Animal Feed Pellet Machine

Feed Pellet Mill | Poultry Feed Pellet Making Machine

Animal Feed Pellet Machine

Feed Pellet Mill | Poultry Feed Pellet Making Machine

Features at a Glance

The animal feed pellet machine is a mechanical device used in the agricultural and livestock industry to convert raw materials, such as grains, agricultural residues, and other feed ingredients, into compact and uniform pellets.

These pellets are designed to be a complete and balanced source of nutrition for various animals, such as poultry, livestock, pets, and sometimes even aquatic animals.

The Benefits of Poultry Feed Pellet Machine

- The raw materials can be pelletized without drying.

- Poultry feed pellet machine is widely used in animal husbandry, small, medium, and large scale breeding mills, feed mills, brewing, sugar making, paper making, medicine, tobacco factories, and other industries.

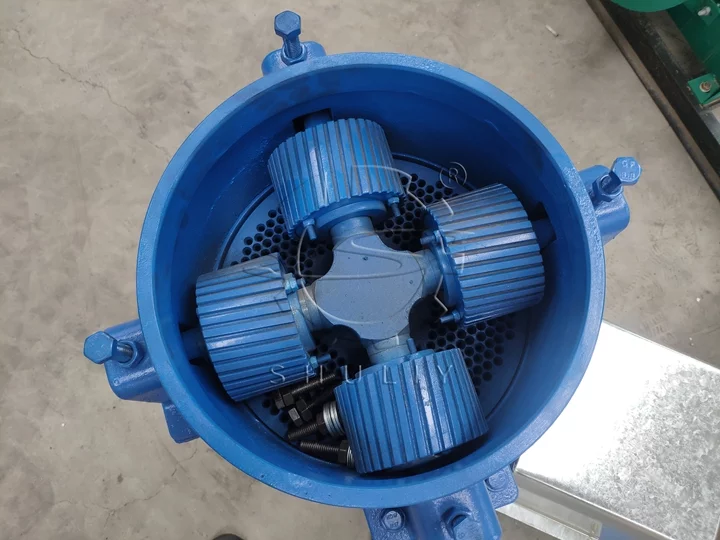

- The molds and pressure rollers inside the machine are made of high-quality alloy steel. This improves the service life of the machine.

- The pellets made by using the Shuliy poultry feed pellet machine are consistent in size and do not easy to be deformed.

- Animal feed pellet machines can easily make multiple sizes of feed pellets to meet different needs.

- The machine is simple to use, you need to turn on the switch to put the raw material into the feed inlet.

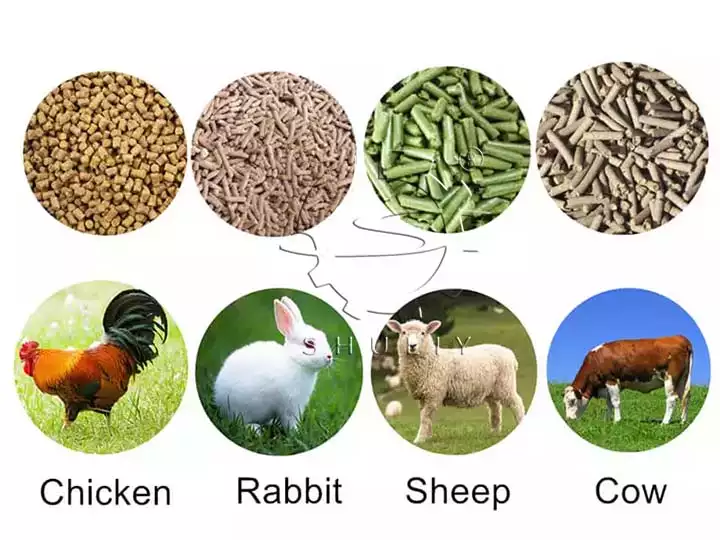

What Kind of Animal Feed Can Be Made in an Animal Feed Pellet Mill?

Animal feed pellet mill can make feed for many different animals, including but not limited to the following categories:

- Poultry feed: This includes feed for chickens, ducks, geese, and other poultry. These feeds often require precise nutritional formulations to meet the growth and production needs of poultry.

- Livestock feeds: Animal feed pellet mills are also suitable for feeds for livestock such as cattle, pigs, and sheep. These feeds are usually formulated taking into account the animal’s stage of growth, meat quality, and other factors.

- Rabbit feed: The feed made by an animal feed pellet mill can meet the special feeding needs of rabbits.

- Pet feed: The feed made by an animal feed pellet mill can be used as feed for cats, dogs, small birds, and other pets. These feeds need to be formulated according to the health needs and tastes of different pets.

- Aquatic feed: At the same time, feed pellets can also be used for aquatic animal feed such as farmed fish and shrimp.

- Special Animal Feed: For some specially farmed animals, such as bees, silkworms, etc., animal feed pellet mills can also be used to make specific feeds.

How Does an Animal Feed Pellet Machine Work?

The next depiction is the animal feed pelleting process, by reading the following content, you can know the working principle of the animal feed pellet mill in detail.

Feeding and Conditioning

The process starts with feeding the raw materials into the animal feed pellet machine. Depending on the specific requirements, the raw materials might undergo conditioning, where they are mixed with water, steam, or other additives to improve their workability and pelletization.

Pelletizing

The conditioned or ground raw materials are then fed into the animal feed pellet machine’s chamber, which houses a die and rollers. The die is a metal plate with small holes, and the rollers press against the die as they rotate. The pressure exerted by the rollers forces the raw materials through the holes in the die, compacting and shaping them into pellets.

Die and Roller Interaction

The die contains holes of a specific size and shape, determining the diameter of the pellets. The rotation of the rollers against the die generates friction and heat, which softens the materials and promotes the binding of particles together. The pellets are formed as they emerge from the die.

Cutting and Sizing

As the pellets exit the die, they are cut to the desired length by a cutting mechanism of the feed pellet making machine. The speed of the cutting mechanism determines the pellet length. The uniform cutting ensures that the pellets are consistent in size, which is crucial for animal consumption and handling.

How to Pack Animal/Poultry Feed Pellets?

Animal feed pellets are packaged using using a quantitative packaging machine. The quantitative packaging machine can set the weight of a single package of feed pellets according to your needs.

The Parameter/Models of Animal Feed Pellet Machine

| Model | SL-F-300 | SL-F-400 | SL-F-450 | SL-F-560-1 | SL-F-560-3 |

| Capacity(kg/h) | 150-300 | 300-500 | 300-700 | 1000-1500 | 2000-2500 |

| Power(kw) | 22+0.37 | 37+0.37 | 55+0.37 | 110+1.5+0.75+0.37 | 160+1.5+0.75+0.37 |

The above are the parameters of the five best-selling animal feed pellet machines, and you can choose the right machine according to your needs.

Small Scale Animal Feed Pellet Machine for Sale

At Shuliy Charcoal&Wood Machinery, the capacity of our small animal feed pellet machine is 150-300 kg per hour. The power is 33±0.37kw.

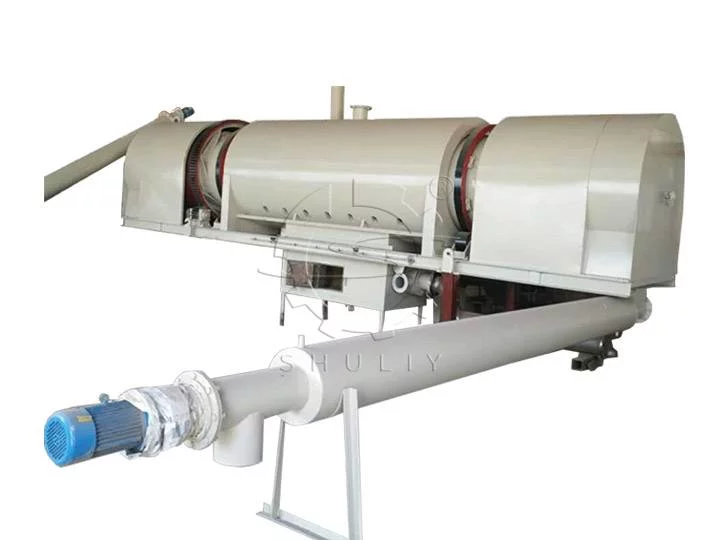

Large Scale Feed Pellet Machine for Sale

At Shuliy Charcoal&Wood Machinery, we also have large animal feed pellet machines for sale. The output of a large feed pellet making machine is 2000-2500 kg/h. The power is 160+1.5+0.75+0.37.

Where to Buy Animal Feed Pellet Machine?

You can buy professional animal feed pellet machines from “Shuliy Charcoal&Wood Machinery”. We offer a wide range of animal feed pellet mills at favorable prices. After purchasing, you will also receive a variety of animal feed pellet recipe sheets. This will help you to produce high-quality pellets according to the nutritional requirements of different animals.

Buying a professional animal feed pellet machine can not only improve the quality and efficiency of feed but also meet the needs of different animal species and realize more effective breeding management. If you are looking for a supplier of animal feed pellet machines, why not contact us for more information about feed pellet making machines and purchase details?

Raw Materials for Feed Pellet Making Machine

- Grains: Corn, wheat, barley, oats, and rice are commonly used as a primary source of energy in animal feed.

- Oilseeds: Soybeans, sunflower seeds, and canola seeds provide protein and essential fatty acids.

- Protein Sources: Soybean meal, fish meal, meat and bone meal, and other protein-rich ingredients are added for animal growth and development.

- Forages and Fiber: Alfalfa, clover, and other forages, as well as fiber-rich ingredients like rice bran, contribute to roughage and gut health.

- Vitamins and Minerals: These are added to ensure animals receive essential nutrients for overall health and performance.

- Additives: These can include vitamins, minerals, enzymes, probiotics, and other supplements to enhance feed quality and animal health.

Animal Feed Granulator Machine Shipped to Australia

25 Animal Feed Pellet Maker Shipped to Saudi Arabia

The landscape of business is ever-evolving, and entrepreneurs around the…

How to Make Animal Feed Pellets?

Producing high-quality animal feed pellets is crucial for ensuring the…

Hot Product

Shisha Charcoal Packing Machine

Shisha charcoal packing machine has efficient packaging speed…

Sawdust Briquette Machine for Making Pini Kay Briquettes

The briquettes produced by the Shuliy machine have…

Wood Block Machine | Block Pallet Machine

Wood block machine is a machine that turns…

Double Roller Wood Debarker Machine for Wood Processing

Double roller wood debarker machine can handle various…

Disc Saw for Wood Cutting

Shuliy's disc saw machine can handle many types…

Automatic Shrink Wrap Machine for Packing Charcoal Briquette

Automatic shrink wrap machine is a machine can…

Continuous Carbonizing Machine for Rice Husk, Sawdust, Bamboo

Continuous carbonizing machine is a kind of equipment…

Charcoal Briquettes Dryer for Charcoal Drying

The Shuliy charcoal briquettes dryer is a hot…

Comprehensive Crusher for Crushing Pallet, Wood Material

Comprehensive crusher is a machine capable of crushing…