Sawdust Briquette Machine for Sale in South Africa

In November 2021, a high-quality sawdust briquette machine embarked on a journey to South Africa. The purchaser of this remarkable machine was the owner of a prominent wood processing facility. Situated in the heart of South Africa, his wood processing factory was known for its consistent production of substantial amounts of wood chips and sawdust byproducts. Seeking innovative ways to minimize waste and maximize value, he decided to invest in a biomass briquette extruder from Shuliy Charcoal & Wood Machinery.

Why Do Customer Buy a Sawdust Briquette Machine?

The wood processing factory had been facing the challenge of dealing with an ever-increasing pile of wood chips and sawdust, which were generated as a result of their primary operations. Recognizing the untapped potential within these byproducts, the factory owner began researching sustainable solutions. This pursuit led him to Shuliy Charcoal & Wood Machinery, a reputable provider of high-quality briquette machines.

Parameter of the Sawdust Briquette Machine

| Model | SL-140 |

| Capacity | 250-300kg/h |

| Power | 18.5KW |

| Dimension | 1.56×0.65×1.62m |

| Voltage | 380v,590hz,3phase |

| Weight | 700 kg |

The Advantages of Saw dust Briquette Press

At Shuliy, the factory owner found not only a state-of-the-art saw dust briquette press but also a team of experts willing to guide him through the process. The decision to purchase the sawdust briquette machine was made with the dual purpose of reducing waste and generating an additional revenue stream. By converting the surplus sawdust into valuable briquettes, the factory owner aimed to contribute to a cleaner environment while simultaneously enhancing the financial health of his business.

The saw dust briquette press selected by the South African entrepreneur boasted cutting-edge technology, designed to efficiently compress sawdust into dense, burnable briquettes. The machine’s robust construction ensured durability, even when dealing with high volumes of material. The user-friendly interface and automated features of the machine made it a perfect fit for the wood processing facility’s needs.

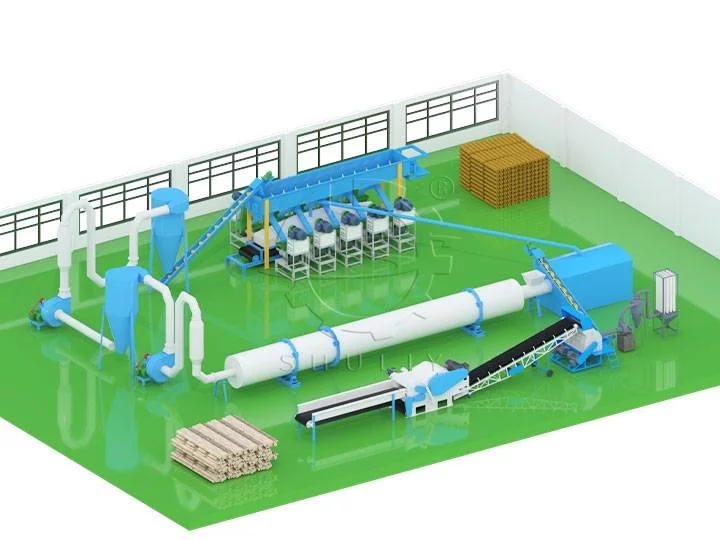

Upon the machine’s arrival, the wood processing facility underwent a transformation. The biomass briquette extruder was seamlessly integrated into the existing operations. The wood chips and sawdust that once posed a waste management challenge were now being fed into the machine’s hopper, where they were compressed under high pressure to form compact briquettes. These briquettes, with their enhanced energy density, emerged as an eco-friendly alternative to traditional fuels, such as coal or charcoal.

The benefits of this investment quickly became apparent. The factory owner not only reduced the environmental impact of his operations by repurposing waste but also diversified his product offerings. The briquettes found a receptive market as an efficient and sustainable heating source, appealing to both environmentally conscious consumers and industrial clients seeking cost-effective alternatives.

By aligning his business practices with sustainability and innovation, the wood processing factory owner showcased the potential for positive change within the industry. Through the sawdust briquette machine’s transformative power, he demonstrated that waste could be harnessed to create value, making a tangible contribution to both his bottom line and the environment.

A Reliable Biomass Briquettes Machine Manufacturer

Shuliy Charcoal & Wood Machinery’s dedication to providing high-quality machinery and comprehensive support played a pivotal role in the success of this South African case study. With their commitment to innovation and sustainable solutions, Shuliy enabled the wood processing facility to embark on a journey towards efficiency, profitability, and environmental responsibility.

Do you need a high-quality sawdust briquette machine to get more profits? If your answer is yes, please fell free to contact us.