Disc Saw for Wood Cutting

Table Saw with Sliding Table | Sliding Table Saws

Disc Saw for Wood Cutting

Table Saw with Sliding Table | Sliding Table Saws

Features at a Glance

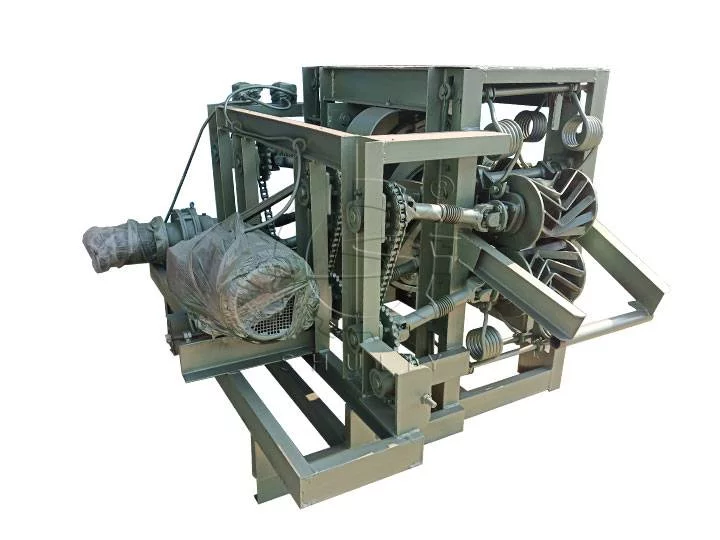

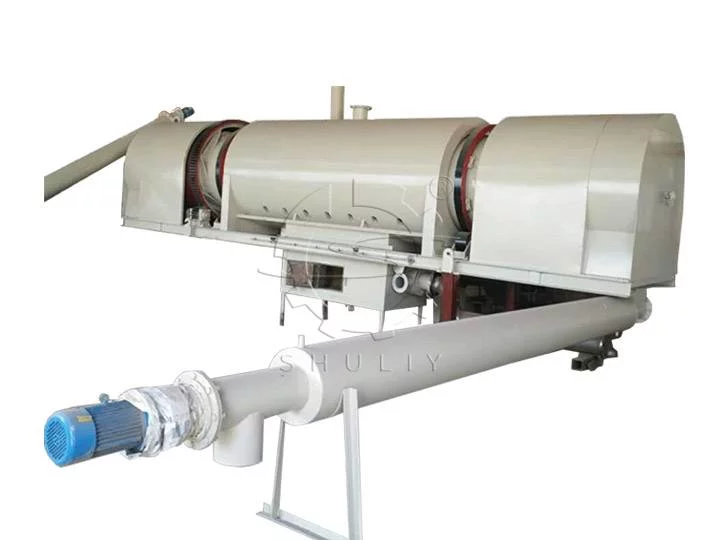

The disc saw is mainly used for sawing logs, square logs and other woods by precisely cutting them to the required size. The design of the sliding table saw allows the user to easily move the work on the sliding table, thus increasing the precision of the cut and the efficiency of the work. The type of equipment is widely used in the wood processing industry, furniture manufacturing and construction woodworking.

Application of Disc Saw

The wood sawmill machine can handle a variety of wood such as logs, square logs, wood segments, etc., and the diameter of the wood should be less than 50 cm.

- Furniture Manufacturing. Used for sawing round logs into lumber or squares for making furniture components.

- Construction Woodworking. Used for sawing round logs into sizes required for construction, such as beams, posts, etc..

- Woodworking shop. Used for a variety of woodworking tasks to increase efficiency.

- Woodworking Plant. Used for large scale wood sawing operations in large wood processing plants.

Features of Automatic Sawmill Machine

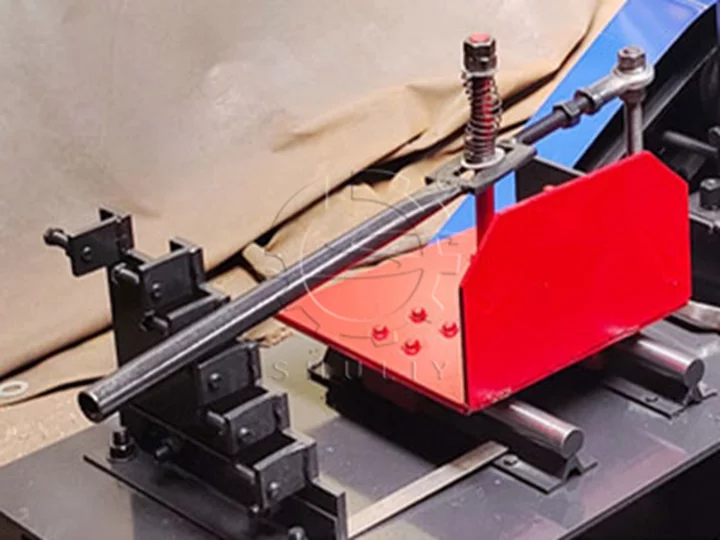

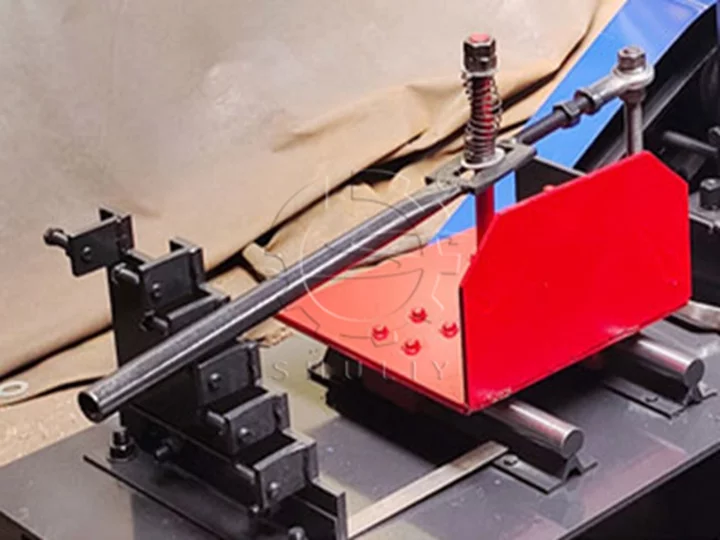

- Accurate and efficient. Ensure the accuracy of sawing dimensions by precise measuring and locking device. It not only greatly reduces the time of manual operation, but also cuts accurately.

- Cutting thickness can be adjusted. Customers can adjust the thickness of cutting according to their own needs.

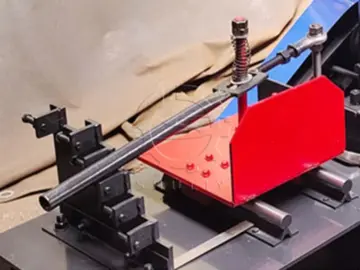

- Fixed gripping hook. After loading the material, the board is automatically pressed firmly by four sets of manual devices, and the wood is not easy to shake when cutting, and the cutting is even.

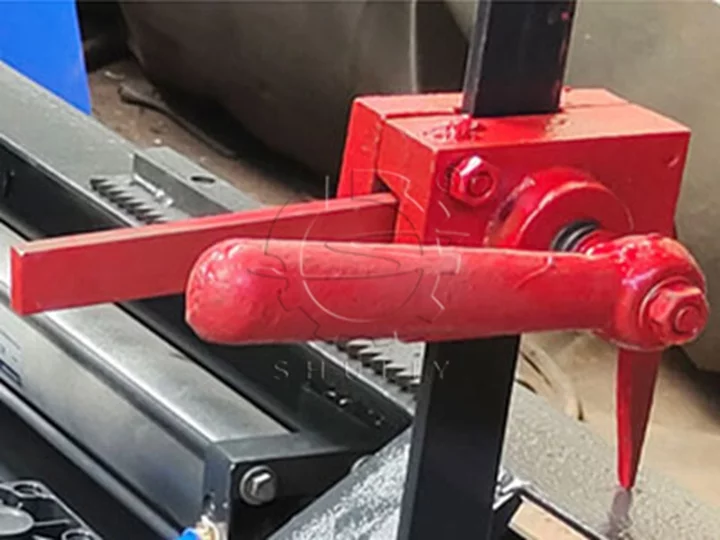

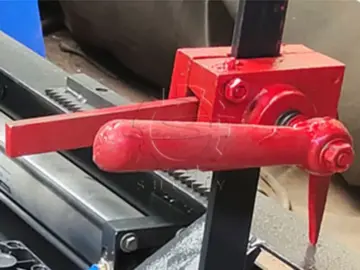

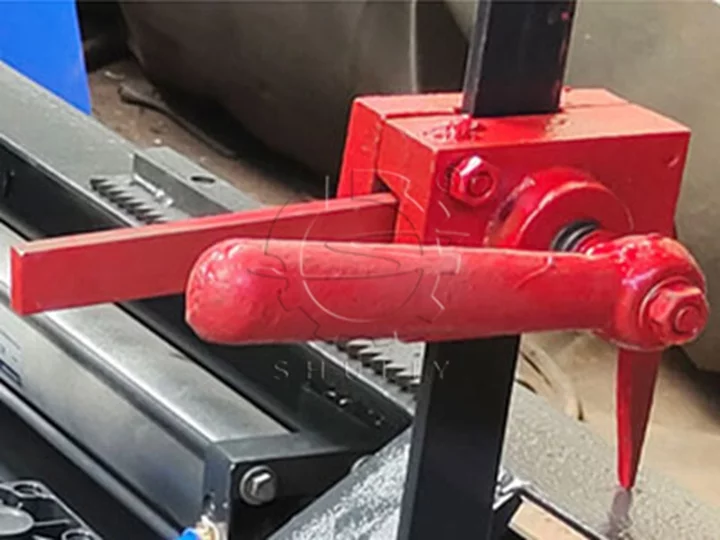

- Adjustable hand crank. Customers can adjust the hand crank to make the cutting more accurate.

- Mobile pulley. The equipment is stable and not easy to shake, and customers can also configure mobile pulleys for mobile operation.

- Simple operation. Equipment structure is simple, easy to start, no need for professional master, one person can operate.

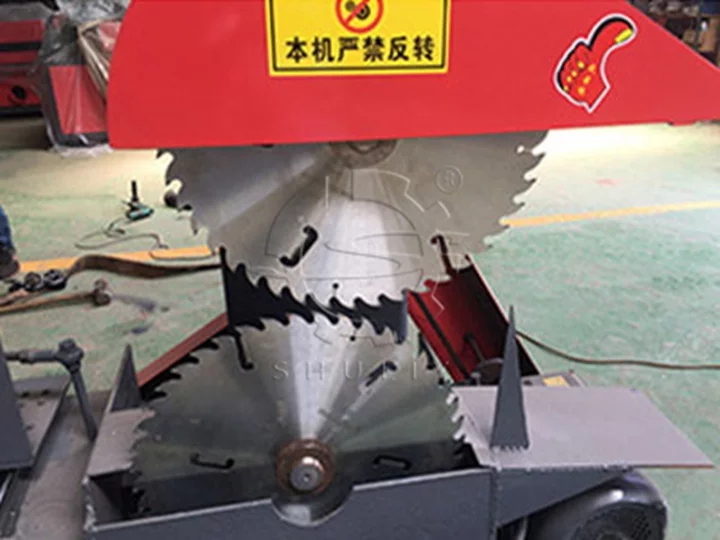

Advantages of Sliding Table Saw‘s Blades

Disc saw’s blades of Shuliy are made of alloy steel, which is sharp and not easy to deform, and has a long service life. Moreover, the equipment adopts the upper and lower rotation axis synchronized steering cutting, the two saw blades interact with each other, the cutting is strong and powerful, the cutting surface effect is smooth and flat.

And if the blades are blunt, damaged, etc., you can choose to replace the blades or use with a sharpener to improve cutting efficiency.

Sliding Table Saws for Sale

| Model | SL-300 | SL-400 | SL-500 |

| Motor power | 7.5kw*2 | 11+7.5kw | 11kw*2 |

| Dimension | 8000X1600X1600mm | 8000X1600X1600mm | 8000X1600X1600mm |

| Max sawing wood length | 4000mm | 4000mm | 4000mm |

| Max sawing wood thickness | 3000mm | 4000mm | 5000mm |

| Weight | 750kg | 750kg | 750kg |

Besides the above models, we have other models for sale. If you are interested, you can contact us for more information. We can also customize the equipment to meet your individual needs.

Wood Sawmill Machine Price

The sawmill machine price varies depending on various factors such as brand, specification, function, automation degree, material and manufacturing process. The general bandsaw wood mill machines’ price may range from several hundred dollars to several thousand dollars.

If you want to know more about sliding table saw price, detailed information, after-sales service, please contact us at any time. We can customize more suitable equipment for you according to your handling capacity, , budget and other aspects.

Bandsaw Mill Parts

The main structure of the table saw with sliding table includes saw blade, push table mechanism, sawing control system, saw blade lifting and tilting device, motor, safety device.

The length of disc saw for wood can be customized according to your needs. And the linear guide rail can strongly ensure that the push table moves in the right direction, keeping the straightness and uniformity of sawing.

Workflow of Bandsaw Wood Mill

Prepare Material

You need to choose suitable materials and adjust the height and angle of the saw blades according to your cutting needs to ensure the thickness of the cut. Then, place the wood to be cut on the sliding saw table to ensure it which is smooth and neat.

Cutting

Start the motor and push the small bandsaw mill slowly and evenly so that the wood is cut through the saw blade. At this point, the operator needs to keep his hands at a safe distance to ensure the stability of the operation. When the sawing is complete, turn off the motor and remove the sawed lumber.

Repeat

Continue to place new wood and repeat the sawing process.

Three Types of Sliding Table Saws

Disc Saw

Disc cutter saw cuts logs by placing them on a pusher table and then pushing them through a fixed saw blade. The cutting process is relatively simple and suitable for small mills and primary processing. Lumber bandsaw mill is mainly used to process logs up to 50 cm in diameter.

Vertical Saw Mill

Saw band of vertical saw mill is installed vertically. The cutting process runs smoothly and provides high cutting accuracy and flexibility. It is mainly used for processing maximum diameter of 80 cm-100 cm.

Horizontal Band Saw Mill

Saw band of horizontal timber band saw runs in a horizontal position and the wood is pushed towards the band by a pusher. It is mainly used to handle maximum diameters of 150 cm-250 cm, and it is suitable for medium-sized and large-sized wood processing companies that handle larger or thicker timber.

Vertical Bandsaw Mill for Wood Processing Plant

Vertical bandsaw mill, also known as a vertical band saw…

Horizontal Band Saw Mill

Horizontal band saw mill is a type of sawmill designed…

Hot Product

Carbonization Furnace for Charcoal Making

Three different types of carbonization furnaces are used…

Continuous Carbonizing Machine for Rice Husk, Sawdust, Bamboo

Continuous carbonizing machine is a kind of equipment…

BBQ Charcoal Packing Machine | Quantitative Packing Machine

BBQ charcoal packing machines are specialized equipment designed…

Vertical Bandsaw Mill for Wood Processing Plant

Vertical bandsaw mill is a type of sawmill…

Animal Feed Pellet Machine

Animal feed pellet machine can be used in…

Wood Hammer Mill Machine for Crushing Wood

Shuliy wood hammer mill is equipped with an…

Efficient Compressed Wood Pallet Machine for Sale

Shuliy's compressed wood pallet machine is equipped with…

Disc Wood Chipper for Log Chips Production

Disc wood chipper is a type of machine…

Hoisting Carbonizer Machine

Hoisting carbonizer machine is a equipment make charcoal…