Is investing in a hookah charcoal production line profitable?

In hookah bars, pubs, and home gatherings around the world, hookah culture is gaining popularity at an unprecedented pace. At the heart of this social ritual lies a seemingly unassuming yet indispensable consumable—hookah charcoal. Consequently, the market demand for high-quality hookah charcoal continues to rise.

So, can investing in a hookah charcoal production line actually turn a profit?

Profit margin from raw materials to finished product

The core appeal of the hookah charcoal business lies in its substantial added value. Let’s break down the numbers.

- Raw material costs:

High-quality hookah charcoal typically uses coconut shell charcoal powder or bamboo charcoal powder. These powders have relatively low wholesale costs, especially at the source.

Our comprehensive estimate indicates that the total raw material cost for producing one ton (1,000 kg) of finished product, including charcoal powder and food-grade natural binders, ranges from $500 to $700 USD. Taking an intermediate value of $600 USD/ton, this equates to $0.60 USD/kg.

- Market value of finished product:

Hookah charcoal is typically sold wholesale or retail in 1-kilogram boxes.

In international wholesale markets (e.g., exports to Europe, the Middle East, or North America), high-quality hookah charcoal in 1-kilogram packaging usually retails for $2.50–$4.00 per kilogram. We adopt a conservative wholesale price of $3.00 per kilogram.

Value increase calculation:

You invested $0.60 USD in raw materials, creating a wholesale value of $3.00 USD.

This means that simply through shaping and processing, the raw material’s value increased fivefold! This enormous profit margin is unmatched by many industries.

Calculating actual profit and return on investment

Now, incorporating operational costs, we calculate the profitability of a standard production line.

Estimated Net Profit per Kilogram:

- Wholesale selling price: $3.00 USD

- Minus: raw material cost $0.60 USD

- Minus: comprehensive operational costs (labor, electricity, packaging, facility, etc.) estimated at $0.40 USD

- Final net profit per kilogram ≈ $2.00 USD

Production line profitability analysis:

Assuming you invest in a medium-sized production line with an output of 250 kg/hour.

- Daily output (based on 8-hour shifts): 250 kg/hour × 8 hours = 2,000 kg/day

- Daily net profit: 2,000 kg × $2.00/kg = $4,000/day

- Monthly net profit (based on 22 working days): $4,000/day × 22 days = $88,000/month

Return on investment analysis:

Based on this exceptionally substantial monthly profit, the cost of investing in a complete hookah charcoal production line is highly likely to be fully recovered within just 2-4 months. Thereafter, this production line will generate a steady stream of consistent profits for you.

Shuliy hookah charcoal production line for sale

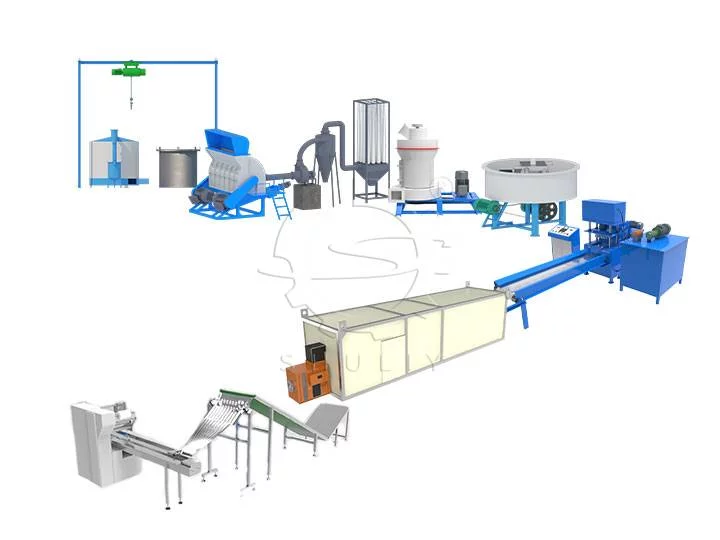

The aforementioned ideal profit model must be built upon a set of efficient, reliable production equipment. Our hookah charcoal production line is precisely designed to achieve this goal:

Powerful pressure system: we employ a high-tonnage hydraulic press system capable of compressing charcoal powder into high-density, high-hardness charcoal blocks.

Precision molding technology: molds ensure every hookah charcoal piece is uniformly sized and shaped, with a smooth, professional finish. Flexible mold customization allows production of popular market formats, including square, round, and stick shapes.

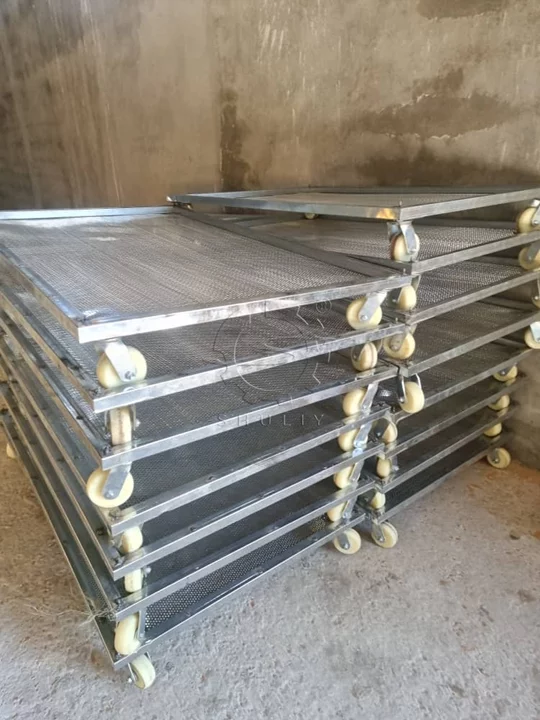

Scientific mixing and drying solutions: from mixers to drying chambers, we provide complete production to eliminate losses caused by improper processing.

Get your own business!

Data indicates that investing in hookah charcoal production lines is not only a profitable venture but also a strategic investment offering high returns and rapid payback.

Driven by global market demand and leveraging the substantial added value of the product alongside cost advantages from automated production, now is the optimal time to enter this industry.

Contact us immediately to receive a customized hookah charcoal production line solution and a detailed quotation!