Efficient Compressed Wood Pallet Machine for Sale

Press Wood Pallet Machine | Wood Pallet Making Machine

Efficient Compressed Wood Pallet Machine for Sale

Press Wood Pallet Machine | Wood Pallet Making Machine

Features at a Glance

The compressed wood pallet machine automates the processing of raw material and compresses the wood under pressure and heat into wood pallets of the required size and thickness.

Compressed wood pallets are increasingly favored by the logistics industry and businesses due to their lightness, reusability, and environmental friendliness. Therefore, investing in a compressed wood pallet machine is a very wise choice.

What Is a Compressed Wood Pallet Machine?

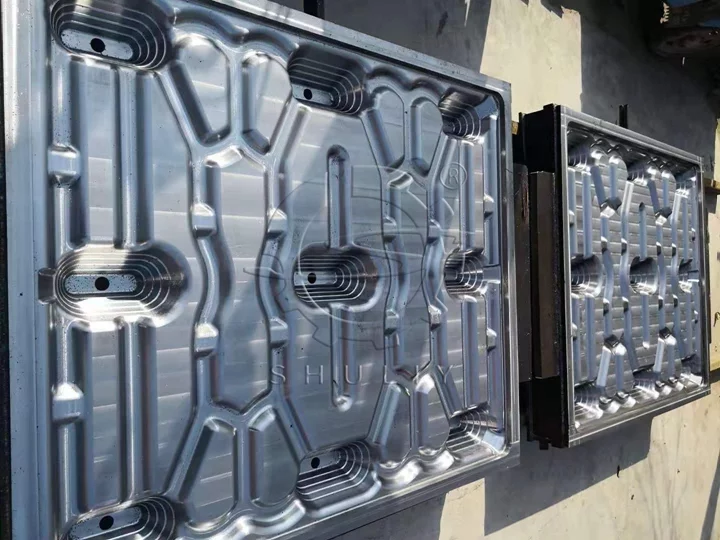

Compressed wood pallet machine is a machine used to manufacture compressed wood pallets. These machines make strong and durable wooden pallets by heating, compressing, and gluing raw materials such as wood chips, flakes, straws, rice husks, and waste wood at high temperatures. You can make compressed wood pallets of different sizes and shapes by changing molds

Advantages of Shuliy PressedWood Pallet Machine

- Independent hydraulic system.

- The operator can easily change the molds to produce different sizes and shapes of wooden pallets.

- Shuliy pressed wood pallet machine can complete the pressurization and molding process within 35 seconds.

- The high degree of automation. Workers only need to place the material in the machine. The compressed wood pallet will be popped out of the mold after it is made, and the worker can take the compressed wood pallet out easily.

- Customizable. We can customize the molds and so on according to customers’ needs.

- Consistent size of finished products. The compressed wood pallet machine can produce pallets with consistent size and quality.

Technical Data of the Compressed Wood Pallet Machine

| Model | SL-1000 |

| Capacity | Produce one pallet need 4-5 minutes(can control by yourself ) |

| Power | 15kw |

| Pressure | 1000t |

| Weight | 21000kg |

| Dimension | 1.9×1.3x4m |

Above are the parameters of one of our compressed wood pallet machines. Besides, we also have other styles of compressed wood pallet machines for sale. If you need, please feel free to contact us.

Compressed Wood Pallet Manufacturing Process

First, we need to collect wood pellets or wood sawdust. These raw materials are usually waste wood or by-products from wood processing. Of course, we also have a wood shredder that can pulverize large pieces of wood into smaller wood pellets.

Next, the raw materials are mixed with an adhesive designed to increase the hardness of the wooden pallets (the adhesive is usually an environmentally friendly urea-formaldehyde resin glue).

The mixture is then conveyed into the mold of the wood pallet press machine. Once the material is placed in the mold, the machine applies high pressure and temperature to it. This process allows the wood particles to be compressed and bonded, finally forming the shape of the compressed wood pallet.

The formed wood pallet usually requires a period of curing and cooling to ensure it is structurally sound. If required, the molded compressed wood pallet can be trimmed to ensure it meets specifications and quality requirements.

Types of Compressed Wood Pallet Making Machine

Compressed wood pallet making machines can be categorized into several types depending on their working principle, production capacity, and production scale:

Hot Press Wood Pallet Machine

This type of machine utilizes a high-temperature and high-pressure process to press and bond wood particles or chips into the shape of a pallet. The machine is heated and then high pressure is applied to promote bonding between the wood particles and to form a strong pallet structure after curing.

Cold Press Wood Pallet Machine

Unlike the hot press type, the cold press machine applies pressure and adhesive at a lower temperature to bind the wood particles to form the pallet. This type of machine usually takes longer to cure the wood particles.

Fully Automatic Wood Pallet Production Line

These machines automate multiple process steps such as raw material handling, mixing, molding, compression, and cooling. They offer higher capacity and efficiency and are capable of producing large quantities of compressed wood pallets continuously.

Customized Wood Pallet Machine

Some machines can be customized to produce compressed wood pallets of a specific size, shape, or material.

Compressed Wood Pallet Vs Traditional Wood Pallet

Environmentally friendly and sustainable

Compressed wood pallets are made using waste wood or wood pellets through recycling and reuse. This helps to reduce wood waste.

Weight and lightness

Compressed wood pallets made by compressed wood pallet machines are typically lighter than traditional wood pallets, which makes them easier to handle, stack, and transport while reducing transportation costs.

Durability and Stability

Although compressed wood pallets are lighter, their compressed wood construction makes them still highly durable and stable, able to withstand the weight and stress of cargo.

Customization and Consistency

The manufacturing process for compressed wood pallets can be customized to meet different sizes and requirements. In contrast, traditional wood pallets may vary in size and quality.

Hygiene and safety

Compressed wood pallets made by compressed wood pallet machines are often treated to be free of hazardous substances and are less likely to harbor bacteria, helping to keep goods sanitary and safe.

Raw Materials for Making Compressed Wood Pallets

Common types of wood used to make compressed wood pallets include pine, alder, oak, birch, fir, and poplar. Other wood fibers are also used as raw materials for compressed wood pallets. These fibers can come from waste paper, fiberboard, wood pulp, or other wood processing by-products. For the wood particles or wood fibers to bond tightly, it is often necessary to add some adhesive, such as phenolic resins, epoxy resins, or polyurethanes, to facilitate the bonding between the particles.

What Is the Price of a Press Wood Pallet Machine?

The price of press wood pallet machines varies depending on factors such as manufacturer, model, production capacity, and features.

Generally, these machines come in a wide range of prices and can cost anywhere from a few thousand dollars to hundreds of thousands of dollars. Low-end and smaller compressed wood pallet machines may cost around a few thousand to ten thousand dollars, while high-end, high-capacity, or fully automated machines may cost hundreds of thousands of dollars.

The capacity of the machine, the level of automation, the production specifications, as well as the brand and manufacturer will all have an impact on the price. If you want to know the exact price of a compressed wood pallet machine feel free to contact us. Our sales will contact you the first time and send you a quotation.

Hot Product

Rotary Sawdust Dryer Machine | Sawdust Drying Machine

The rotary drum sawdust dryer machine is a…

Horizontal Band Saw Mill

Horizontal band saw mill is a type of…

Disc Saw for Wood Cutting

Shuliy's disc saw machine can handle many types…

Horizontal Charcoal Furnace

Discover our efficient, eco-friendly horizontal charcoal furnace. Perfect…

Comprehensive Crusher for Crushing Pallet, Wood Material

Comprehensive crusher is a machine capable of crushing…

Shisha Charcoal Machine for Making Hookah Charcoal

Shisha charcoal machine is specifically designed to compress…

Vertical Bandsaw Mill for Wood Processing Plant

Vertical bandsaw mill is a type of sawmill…

Carbonization Furnace for Charcoal Making

Three different types of carbonization furnaces are used…

BBQ Charcoal Briquettes Machine

By changing molds, our BBQ charcoal briquettes machine…