How to Press Durable, Long-Burning BBQ Charcoal Briquettes?

Have you ever been troubled by the charcoal briquettes you produce? They are not hard enough, burn too quickly, and produce a lot of smoke and ash. These problems not only affect the reputation of your products but also directly erode your profits.

The core of the problem often lies not in the charcoal powder raw materials, but in whether you are using the correct molding technology.

Why are your charcoal briquettes “soft and don’t burn well”?

To solve the problem, we must first understand its root cause. The hardness and burning time of a high-quality charcoal ball mainly depend on its density.

The higher the density, the more carbon content per unit volume, and the harder the charcoal ball will be. It will also release heat more steadily and for a longer time when burning.

Three key factors lead to insufficient density in charcoal balls:

- Uneven mixing: the charcoal powder and binder are not thoroughly and evenly mixed.

- Inappropriate humidity: raw materials that are too dry or too wet cannot achieve the optimal forming state.

- Insufficient pressure: this is the most critical point. Without applying sufficient and sustained high pressure, carbon powder particles cannot bond tightly together, resulting in numerous internal voids and a naturally loose structure.

Charcoal balls produced using manual or simple equipment inevitably encounter all of the above issues precisely because they cannot guarantee consistent high pressure.

Shuliy professional BBQ charcoal briquettes machine

Our professional carbon ball machine is specifically designed to address the core issue of “pressure.” Its operating principle is both precise and powerful:

- Forced feeding: wet carbon powder, precisely mixed and stirred, is fed through the feed port into the space between two counter-rotating rollers.

- High-pressure compression: the surfaces of the two rollers are covered with uniformly shaped ball-shaped molds. As the rollers rotate, they exert immense linear pressure to force the carbon powder into the ball-shaped cavities.

- Instant forming: under this immense pressure, the carbon powder particles are tightly compressed into high-density carbon balls.

- Automatic demolding: as the rollers continue to rotate, the formed carbon balls automatically detach and enter the drying process.

This process is not only fast but also maintains constant pressure, ensuring that every charcoal ball meets the same quality standards. If you are interested in our charcoal ball machine, please contact us immediately.

The four core advantages of our charcoal ball machines

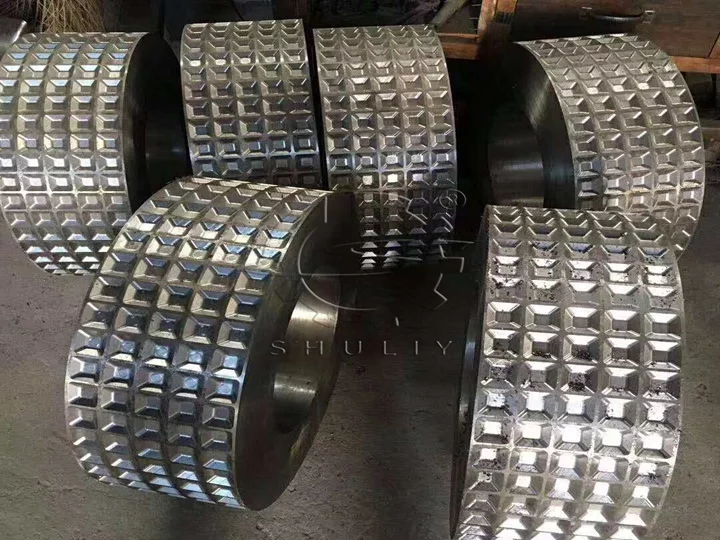

Super-strong, wear-resistant alloy rollers

We use 65Mn alloy steel for forging. This material has extremely high hardness and super-strong wear resistance.

Advantages: ensures that the breakage rate of carbon balls produced is reduced to a minimum. At the same time, the rollers have a longer service life, saving long-term maintenance costs.

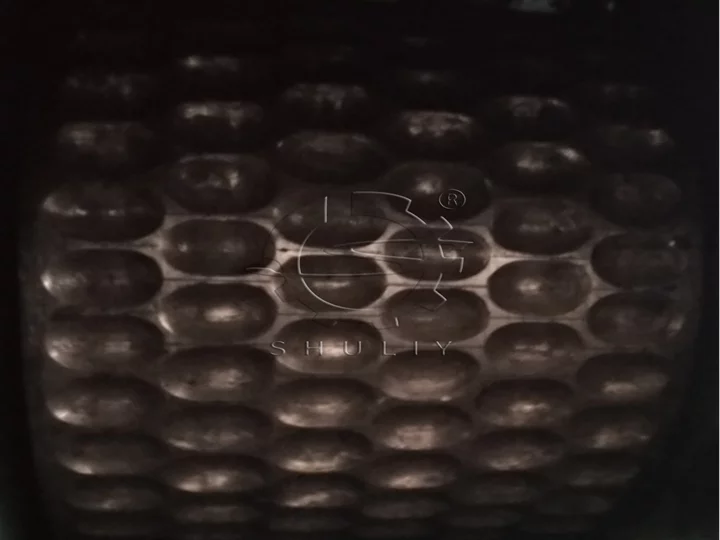

Flexible customization

We can customize various shapes of press roll molds according to your needs, such as pillow-shaped, oval, round, square, etc.

Advantages: unique shapes are the best brand calling card, allowing your products to be easily recognized on the shelves, achieving brand premium pricing, and escaping low-end competition.

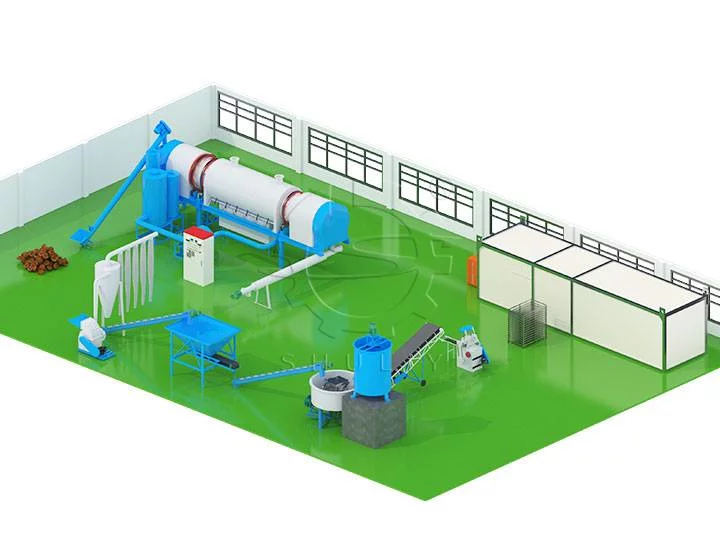

Highly efficient and comprehensive

We offer a wide range of models, from 1-2 tons/hour to 8-13 tons/hour, providing tailored solutions for both small start-up workshops and large-scale production plants.

Advantages: automated continuous production significantly reduces labor costs. You can select the most suitable production capacity based on your business development stage to maximize return on investment.

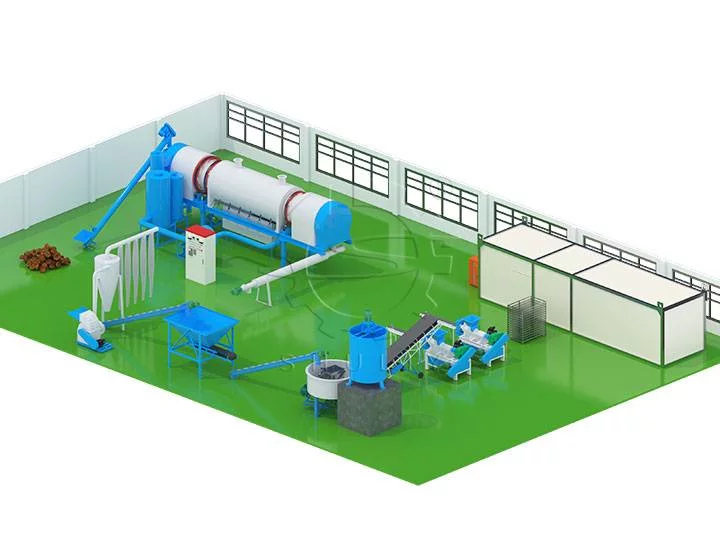

One-stop solution

We understand that a briquetting machine alone cannot complete the production process.

We provide a complete charcoal production line solution from raw materials to finished products, including: carbonization → charcoal powder crusher → mixer → charcoal ball molding machine → belt dryer.

Advantages: ensure seamless connection between each link, rapid production, and seize market opportunities.

Shuliy BBQ charcoal briquettes machine for sale

A professional Shuliy BBQ charcoal briquette machine is the cornerstone for improving product quality, establishing brand image, and achieving large-scale production.

It brings not only hard-burning charcoal briquettes, but also high production efficiency, differentiated market competitiveness, and a predictable, high-profit future.

Want to know which model and mold is best suited to your market? Contact our technical consultants immediately to get a complete production line quotation and solution tailored to your needs!