Shisha Charcoal Production Line for Making Round/Cube Hookah Charcoal

Hookah Charcoal Production Line | Shisha Charcoal Machinery

Shisha Charcoal Production Line for Making Round/Cube Hookah Charcoal

Hookah Charcoal Production Line | Shisha Charcoal Machinery

Features at a Glance

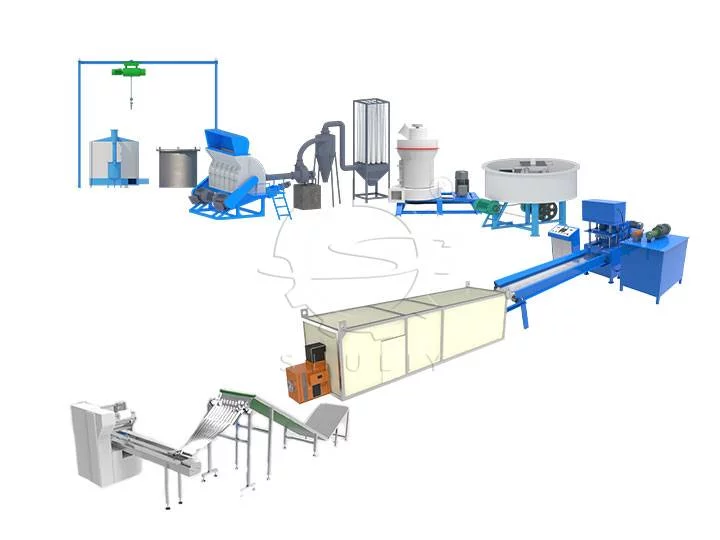

The Shisha Charcoal Production Line refers to a series of machines and equipment designed for the manufacturing of shisha charcoal systematically and efficiently. It can convert biomass raw materials into hookah/shisha charcoal on a large scale.

Shuliy Machinery has a series of shisha charcoal making machines that can help you make high-quality shisha charcoal.

How Is Hookah Charcoal Made?

Shisha Charcoal Production Line operates through a series of steps to transform raw materials into high-quality shisha charcoal briquettes. The complete process of making hookah charcoal includes carbonization, crushing, mixing, briquetting, drying, and packaging.

Carbonization

The process begins with raw materials, such as coconut shells, bamboo, or other plant-based materials, being loaded into a carbonization furnace. The furnace heats the raw materials at a controlled temperature in the absence of oxygen, a process known as carbonization. This converts the raw materials into carbonized charcoal with high carbon content and reduced impurities.

Crushing

The carbonized charcoal is then conveyed to a hammer charcoal crusher or similar equipment. In this step, the large charcoal pieces are crushed into charcoal powder. Proper crushing ensures uniformity in the charcoal powder and facilitates the subsequent mixing process.

Mixing

The crushed charcoal powder is transferred to a charcoal mixer, where they are combined with a binding agent. Common binding agents include starch or natural adhesives. The binding agent helps hold the charcoal particles together during the compression process.

Briquetting

The mixed charcoal and binding agent blend are fed into a shisha charcoal briquette machine or shisha charcoal press. This machine exerts high pressure on the mixture, compressing it into characteristic disc-shaped shisha charcoal briquettes. The pressure and mold used in the hookah charcoal making machine determine the size and shape of the briquettes.

Drying

Once the shisha charcoal briquettes are formed, they are moved to a drying room or chamber. In this stage, excess moisture is removed from the briquettes through controlled drying. Drying ensures that the shisha charcoal reaches the desired moisture content, making it suitable for packaging and use.

Packaging

After drying, the shisha charcoal briquettes are ready for packaging. They are carefully arranged and packed using a shisha charcoal packing machine. The packaging process ensures that the final products are presented neatly and ready for distribution and sale.

What Machines Are Involved in a Shisha Charcoal Production Line?

A Shisha Charcoal Production Line involves several machines, each serving specific functions and working together to complete the production process of shisha charcoal. Here are several common machines found in a Shisha Charcoal Production Line:

Carbonization Furnace

The carbonization furnace is the first step in the Shisha Charcoal Production Line. It is used to carbonize the raw materials, creating carbonized charcoal. The furnace is a sealed high-temperature chamber that heats the raw materials under anaerobic conditions, transforming them into carbonized wood charcoal.

Hammer Charcoal Crusher

After carbonization, the charcoal is often in large chunks. To further process the charcoal, it needs to be crushed into suitable-sized particles. The Hammer Charcoal Crusher Machine is used to crush the large charcoal pieces into smaller particles.

Charcoal Mixer

The crushed charcoal particles need to be mixed with a binding agent to enhance their cohesion during the compression process. The Charcoal Mixer is used to thoroughly mix the crushed charcoal particles with starch or other binding agents to ensure a uniform mixture.

Shisha Charcoal Press Machine

The mixed charcoal and binding agent blend are fed into the Shisha Charcoal Briquette Machine. This machine exerts high pressure on the mixture, compressing it into the characteristic disc-shaped shisha charcoal briquettes, which are the final products of the shisha charcoal briquette forming line.

Drying Room

After compression, the shisha charcoal briquettes contain a certain amount of moisture and need to undergo a drying process. The shisha charcoal briquettes are transferred to a drying room or chamber, where excess moisture is removed through controlled drying to achieve the desired moisture content.

Shisha Charcoal Packing Machine

Once the shisha charcoal briquettes are dried, they are ready for packaging. The Shisha Charcoal Packing Machine is used to neatly package the shisha charcoal briquettes for distribution and sale.

How Much Does a Shisha Charcoal Production Line Cost?

The cost of a Shisha Charcoal Production Line can vary significantly depending on various factors, such as the production capacity, automation level, quality of machinery, and the supplier or manufacturer. Generally, the cost of a Shisha Charcoal Production Line can range from several thousand dollars to several hundred thousand dollars.

Key Factors That Influence the Cost of a Shisha Charcoal Production Line

- Production Capacity: The production capacity of the line is a significant cost driver. Higher production capacity machines will generally cost more than those with lower capacity.

- Automation Level: The level of automation in the shisha charcoal production line can affect the cost. Fully automated lines with advanced technology may be more expensive than semi-automated or manual production lines.

- Machinery Quality: The quality and brand of the machinery used in the production line can impact the cost. High-quality machines from reputable manufacturers may have a higher initial cost but can offer better performance and durability in the long run.

- Customization: If you require specific customization for the production line to meet unique requirements, this may add to the overall cost.

What Is the Production Capacity of a Shisha Charcoal Making Line?

The production capacity of a shisha charcoal making line can vary depending on the size and configuration of the equipment used. Shisha charcoal production lines are available in various capacities to cater to different production needs, ranging from small-scale operations to large commercial production facilities. Here are some common production capacity options for Shisha Charcoal Production Lines:

- Small-scale Production Lines: These lines are suitable for small businesses or startups and typically have a production capacity of around 500 kg to 1 ton of shisha charcoal per day.

- Medium-scale Shisha Charcoal Briquette Forming Line: Medium-sized production lines are designed for businesses with moderate production requirements. Their production capacity can range from 1 ton to 5 tons of shisha charcoal per day.

- Large-scale Production Lines: Large-scale lines are suitable for established businesses or commercial operations with high production demands. Their production capacity can exceed 5 tons per day, reaching up to 10 tons or more.

It’s important to note that the production capacity can be further customized based on specific requirements and the type of machinery used. We can offer flexibility in configuring the production line to match the needs of individual customers.

Where Can I Find Manufacturers of Shisha Charcoal Production Lines?

- Online Search: Conduct an online search using search engines like Google. Use keywords such as “Shisha Charcoal Production Line manufacturers” or “Shisha Charcoal Machine suppliers” to find relevant results. You are likely to come across Shuliy Charcoal&Wood Machinery during your search.

- Industry Exhibitions and Trade Shows: Visit industry exhibitions and trade shows related to charcoal and wood machinery. Manufacturers often participate in such events to showcase their products and innovations. You might find Shuliy Charcoal&Wood Machinery or similar companies in such exhibitions.

- Industry Directories: Check industry directories and platforms specializing in machinery and equipment. These directories often list companies that offer Shisha Charcoal Production Lines. Shuliy Charcoal&Wood Machinery may be listed in such directories.

Different Hookah Charcoal Production Lines for You to Choose From

In our company, we provide different types of hookah charcoal production lines for customers to choose from, including round/tablet charcoal plants and cube/square cube/square charcoal plants. These lines can be customized according to customer’s needs and preferences.

The round hookah charcoal production line is suitable for making traditional round hookah charcoal, which is the most common hookah charcoal shape. The square shisha charcoal production line is suitable for making unique square shisha charcoal, which is more popular in certain markets and occasions.

Also, our hookah charcoal production line has flexible size options. Customers can choose different sizes of shisha charcoal according to their own needs to meet the requirements of different markets and customers. Our professional team will customize according to customers’ specifications and requirements, and ensure the performance and production efficiency of the production line to reach the best state.

Whether you need a round hookah charcoal production line or a square shisha charcoal production line, as well as different sizes of shisha charcoal, we can provide you with a suitable solution.

What Are the Raw Materials Used in Shisha Charcoal Production?

In Shisha Charcoal Production, various raw materials can be used to create shisha charcoal or hookah charcoal briquettes. The choice of raw materials can influence the quality, burning characteristics, and aroma of the final product. Some common raw materials used in Shisha Charcoal Production include coconut shells, bamboo, fruit wood, hardwood, sawdust, and palm kernel shells.

It’s important to note that the choice of raw material can impact the quality, flavor, and burning characteristics of shisha charcoal. You can use single raw materials or create blends of different materials to achieve specific smoking experiences and meet market preferences.

Reasons for Choosing Shuliy Machinery

- Quality Assurance: Shuliy Machinery is known for its commitment to producing high-quality machinery. Our products are made using top-notch materials and advanced manufacturing techniques, ensuring durability, efficiency, and reliable performance.

- Wide Product Range: Shuliy Machinery offers a wide range of wood and charcoal processing machines, including Shisha Charcoal Production Lines, sawdust briquette machines, carbonization furnaces, wood chippers, and more. This extensive product range allows customers to find suitable solutions for their specific needs.

- Customization Options: Shuliy Machinery provides customization options for their machines to meet individual requirements. We understand that different customers may have unique needs, and We are willing to tailor our machines accordingly.

- Industry Expertise: With years of experience in the industry, Shuliy Machinery has acquired valuable expertise in wood and charcoal processing. Our team of professionals has in-depth knowledge to offer expert advice and support to you.

What Quality Standards Should Be Met in Shisha Charcoal Production?

In Shisha Charcoal Production, several quality standards should be met to ensure that the final product is safe, clean, and of high quality. These standards help to meet regulatory requirements, ensure consumer safety, and enhance the overall smoking experience for shisha enthusiasts. Some key quality standards include:

- Purity and Safety: Shisha charcoal should be free from any harmful substances, chemicals, or impurities. It should not contain additives or binders that could negatively impact health. The production process must adhere to safety guidelines to prevent contamination.

- Low Ash Content: High-quality shisha charcoal should have a low ash content to minimize residue during smoking, ensuring a cleaner and more enjoyable experience for users.

- Consistent Size and Shape: The charcoal briquettes should be uniform in size and shape to ensure even and consistent burning. This helps to maintain a steady heat output and enhances the overall smoking performance.

- Stability and Durability: Shisha charcoal should be stable and durable, ensuring that it does not crumble or break easily during handling, transportation, or use in a hookah.

- No Odor or Off-Flavors: The charcoal should be odorless and free from any off-flavors that could affect the taste of the shisha tobacco.

Shisha Charcoal Machine for Making Hookah Charcoal

Shisha charcoal machine, also known as a hookah charcoal machine…

Shisha Charcoal Packing Machine

The shisha charcoal packing machine is a packaging equipment for…

Shisha Charcoal Press Machine for Sale in Nigeria

In May 2021, a state-of-the-art, high-quality shisha charcoal press machine…

Hookah Charcoal Production Line Shipped to Indonesia

In September 2021, Shuliy Charcoal&Wood Machinery embarked on a significant…

What Are the Raw Materials Used to Make Hookah Charcoal?

Hookah charcoal, an essential component of shisha, relies on a…

American Customer Purchased Shisha Charcoal Machine

Recently, our company has successfully exported a 300kg/h shisha charcoal…

How to Make Hookah Charcoal? A Complete Guide to Materials, Process & Equipment

With the growing popularity of hookah culture in the Middle…

Is investing in a hookah charcoal production line profitable?

In hookah bars, pubs, and home gatherings around the world,…

Hot Product

Carbonization Furnace for Charcoal Making

Three different types of carbonization furnaces are used…

Honeycomb Charcoal Briquette Machine for Making Honercomb

Honeycomb charcoal briquette machine, also known as a…

Drum Wood Chipper for Making Wood Chips

Drum wood chipper is a specialized equipment used…

BBQ Charcoal Packing Machine | Quantitative Packing Machine

BBQ charcoal packing machines are specialized equipment designed…

Disc Saw for Wood Cutting

Shuliy's disc saw machine can handle many types…

Automatic Shrink Wrap Machine for Packing Charcoal Briquette

Automatic shrink wrap machine is a machine can…

Coconut Shell Charcoal Making Machine for Turning Coconut Husk into Charcoal

We have three different types of coconut shell…

Horizontal Band Saw Mill

Horizontal band saw mill is a type of…

Animal Feed Pellet Machine

Animal feed pellet machine can be used in…