoal to be dried.

- Trays: There are removable trays or racks in the drying room for the charcoal to be dried. These trays can be adjusted as needed, allowing the charcoal to be fully exposed to the hot air for even drying.

- Heating device: The box charcoal dryer is equipped with a heating device. This heating device generates hot air at a high temperature.

- Hot air circulation: The heating device will send high-temperature hot air into the drying room. The hot air will circulate in the room so that the heat is evenly distributed. This ensures that the charcoal is fully heated throughout the drying process.

- Control system: Box charcoal dryers are usually equipped with a control system for monitoring and adjusting parameters such as temperature, humidity, and time during the drying process. This ensures a stable and efficient coal drying process.

Box Type Charcoal Dryer Machine for Sale

| Model | SL-BD-08 | SL-BD-010 |

| Number of trays | 80pcs | 100pcs |

| Drying room size | 8m*2.3m*2.5m | 10m*2.3m*2.5m |

| Trolley | 8pcs | 10pcs |

| Circulating fan | 6pcs | 6pcs |

| Dehumidification fan | 2pcs | 2pcs |

Types of Charcoal Dryers

There are many types of charcoal dryers, here are a few common ones:

- Box charcoal dryer: The box type charcoal dryer is a common charcoal drying equipment. It has a closed drying room. The user can put the charcoal to be dried in a removable tray, and then push it into the drying room. The hot air circulation principle is used to speed up the charcoal drying process.

- Rotary charcoal Dryer: A rotary charcoal dryer is a device that dries charcoal by rotating a drum. The charcoal is put into the drum, and under the rotation of the drum, the hot air is in contact with the charcoal through the drum to make the charcoal dry quickly.

- Fluidized bed dryer: Fluidized bed dryer is a device that blows hot air into the drying chamber from the bottom to make the charcoal form a fluidized state in the bed to achieve drying.

- Microwave dryer: A microwave dryer is a device that uses microwave radiation to heat charcoal and evaporate moisture. It achieves fast and even drying results.

- Air Drying: While not a dryer, air drying is also a common method of drying charcoal. In the air drying process, it takes a long time for charcoal to be dried by natural wind.

The Importance of Proper Drying for Charcoal Briquettes

Proper drying of charcoal briquettes is crucial to ensure their performance and quality. Excess moisture can hinder ignition and combustion, leading to less efficient burning and decreased energy output. By using a charcoal briquettes dryer, manufacturers can guarantee that their products meet the desired specifications consistently.

How to Select the Right Charcoal Briquettes Dryer for Your Needs?

Understand your requirements

Determine the volume of charcoal briquettes you need to dry and the frequency of drying. Also, consider the specific drying parameters, such as temperature, drying time, and moisture content you need to achieve.

Consider the drying capacity

Look for a dryer with sufficient capacity to handle the amount of charcoal briquettes you produce. It should be able to handle both your current production level and any potential growth in the future.

Energy efficiency

Check the energy consumption of the charcoal briquettes dryer. Energy-efficient dryers will help you save on operational costs and reduce your environmental impact.

Drying time

Evaluate the drying time of different dryers. Shorter drying times can increase your production efficiency and reduce operational costs.

Quality of dried briquettes

Ensure that the dryer you choose can consistently produce high-quality dried charcoal briquettes without compromising their integrity or burning properties.

Applications of Charcoal Briquettes Dryer

The versatility of the charcoal briquettes dryer extends beyond charcoal briquettes alone. It can efficiently dry other charcoal-based products, such as Honeycomb Coal used in household heating and Shisha Charcoal for smoking enthusiasts. Additionally, BBQ Charcoal Briquettes, commonly used in outdoor grilling, can also benefit from the drying process, enhancing their performance.

Choose Shuliy Wood&Charcoal Machinery

Shuliy Wood&Charcoal Machinery is a reputable company with extensive experience in the production and manufacturing of wood and charcoal processing equipment. They offer a wide range of high-quality machines, including the advanced charcoal briquettes dryer, designed to meet the unique needs of their clients.

In addition, shuliy company also provides high-quality BBQ Charcoal Briquettes Machine, Charcoal Briquette Machine, Honeycomb Coal Briquette Machine, Shisha Charcoal Machine, and Carbonization Furnace. Please feel free to contact us if you need to.

The charcoal briquettes dryer is an indispensable tool for ensuring the efficiency, quality, and consistency of charcoal briquettes, as well as other related products. By incorporating cutting-edge technology, such as hot air circulation, it accelerates the drying process, saving time and energy.

For all your wood and charcoal machinery needs, contact Shuliy Wood&Charcoal Machinery today and experience the benefits of their top-notch products and excellent customer service.

Charcoal Dryer Exported to Libya

In September 2021, a significant advancement in the charcoal production…

Hot Product

Wood Crusher Machine for Biomass Waste

Wood crusher machine is a mechanical device used…

Charcoal Grinder Machine for Crushing Charcoal into Powder

The charcoal grinder machine can grind large charcoal…

Horizontal Charcoal Furnace

Discover our efficient, eco-friendly horizontal charcoal furnace. Perfect…

Double Roller Wood Debarker Machine for Wood Processing

Double roller wood debarker machine can handle various…

BBQ Charcoal Briquettes Machine

By changing molds, our BBQ charcoal briquettes machine…

Comprehensive Crusher for Crushing Pallet, Wood Material

Comprehensive crusher is a machine capable of crushing…

Animal Feed Pellet Machine

Animal feed pellet machine can be used in…

Disc Saw for Wood Cutting

Shuliy's disc saw machine can handle many types…

Charcoal Briquette Machine for Bio Coal Briquettes Making

Charcoal briquette machine is a equipment designed to…