BBQ Charcoal Briquettes Machine

Barbecue Charcoal Machine | BBQ Coal Making Machine

BBQ Charcoal Briquettes Machine

Barbecue Charcoal Machine | BBQ Coal Making Machine

Features at a Glance

BBQ charcoal briquettes machine refers to an industrial device used to make charcoal briquettes specifically designed for barbecues (BBQ stands for “barbecue”). You can make the round, oval, pillow, and many other shapes and sizes of BBQ charcoal with this machine. Output up to 30t/h.

Shuliy charcoal ball press machines can convert various types of charcoal powder, or other biomass materials into uniform and compact briquettes suitable for use as a cooking fuel in barbecues, grills, and other similar applications.

The Benefits of Coal Ball Briquette Machine

- Uniformity and Consistency: The Shuliy coal ball briquette machine guarantees uniform briquettes, promoting consistent heat release and cooking throughout your grilling session.

- High Efficiency: The briquettes produced by the Shuliy BBQ charcoal briquettes machine are dense and burn longer, providing extended cooking times without the need for frequent refueling.

- Environmentally Friendly: This machine can make barbecue charcoal from carbon powder made from a wide variety of biomass raw materials. This can effectively reduce biomass waste.

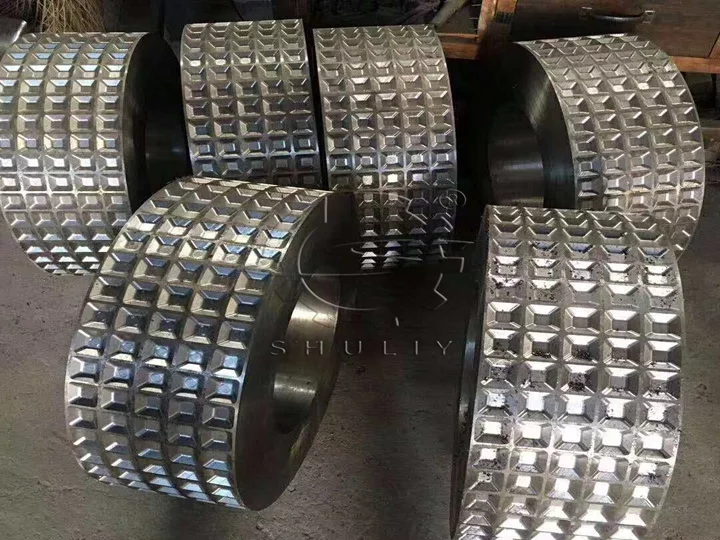

- Customization: You can very easily change the molds in the coal ball briquette machine to change the shape and size of the finished product.

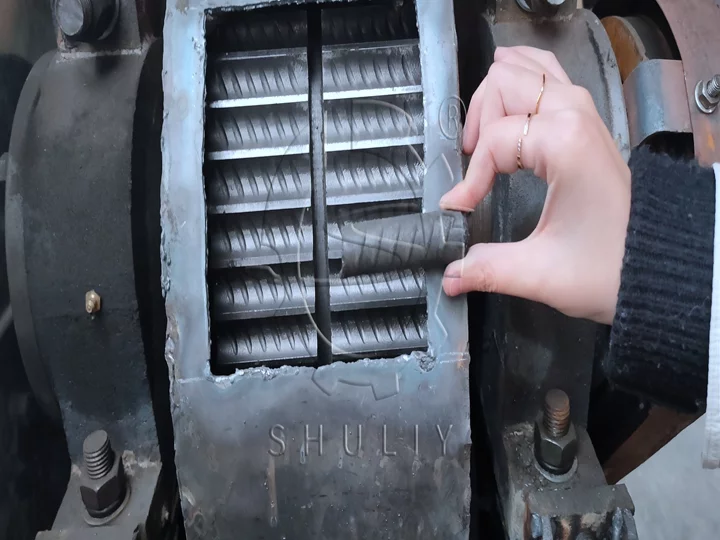

Moulds for Barbecue Charcoal

In our company, we have many different shapes of BBQ charcoal molds for customers to choose from. You can choose the right grinder according to your needs.

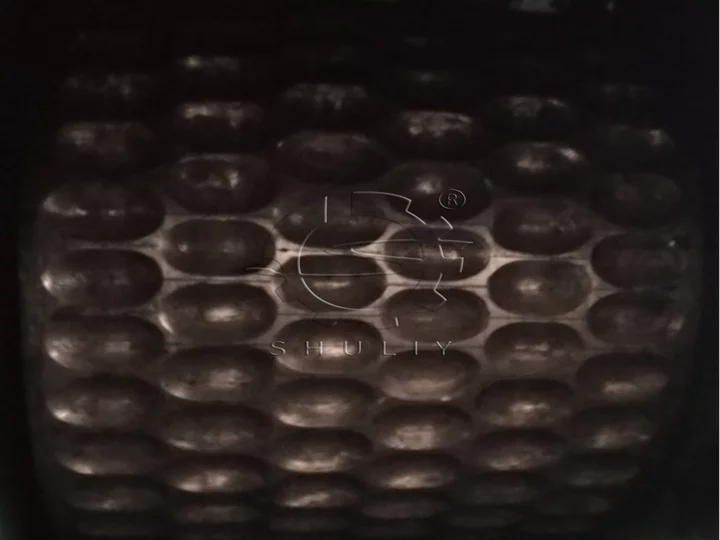

Finished BBQ Charcoal Ball Display

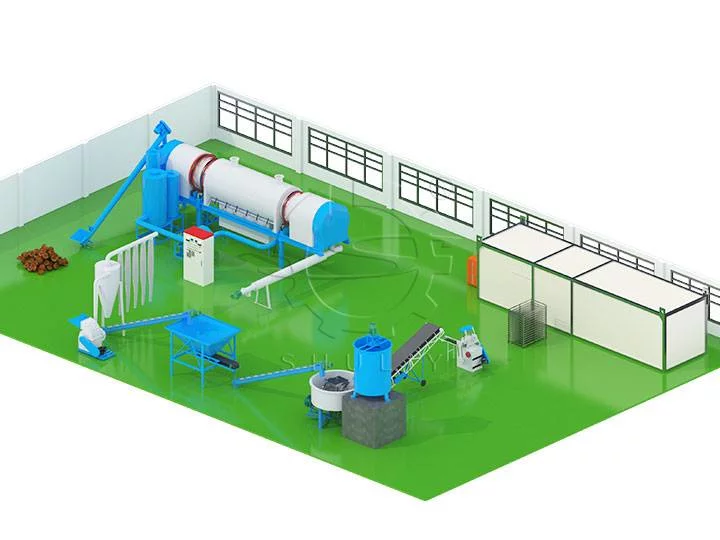

How BBQ Charcoal Is Made?

The BBQ charcoal briquettes machine’s ingenious mechanism involves a series of steps. Firstly, the raw materials, such as charcoal powder or biomass waste, are fed into the mixer, where they are blended with a binder and, optionally, additives to enhance burning properties. The mixture then enters the BBQ charcoal briquettes machine, undergoing compression that results in the formation of sturdy briquettes. Therefore, barbecue charcoal needs a complete barbecue charcoal production line to be made.

Technical Specification of BBQ Charcoal Briquettes Machine

The following is a variety of charcoal ball press machines with different capacities. Their outputs are 1-3 tons per hour, 3-5 tons per hour, 4-7 tons per hour, 5-10 tons per hour, and 8-13 tons per hour. You can choose the charcoal ball press machine you want according to your own needs.

| Model | SL-290-2 | SL-360-2 | SL-430-2 | SL-500-2 | SL-650-2 |

| Capacity(t/h) | 1-3 | 3-5 | 4-7 | 5-10 | 8-13 |

| Power(kw) | 5.5-7.5 | 7.5-11 | 15-18.5 | 22-30 | 37-55 |

| Roller size(mm) | 290×200 | 360×250 | 430×250 | 500×300 | 650×350 |

| Spindle speed(r/min) | 12-15 | 12-15 | 12-15 | 12-15 | 10-13 |

| Dimension(m) | 1.6×1.2×1.4 | 2.1×1.3×1.76 | 2.3×1.53×1.9 | 2.6×1.75×2.1 | 3.42x2x2.2 |

What Is the Capacity of BBQ Charcoal Briquettes Machine?

As shown in the picture above, at Shuliy Charcoal Machinery, we have a variety of BBQ coal ball briquette machines for sale with different capacities. Their outputs are 1-3 tons per hour, 3-5 tons per hour, 4-7 tons per hour, 5-10 tons per hour, 8-13 tons per hour, 12-17 tons per hour, 15-20 tons per hour, 20-30 tons per hour, etc. Customers can choose their own BBQ charcoal briquettes machine according to their needs.

What Is the Price of a BBQ Charcoal Machine?

The price of a BBQ charcoal machine can vary widely depending on several factors, such as the brand, production capacity, technical specifications, and the country or region of purchase.

Generally, BBQ charcoal briquettes machines can range in price from a few hundred to several thousand dollars, with more advanced and high-capacity machines being on the higher end of the price spectrum.

To get accurate and up-to-date pricing information, please contact Shuliy charcoal machinery. We will give you a detailed quotation.

Why Choose BBQ Charcoal Made by Coal Ball Press Machine?

Flavor Infusion: The consistent density and even burning of the briquettes ensure that your grilled delicacies are infused with that delightful smoky flavor everyone craves.

Precise Heat Control: With uniform briquettes, you can better regulate cooking temperatures, preventing overcooking or undercooking of your grilled food.

Longer Cook Times: The high density of the briquettes translates to extended cook times, allowing you to enjoy lengthy gatherings without interruptions.

Customer Case

In April 2023, a Mexican customer purchased this high-quality BBQ charcoal ball making machine from our company. If you want to read more about this customer case please click here.

What Is Barbecue Charcoal Made Of?

Barbecue charcoal is typically made from carbon-rich materials obtained from various sources. The bbq charcoal making machine can make barbecue charcoal from the following ingredients.

- Wood: Traditional charcoal is often made from hardwood species such as oak, hickory, maple, beech, or fruitwoods like apple and cherry. These woods contain a high amount of carbon and low amounts of impurities, making them ideal for charcoal production.

- Coconut Shells: Coconut shell charcoal is becoming increasingly popular as an eco-friendly alternative. It is made from coconut shells, a byproduct of the coconut industry, which are carbonized to produce charcoal.

- Bamboo: Bamboo charcoal is another sustainable option. Bamboo is a fast-growing plant that is widely available, and its charcoal has good burning properties.

- Sawdust: In some cases, sawdust from woodworking operations or sawmills is used to produce charcoal. It can be compacted into briquettes or processed into lump charcoal.

BBQ Charcoal Packing Machine | Quantitative Packing Machine

BBQ charcoal packing machines are specialized equipment designed to automate…

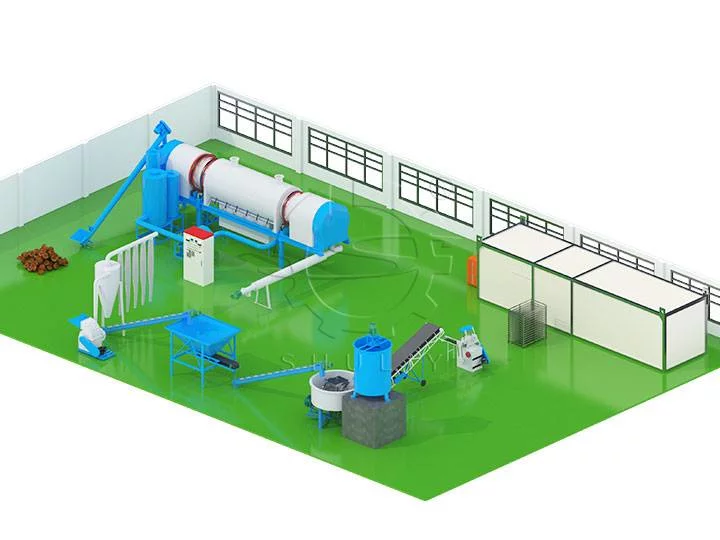

Barbecue Charcoal Production line

The barbecue charcoal production line represents a systematic assembly of…

BBQ Coal Press Machine for Sale in Mexico

In April 2023, a transformative shipment set out from Shuliy…

Shuliy Barbecue Charcoal Maker Machine Shipped to Thailand

In December 2022, a high-quality Barbecue Charcoal Maker Machine departed…

Hot Product

Charcoal Briquette Machine for Bio Coal Briquettes Making

Charcoal briquette machine is a equipment designed to…

Charcoal Briquettes Dryer for Charcoal Drying

The Shuliy charcoal briquettes dryer is a hot…

Efficient Compressed Wood Pallet Machine for Sale

Shuliy's compressed wood pallet machine is equipped with…

Shisha Charcoal Packing Machine

Shisha charcoal packing machine has efficient packaging speed…

Charcoal Mixer Machine for Mixing Charcoal Powder, Water and Binder

Charcoal mixer machine utilize mechanisms such as rolling,…

Horizontal Band Saw Mill

Horizontal band saw mill is a type of…

Animal Feed Pellet Machine

Animal feed pellet machine can be used in…

BBQ Charcoal Packing Machine | Quantitative Packing Machine

BBQ charcoal packing machines are specialized equipment designed…

Hoisting Carbonizer Machine

Hoisting carbonizer machine is a equipment make charcoal…