Comprehensive Crusher for Crushing Pallet, Wood Material

Wood Pallet Shredder Machine | Wood Pallet Crusher

Comprehensive Crusher for Crushing Pallet, Wood Material

Wood Pallet Shredder Machine | Wood Pallet Crusher

Features at a Glance

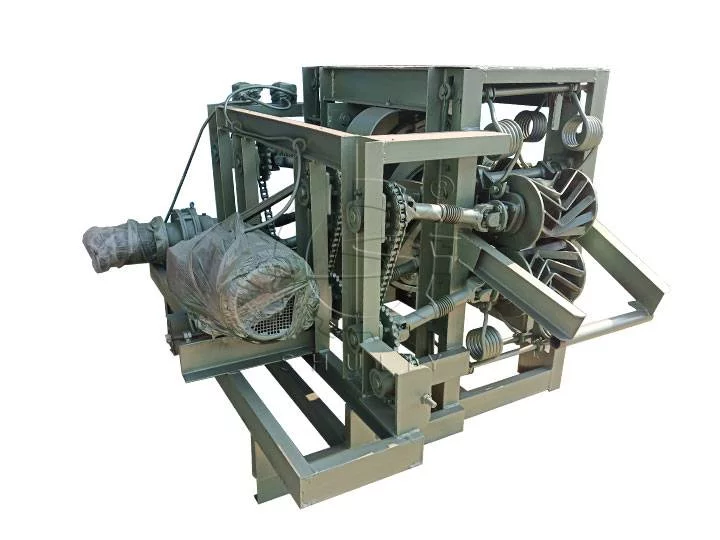

The comprehensive crusher is a multifunctional industrial equipment specially used for crushing wood materials. It shreds wood, chips, and other wood products of all types and sizes, converting them into smaller particles or chips. Integrated shredders include conveying systems, crushing components, sorting and screening devices, etc. to achieve efficient wood shredding and processing processes.

These machines play an important role in wood processing, waste treatment, wood waste recycling, etc., helping to convert bulk wood into raw materials that can be used in other production processes.

The Advantages of Comprehensive Crusher

- High Processing Capacity: These pallet shredders are designed to handle large quantities of materials, making them suitable for industrial-scale operations.

- Versatility: Comprehensive crushers are equipped with various tools and mechanisms that allow them to process different materials with varying hardness, size, and characteristics.

- Automatic Separation: Our comprehensive crushers include mechanisms for automatically separating materials, such as magnetic devices for removing metal contaminants like nails and screws.

- Irregular Output Size: Unlike traditional crushers that produce uniform-sized output, comprehensive crushers might produce irregularly sized pieces. This can be useful in various applications, such as recycling, where the raw materials are repurposed in different ways.

- Automation and Control: Many modern comprehensive crushers come with advanced automation features and controls, enhancing operational efficiency and safety.

Comprehensive Wood Pallet Shredder for Sale

| Model | SL-1300 | SL-1400 | SL-1600 |

| Capacity | 8-10 t /h | 10-15t/h | 20-30t/h |

| Total power | 156.5 kw | 213.5 kw | 233.5kw |

| Input conveyor | 6m | 6m | 6m |

| Output size | Less than 100mm | Less than 100mm | Less than 100mm |

| Blades(pcs) | 20 | 32 | 66 |

| Feeding inlet size | 1300*500mm | 1400*800mm | 1600*800mm |

| Feeding maximum diameter | 400mm | 500mm | 600mm |

| Overall size | 8600*2000*2300mm | 9600*2400*3300mm | 12500*2800*3200mm |

Above are the parameters of three hot-selling comprehensive crushers. Besides, we have other small-scale wood crushing machines for sale. If you want to know more information about the machine, welcome to contact us.

Working Principle of Comprehensive Crusher

The working principle of a comprehensive crusher involves a series of processes that result in the efficient crushing of wood materials. Here’s a general overview of the typical working principle:

Material Feeding

The wood materials, such as old furniture, wooden pallets, large-diameter wood logs, tree roots, and other wood waste, are fed into the wood crusher machine through a feeding mechanism.

Crushing

The materials enter a crushing chamber of the comprehensive crusher where the main action takes place. The crushing chamber contains rotating blades that are mounted on a rotor. The rotor is driven by a powerful motor.

Impact and Friction

As the rotor spins, the hammers or blades impact the wood materials with force. This impact, along with the high-speed rotation, causes the wood to be fractured, torn, and crushed into smaller pieces.

Screening

Due to gravity, the crushed wood particles fall downward and move toward a set of screens located at the bottom of the crushing chamber. These screens have various-sized openings or perforations that allow particles of a certain size to pass through.

Particle Separation

The particles that are smaller than the screen openings pass through and are collected as the desired output. Larger particles remain on the screen surface, where they continue to be subjected to further hammer impacts and grinding.

Magnetic Separation

The comprehensive crusher is equipped with a magnetic drum or magnetic rollers. So these mechanisms can automatically separate any metal contaminants, such as nails or screws, from the crushed wood particles.

Structure of Comprehensive Pallet Shredder

The construction of an integrated shredder usually includes multiple components for efficient shredding and processing of wood-based materials. The following are the main components of the comprehensive pallet shredder.

- Feeding system: Conveyor belts are used to convey woody material to the crushing chamber.

- Crushing chamber: The knife roller in the crushing chamber is used to crush woody materials. The knives apply impact and cutting force to the wood material while rotating at high speed.

- Screening device: The screen is located at the bottom of the crushing chamber and is used to separate broken particles of different sizes.

- Automatic separation device: The magnetic suction device is used to automatically separate metal impurities from wood particles.

- Discharge system: The material system is used to discharge the crushed wood particles from the crushing cavity, including the discharge port and the conveyor belt.

What Kind of Raw Materials Can the Comprehensive Crusher Crush?

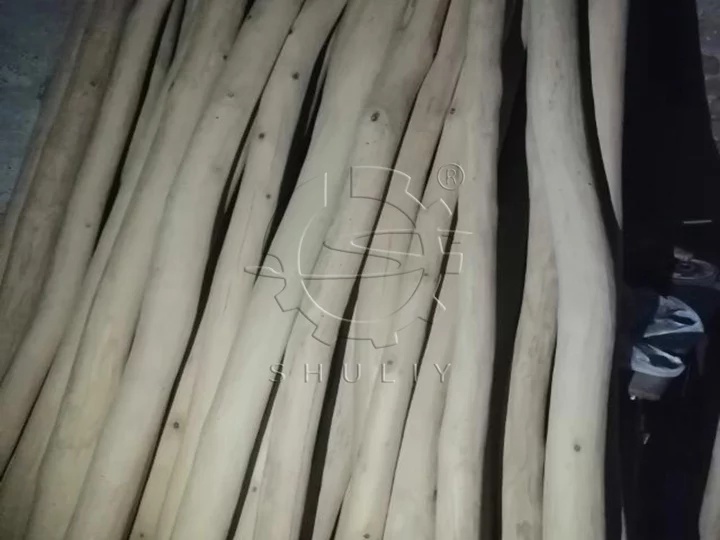

Comprehensive crusher designed specifically for crushing wood materials can typically handle a variety of raw materials commonly found in the wood processing and recycling industries

- Wood Logs and Timber: This includes large-diameter wood logs, timber, and lumber that need to be broken down into smaller pieces for further processing.

- Wooden Pallets: Used or discarded wooden pallets can be crushed to facilitate recycling and repurposing.

- Wooden Furniture: Old or discarded wooden furniture pieces can be crushed to recover wood for recycling purposes.

- Wooden Panels and Boards: Wood panels, plywood, and other wooden boards can be processed for recycling or reuse.

- Wooden Construction Debris: Wood waste generated from construction sites, such as demolished structures or discarded construction materials, can be crushed and processed.

What Is the Price of Comprehensive Crusher?

The cost of a comprehensive wood pallet shredder can vary greatly depending on several factors including manufacturer, model, capacity, features, and market conditions. In addition, different production capacities can also affect the price, and machines with higher production capacity are usually more expensive. In our company, we have machines with output ranging from 8-30 tons for customers to choose from. If you need this machine, please feel free to contact us, and we will contact you as soon as possible.

How to Use the Comprehensive Wood Pallet Shredder Machine?

Preparation of the work area

Make sure that the operating area is clean and tidy, and that there is sufficient space and ventilation. There should be no unnecessary obstacles in the way when operating the comprehensive wood pallet shredder machine.

Wear personal protective equipment (PPE)

Wear appropriate PPE such as hard hats, goggles, earplugs, gloves, and protective clothing when operating the comprehensive crusher.

Inspect the crusher

Before use, carefully inspect all parts of the comprehensive crusher to ensure that there are no loose bolts, damaged parts or other abnormalities.

Starting the crusher

Start the comprehensive wood pallet crusher as instructed in the operator’s manual. Make sure the power and control switches are in the proper position.

Placement of Raw Material

Gradually place the wood raw material to be crushed into the crushing chamber. Take care to place the proper amount of material according to the design and capacity of the crusher.

Monitor operation

Closely monitor the operation of the comprehensive crusher during operation. Make sure there are no unusual noises, vibrations, or other problems.

Clean up the work area

At the end of the operation, clean up the work area to ensure no wood chips or debris remain in the operating area.

Wood Crusher Machine for Biomass Waste

Wood crusher machine, also known as a wood shredder or…

Wood Hammer Mill Machine for Crushing Wood

Wood hammer mill is a machine designed to pulverize or…

Hot Product

Automatic Shrink Wrap Machine for Packing Charcoal Briquette

Automatic shrink wrap machine is a machine can…

Wood Block Machine | Block Pallet Machine

Wood block machine is a machine that turns…

Vertical Log Peeling Machine

Vertical log peeling machine is specifically designed to…

Honeycomb Charcoal Briquette Machine for Making Honercomb

Honeycomb charcoal briquette machine, also known as a…

Animal Feed Pellet Machine

Animal feed pellet machine can be used in…

Hoisting Carbonizer Machine

Hoisting carbonizer machine is a equipment make charcoal…

Charcoal Briquettes Dryer for Charcoal Drying

The Shuliy charcoal briquettes dryer is a hot…

Double Roller Wood Debarker Machine for Wood Processing

Double roller wood debarker machine can handle various…

Wood Crusher Machine for Biomass Waste

Wood crusher machine is a mechanical device used…