What Happens During Carbonization?

Carbonization is a fascinating process that involves the conversion of organic materials into charcoal through the application of high heat in an oxygen-limited environment. In this article, we will delve into the intricacies of carbonization, explaining its significance, and shedding light on the design of our innovative carbonization furnace for charcoal production.

What Is Carbonization?

Carbonization is a natural process that occurs over thousands of years in the Earth’s crust, resulting in the formation of fossil fuels like coal. However, with the aid of modern technology, carbonization can be accelerated and controlled to efficiently produce charcoal from various renewable sources.

During carbonization, organic materials, such as wood, coconut shells, or agricultural waste, undergo thermal decomposition in the absence of oxygen. This controlled pyrolysis process breaks down complex organic compounds, releasing volatile gases and leaving behind solid carbon residue known as char or biochar.

The Role of a Charcoal Making Furnace

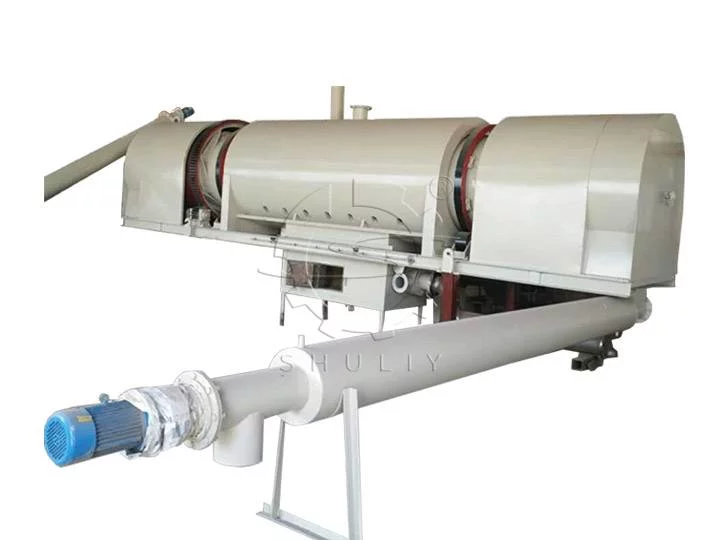

A carbonization furnace plays a crucial role in the carbonization process by providing the ideal conditions for pyrolysis to occur. Our state-of-the-art charcoal making furnace incorporates innovative design elements to maximize efficiency, yield high-quality charcoal, and minimize environmental impact.

The Design of Carbonization Furnace

- Oxygen-Limited Environment: Our carbonization furnace is engineered to create an oxygen-limited environment. By limiting the oxygen supply, we prevent the complete combustion of organic materials and promote the production of carbon-rich char.

- Temperature Control: Precise temperature control is essential during carbonization to optimize the production of charcoal. Our furnace utilizes advanced heating technology, allowing for accurate temperature monitoring and adjustment to ensure consistent and efficient carbonization.

- Gas Recycling System: Our carbonization furnace features a sophisticated gas recycling system. The volatile gases produced during carbonization, such as methane and hydrogen, are captured and utilized as an additional source of energy. This system not only reduces waste but also makes the process more sustainable and cost-effective.

What Are the Benefits of Carbonization?

Carbonization offers several benefits, both from an environmental and practical standpoint:

- Charcoal Production: The main outcome of carbonization is the production of high-quality charcoal. Charcoal is widely used as a fuel source, particularly in industries such as metallurgy, agriculture, and cooking. Its high carbon content and low impurities make it an excellent energy source with a long burn time and consistent heat output.

- Waste Reduction: Carbonization provides a sustainable solution for managing organic waste materials. By converting agricultural residues, wood scraps, and other biomass into charcoal, we reduce landfill waste and contribute to a cleaner environment.

Carbonization is a vital process that transforms organic materials into valuable charcoal, offering numerous environmental and practical benefits. With our advanced carbonization furnace design, we aim to maximize efficiency and sustainability in the production of high-quality charcoal. By incorporating cutting-edge technology and adhering to strict environmental standards, our charcoal making furnace sets new benchmarks in carbonization furnace design and performance.