How to Make Charcoal Briquettes from Agricultural Waste?

As the world embraces sustainable practices, turning common agricultural wastes into charcoal briquettes is gaining traction for its environmental and economic benefits. In this comprehensive guide, we will take you through the process of making charcoal briquettes using readily available agricultural wastes. We’ll also explore the pivotal role of charcoal machines in this endeavor.

Step 1: Gather and Prepare Agricultural Wastes

Collect a diverse range of agricultural wastes, including rice husks, sawdust, straw, sugarcane bagasse, and crop stalks. Prioritize thoroughly drying these materials to reduce moisture content, which could otherwise hinder the charcoal briquetting process.

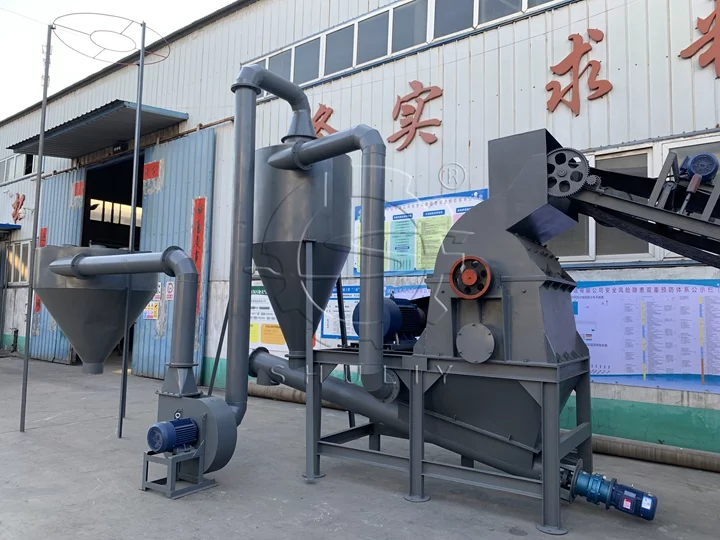

Step 2: Shred or Pulverize the Materials

Optimize the efficiency of briquette production by using a wood hammer mill machine to shred the dried agricultural wastes into smaller pieces. Breaking down the materials increases the surface area, facilitating better binding during briquette formation.

Step 3: Biomass briquettes making

This step requires the use of a sawdust briquette making machine to make biomass briquettes from the crushed biomass waste. This will facilitate the subsequent carbonization into briquettes.

Step 4: Carbonizing

Carbonization is the most important step in making charcoal briquettes. A sawdust briquette can be made into a more resistant charcoal briquette from a large scale biomass briquette in a carbonization furnace.

Step 6: Storage and Utilization

Once fully dried, store the briquettes in a cool, dry location away from direct sunlight. You can also use charcoal briquette packaging machine to package the dried charcoal briquettes. This makes it easy to sell. These charcoal briquettes are ideal for cooking and heating due to their reduced smoke emissions and sustainable nature, making them a reliable alternative to traditional charcoal.

Advantages of Charcoal Machinery:

Investing in charcoal machines presents numerous benefits:

- Enhanced Efficiency: Wood charcoal machines automate the briquette production process, saving time and labor costs.

- Uniform Quality: These machines ensure consistent size and shape, leading to even burning and reliable results.

- Exceptional Durability: High-pressure briquette formation in these machines results in stronger and longer-lasting briquettes.

- Waste Minimization: Wood charcoal machines accommodate a variety of agricultural wastes, contributing to waste reduction and environmental preservation.

By following these steps and leveraging the capabilities of wood charcoal machines, you can effectively transform common agricultural wastes into valuable charcoal briquettes. This sustainable practice not only addresses waste management concerns but also offers an eco-friendly energy source. As the world shifts towards greener alternatives, mastering the art of creating charcoal briquettes from agricultural wastes places you at the forefront of a more sustainable future.