Biomass Charcoal Briquettes Machine for Sale in Kenya

In the heart of East Africa lies the beautiful country of Kenya, known for its diverse landscapes and vibrant culture. However, like many developing nations, Kenya faces the challenge of balancing economic growth with environmental conservation. Shuliy Wood&Charcoal Machinery, a leading provider of biomass charcoal making machines, has played a pivotal role in assisting Kenya’s transition towards sustainable energy sources through its cutting-edge charcoal briquette extruder machines.

The Charcoal Industry in Kenya

The charcoal industry has long been a significant contributor to Kenya‘s economy, providing a source of income for numerous households and supporting local businesses. However, the traditional methods of charcoal production, often involving the cutting down of trees and unsustainable practices, have led to deforestation and environmental degradation. This prompted the need for an alternative and sustainable solution.

Enter Shuliy Wood & Charcoal Machinery

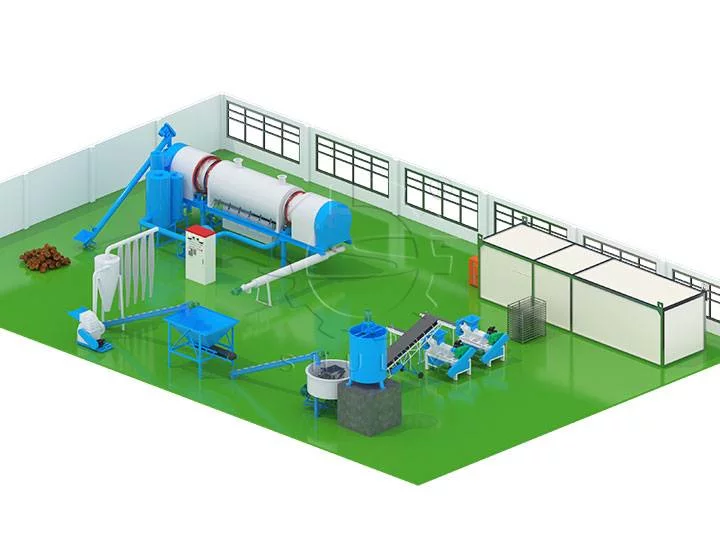

Shuliy Wood & Charcoal Machinery recognized the pressing need for a more environmentally friendly approach to charcoal production in Kenya. In collaboration with local partners and organizations, the company introduced its innovative biomass charcoal making machine. This machine employs a state-of-the-art charcoal briquette machine, which transforms biomass materials into high-density and efficient charcoal briquettes without the need for harmful binding agents.

Key Benefits of the Biomass Charcoal Making Machine

- Environmental Conservation: One of the primary advantages of the biomass charcoal making machine is its contribution to environmental conservation. By utilizing agricultural waste, sawdust, and other biomass materials as feedstock, the machine minimizes the reliance on traditional wood-based charcoal production. This helps preserve Kenya’s precious forests and biodiversity.

- Empowerment of Local Communities: Shuliy’s machines are designed with local communities in mind. The machines are user-friendly and require minimal technical expertise to operate, empowering local entrepreneurs and providing them with a sustainable source of income.

- Higher Efficiency: The charcoal briquette extruder machine ensures higher efficiency in the charcoal production process. It creates uniform and dense briquettes that burn longer and produce less smoke compared to traditional charcoal, offering consumers a cleaner and more efficient cooking fuel.

- Reduced Carbon Emissions: The transition from traditional charcoal production methods to the biomass charcoal making machine leads to a significant reduction in carbon emissions. This aligns with global efforts to combat climate change and promotes Kenya’s commitment to a greener future.

Case Study: Impact on a Kenyan Community

In the rural community of Muhuru Bay, located on the shores of Lake Victoria, the introduction of Shuliy’s biomass charcoal making machine has sparked transformative change. Previously, the community heavily relied on wood-based charcoal production, contributing to deforestation in the area. With the assistance of Shuliy’s technology and training, local entrepreneurs established a cooperative to produce biomass charcoal briquettes.

The impact has been remarkable

- Economic Upliftment: The cooperative has provided new economic opportunities for women and youth who are actively involved in collecting biomass materials, operating charcoal briquette extruder machines, and marketing the final products.

- Improved Indoor Air Quality: The higher efficiency and lower smoke emissions of the briquettes have improved indoor air quality in households, reducing respiratory illnesses among community members.

- Reforestation Efforts: With reduced demand for wood-based charcoal, the community has been able to invest time and resources into reforestation projects, promoting the revival of local flora and fauna.

- Knowledge Transfer: Shuliy’s training programs have equipped community members with valuable skills in operating and maintaining the machines, ensuring the long-term sustainability of the project.

Shuliy Wood & Charcoal Machinery’s collaboration with Kenyan communities showcases the potential of technology to drive positive change. By introducing the biomass charcoal making machine and the charcoal briquette extruder, the company has not only provided an innovative solution to a pressing environmental challenge but has also empowered local communities and contributed to Kenya’s sustainable development goals. As the nation continues its journey towards a greener and more prosperous future, Shuliy remains a beacon of hope and progress in Kenya’s sustainable energy transition.