Rotary Sawdust Dryer Machine | Sawdust Drying Machine

Sawdust Drying Equipment | Biomass drying Machine

Rotary Sawdust Dryer Machine | Sawdust Drying Machine

Sawdust Drying Equipment | Biomass drying Machine

Features at a Glance

Sawdust dryer machine plays a vital role in the wood processing and biomass energy production industries. It is an essential piece of equipment used to reduce the moisture content of sawdust, making it suitable for various applications. Whether you’re making a wood block or a compressed wood pallet, this machine is indispensable.

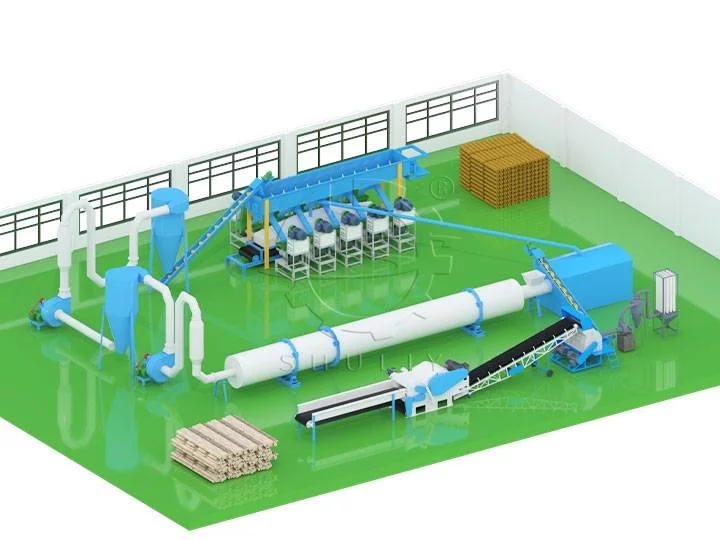

Overview of Rotary Drum Sawdust Dryer Machine

The sawdust dryer machine is a type of equipment that utilizes heated air to remove moisture from sawdust efficiently. It operates on the principle of transferring heat to the sawdust while facilitating the evaporation process. The rotary drum dryer is a common type used in many wood processing facilities due to its high efficiency and energy-saving properties.

What Are the Advantages of Sawdust Dryer Machine?

The sawdust dryer machine offers numerous advantages in the wood processing industry. Firstly, it significantly reduces the moisture content of sawdust, enhancing its combustion properties as biomass fuel. Additionally, dried sawdust finds applications in animal bedding, particleboard production, and other manufacturing processes. The dryer’s high efficiency and energy-saving features make it a cost-effective solution for businesses seeking to optimize their wood waste utilization.

Technical Parameters of Rotary Drum Sawdust Dryer

| Model | Capacity(t/h) | Rotate speed(r/min) | Power(kw) | Initial temperature | Weight(t) |

| SL600x6000 | 0.5-1.5 | 3-8 | 3 | ≤700 | 2.9 |

| SL800x10000 | 0.8-2.5 | 3-8 | 4 | ≤700 | 4.5 |

| SL1200x12000 | 1.8-5 | 3-8 | 7.5 | ≤700 | 14.5 |

| SL1800x12000 | 5-12 | 2-6 | 18 | ≤800 | 25 |

| SL2200x18000 | 10-18 | 1.5-6 | 22 | ≤800 | 53.8 |

| SL2200x20000 | 12-20 | 1.5-6 | 30 | ≤800 | 56 |

| SL3000x20000 | 25-35 | 1.5-5 | 55 | ≤800 | 78 |

The performance of a sawdust dryer machine depends on various technical parameters. These include the processing capacity, drying temperature range, energy consumption, and overall dimensions of the equipment. It is essential to choose a suitable dryer model based on specific requirements to achieve optimal drying results.

Key Application Areas of Sawdust Drying Machine

The sawdust drying machine finds wide applications in different industries. Wood processing plants utilize it to convert wood waste into compressed wood pellets or biomass fuel.

Biomass energy production companies rely on dried sawdust as a crucial feedstock.

Moreover, the agricultural sector employs sawdust drying machines to process agricultural waste for animal bedding and organic fertilizer production.

The dried sawdust can also be used to make sawdust briquettes and wood blocks.

How Does a Rotary Sawdust Dryer Work?

The rotary drum dryer works by feeding sawdust into the rotating drum. As the drum rotates, hot air is blown into the drum, coming into direct contact with the sawdust. The heat from the air transfers to the wet sawdust, causing the moisture to evaporate. The resulting water vapor is then expelled from the sawdust drying system, leaving behind dry and ready-to-use sawdust.

Rotary Drum Sawdust Dryer Machine for Sale

As mentioned above, Shuliy Machinery has a variety of sawdust dryers with different capacities for sale. These sawdust dryer machine models are suitable for different production needs, from small-scale processing to large-scale drying tasks. You can choose according to your needs. If necessary, please feel free to contact us, and we will reply to you as soon as possible.

What Are the Types of Sawdust Drying Machines?

There are several types of sawdust drying machines, each designed to suit specific needs and industrial applications. The main types of sawdust dryers include:

- Rotary Drum Sawdust Dryer Machine: This is the most common and widely used type of sawdust dryer machine. It consists of a large, rotating drum that is heated internally. Wet sawdust is fed into the drum, and hot air is blown through the drum to evaporate the moisture, leaving dry sawdust at the end of the process.

- Flash Dryer: Flash dryers use a high-velocity hot air stream to rapidly dry the sawdust. The wet sawdust is dispersed in the air, and the hot air quickly evaporates the moisture. Flash dryers are suitable for applications that require rapid drying with high heat transfer rates.

- Belt Dryer: In a belt dryer, wet sawdust is spread out on a moving conveyor belt, and hot air is blown through the material to remove moisture. As the sawdust moves along the belt, it gradually dries and is discharged at the end of the process.

- Paddle Dryer (Paddle Mixer Dryer): This type of dryer uses rotating paddles or agitators to agitate the wet sawdust and expose it to heated surfaces. The heat transfer is enhanced due to the constant movement of the material.

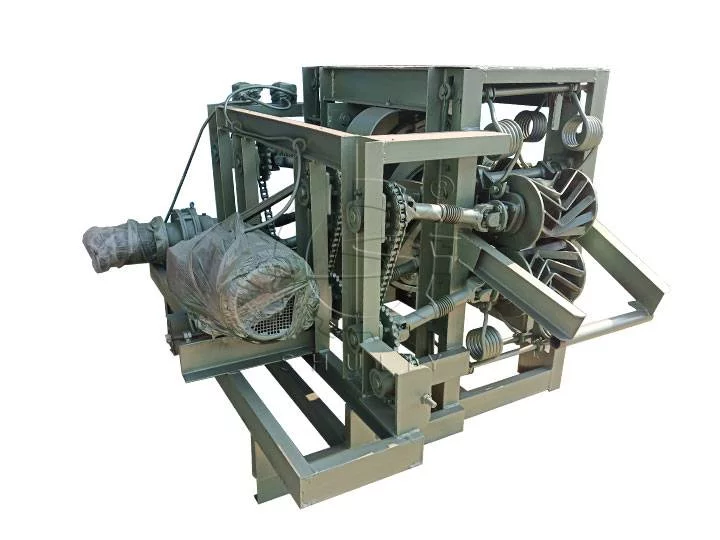

How to Maintain a Rotary Sawdust Dryer Machine?

Maintaining a sawdust dryer machine is essential to ensure its longevity and efficient performance. Proper maintenance helps prevent breakdowns, reduces downtime, and maximizes the dryer’s productivity. Here are some key maintenance tips for a sawdust drying equipment:

Regular Cleaning

Clean the interior and exterior of the dryer regularly to remove sawdust, dust, and other debris that may accumulate during operation. Use a vacuum or compressed air to clean hard-to-reach areas.

Inspecting Belts and Chains

Check the belts and chains for signs of wear and tear. Replace any damaged or worn-out belts and chains promptly to prevent equipment malfunction.

Lubrication

Keep the moving parts well-lubricated to reduce friction and ensure smooth operation. Follow the sawdust dryer manufacturer’s recommendations for the type and frequency of lubrication.

Air Inlet and Outlet Cleaning

Ensure that the air inlets and outlets are free from obstructions to maintain proper airflow and ventilation. Regularly clean or replace air filters to maintain efficient drying performance.

Temperature and Pressure Monitoring

Regularly monitor the temperature and pressure levels within the dryer to ensure they are within the specified range. Any deviations from the optimal levels should be investigated and corrected.

Inspecting Electrical Components

Check electrical connections, motors, and control panels for any signs of damage or loose connections. Promptly address any electrical issues to avoid safety hazards.

Dust Collection System Maintenance

If your sawdust drying equipment is equipped with a dust collection system, ensure that it is functioning correctly. Empty the dust collector regularly to maintain proper airflow and prevent dust buildup.

The sawdust dryer machine proves to be a crucial asset in the wood processing and biomass energy production industries. Its ability to efficiently reduce moisture content makes it an indispensable tool for converting wood waste into valuable resources. Shuliy Charcoal&Wood Machinery stands ready to provide expert solutions tailored to meet specific drying requirements. For more information and personalized consultation, feel free to reach out to us.

Hot Product

Coconut Shell Charcoal Making Machine for Turning Coconut Husk into Charcoal

We have three different types of coconut shell…

Wood Shaving Machine for Animal Bedding

Wood shaving machine is a mechanical device designed…

Vertical Log Peeling Machine

Vertical log peeling machine is specifically designed to…

Disc Wood Chipper for Log Chips Production

Disc wood chipper is a type of machine…

Vertical Bandsaw Mill for Wood Processing Plant

Vertical bandsaw mill is a type of sawmill…

Charcoal Briquette Machine for Bio Coal Briquettes Making

Charcoal briquette machine is a equipment designed to…

Drum Wood Chipper for Making Wood Chips

Drum wood chipper is a specialized equipment used…

Honeycomb Charcoal Briquette Machine for Making Honercomb

Honeycomb charcoal briquette machine, also known as a…

Wood Hammer Mill Machine for Crushing Wood

Shuliy wood hammer mill is equipped with an…