Charcoal production line whole process introduction: from crushing to carbonization standard process

In the face of wood waste disposal problems or a desire to enter the field of environmental protection and energy, the charcoal production line has become the choice of more and more enterprises and individuals.

So, how does a standardized charcoal production line work? What are the key equipment components? What is the role of each link?

Charcoal production line process flow

Charcoal production is generally divided into the following main steps, each of which is equipped with appropriate and efficient equipment:

Raw material crushing: wood crusher

crushes raw materials, such as tree branches, straw, and waste wood, into 3-5mm granular materials, which are convenient for subsequent briquetting.

Material drying: drum dryer

reduces the moisture of raw material to 10-15%, improves the molding rate, and prevents smoke or cracks during the carbonization process.

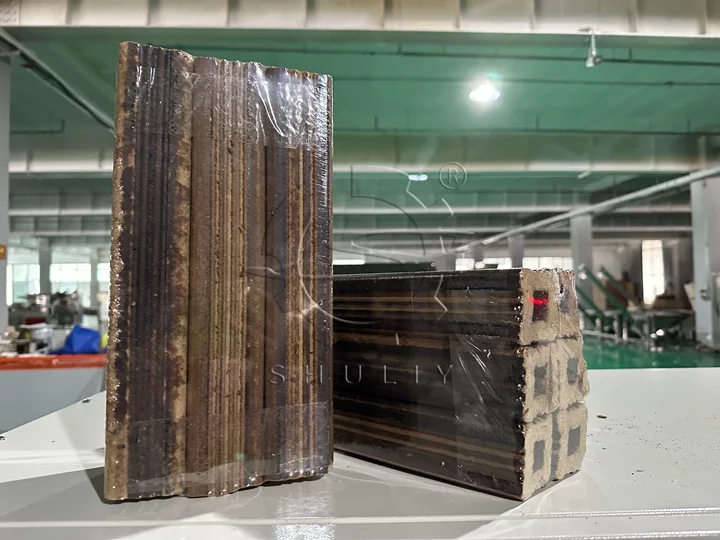

Stick molding: stick-making machine

adopts hydraulic pressure or screw extrusion to press the material into sticks of various shapes, such as strip, round, or hexagonal.

Continuous carbonization: a continuous carbonization furnace

utilizes high temperature and oxygen-free conditions to carbonize the molded charcoal sticks into mechanism charcoal. Meanwhile, it is equipped with a flue gas purification system, which is environmentally friendly.

Cooling and packing: cooling machine and packing machine

After cooling the charcoal sticks to room temperature, they will be weighed and packed automatically, which is convenient for sale and transportation.

Our equipment and advantageous features

Shuliy charcoal equipment is known for its high performance and stability, with specific advantages including:

Wood crusher

Crush wood chips, bamboo chips, straw, etc. into fine particles, large output, blade durable

Drum dryer

High thermal efficiency, adaptable to a variety of heat sources, such as firewood, natural gas, etc.

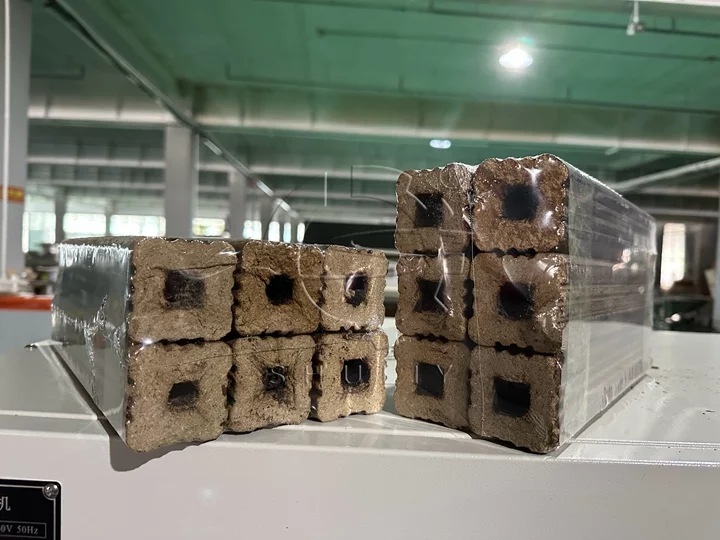

Sawdust briquetting machine

The molds can be replaced, support square, round, or hexagonal shape charcoal bar molding

Continuous carbonization furnace

Adopting high-temperature-resistant steel, it supports 24-hour continuous operation, and the carbonization rate reaches more than 95%.

Charcoal packaging machine

Automatic weighing, sealing, marking, saving labor, uniform appearance, easy storage, and transportation

Five core advantages of the equipment:

- High degree of automation, simple operation with one button start

- Support customized molds, voltage, and layout to meet the individual needs of global customers

- Energy-saving and environmentally friendly design, support for heat recovery and flue gas purification

- Stable operation and comprehensive after-sales service

- Modularized combination, flexible footprint, convenient layout

Creating an efficient, environmentally friendly, and intelligent charcoal plant

Whether you are an entrepreneur who has just entered the charcoal industry or an old customer who wants to expand production capacity, the one-stop mechanism charcoal production line provided by Shuliy can bring you a stable, environmentally friendly, and sustainable profit model.

If you have related needs, please feel free to contact us to get a free quote and technical program!