Sawdust Briquettes Production Line for Sale

Pini Kay Processing Plant | Sawdust Briquette Making Process

Sawdust Briquettes Production Line for Sale

Pini Kay Processing Plant | Sawdust Briquette Making Process

Features at a Glance

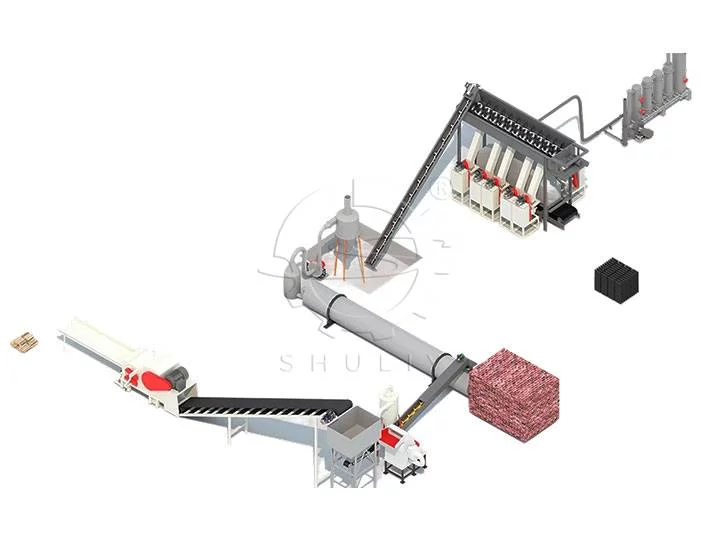

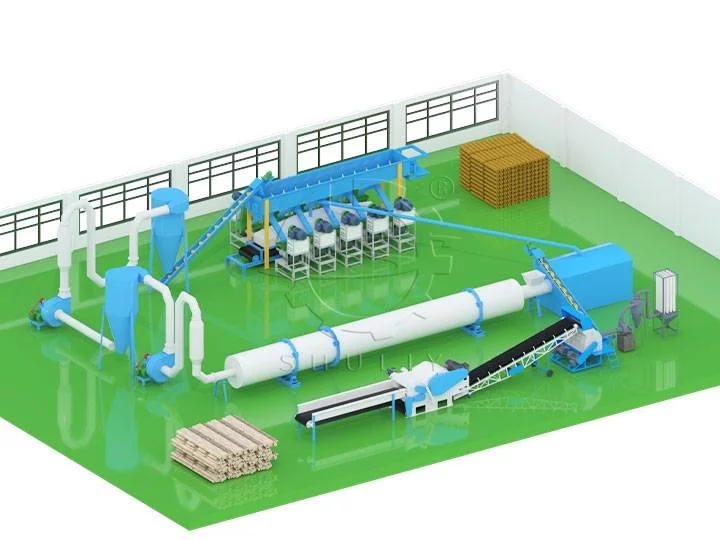

Sawdust briquettes production line is a set of sawdust briquettes making machine designed to convert sawdust, biomass, and other waste biomass materials into biomass briquettes. Briquettes are compressed blocks of biomass that can be used as a renewable and sustainable fuel source. Sawdust briquette manufacturer often uses a sawdust briquette machine to form dense and uniform biomass briquettes.

The Complete Sawdust Briquette Making Process

The sawdust briquettes production line operates through a series of well-orchestrated processes. Initially, the raw materials, such as sawdust, wood chips, straw, and agricultural residues, are collected and prepared. The materials undergo drying and size reduction to ensure optimal moisture content and particle size for efficient briquette production. Once ready, the materials are fed into a briquetting machine, which applies high pressure to compress them into dense and uniform briquettes. The briquetting machine may use mechanical or hydraulic systems to generate the required pressure.

Biomass Briquettes Finished Product Display

What Equipment Is Used in a Sawdust Briquettes Production Line?

A sawdust briquettes production line typically includes various essential equipment. The key components are:

Wood Crusher: To shred and reduce the size of the biomass materials, making them easier to handle and enhancing their drying capabilities. Various types of crushers, such as wood hammer mills and wood chippers, are commonly used in sawdust briquettes production lines.

Sawdust Drying machine: To reduce the moisture content of raw materials, ensuring that the briquetting process is efficient and the final product has good quality. There are different types of dryers, such as rotary drum sawdust dryers and belt type wood dryers, each with its advantages and applications.

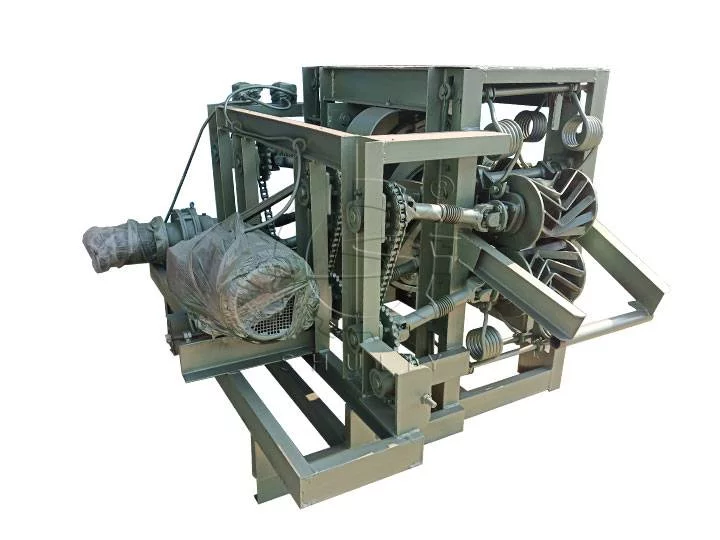

Sawdust Briquettes Extruder: The heart of the production line, the biomass briquette machine, applies high pressure to the prepared biomass materials, forming them into compact and consistent briquettes. At Shuliy Machinery, we have a high-quality Sawdust Briquettes Extruder Machine for sale.

Sawdust briquettes Packing machine: To package the briquettes for storage or transportation. The packed briquettes are then ready for distribution and use.

What Are the Raw Materials Used in Producing Biomass Briquettes?

Sawdust briquettes production utilizes a wide range of biomass waste materials. Common raw materials include sawdust, wood shavings, agricultural residues (like rice husks, and peanut shells), straw, and other forestry waste. The availability of raw materials varies based on the geographical location and the specific production line’s requirements.

Is the Pini Kay Processing Plant Line Environmentally Friendly?

Yes, sawdust briquettes production lines are environmentally friendly and sustainable. These lines convert waste biomass materials into valuable energy sources, reducing the reliance on traditional fossil fuels. By using renewable biomass, the production line contributes to carbon emission reduction and promotes a circular economy by utilizing waste materials effectively.

Sawdust briquettes have several environmental benefits. Firstly, they utilize biomass waste that would otherwise decompose and release greenhouse gases. By converting this waste into briquettes, the production line prevents methane emissions and helps reduce the overall carbon footprint. Secondly, using sawdust briquettes as a fuel source reduces the demand for fossil fuels, leading to decreased dependence on non-renewable resources and reduced greenhouse gas emissions during their extraction and combustion.

What Is the Cost and ROI of Setting up a Sawdust Briquettes Production Line?

The cost of setting up a sawdust briquettes production line can vary depending on the scale of the operation, location, and equipment choices. Initial investments may include acquiring biomass briquetting machines, sawdust drying equipment, wood crushers, and packing machines. The cost of raw materials, labor, and land also contributes to the overall setup cost.

The return on investment (ROI) of a sawdust briquettes production line can be promising. With the increasing demand for eco-friendly energy alternatives, the market for sawdust briquettes is expanding. Additionally, producing briquettes from waste biomass materials can lead to cost savings in waste management, as it reduces disposal costs for sawdust and other agricultural residues.

The ROI is influenced by factors such as production capacity, market demand, production efficiency, and the cost of raw materials. Conducting a thorough feasibility study and market analysis before setting up the production line can help estimate potential ROI and ensure the venture’s economic viability.

Production Capacity of a Sawdust Briquettes Production Line

The production capacity of a sawdust briquettes production line can be customized based on the specific needs and available resources. Production lines can be designed for small-scale operations with lower output or larger commercial facilities capable of producing thousands of briquettes per hour.

Small-scale pini kay processing plant may have an hourly output ranging from a few hundred kilograms to one ton of briquettes, while large industrial facilities can produce several tons of briquettes per hour. The production capacity depends on the size and complexity of the briquetting machines, the efficiency of the drying and cooling systems, and the availability and processing capacity of the raw materials.

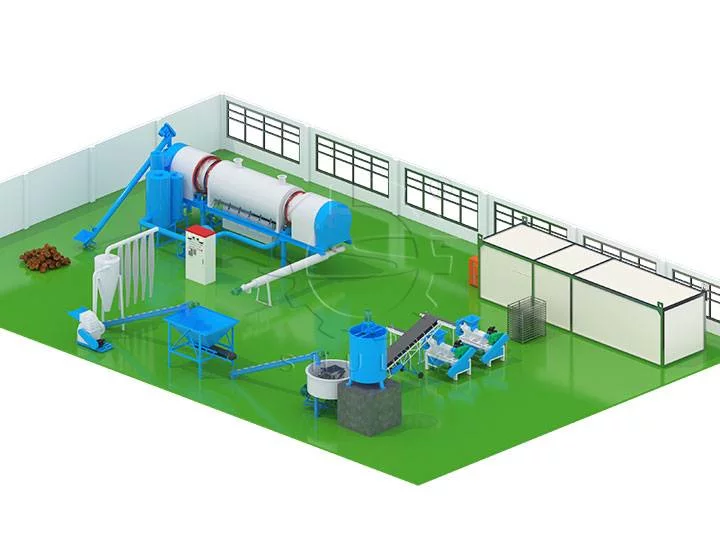

Do You Want to Get Charcoal Briquettes?

If you’ve got sawdust briquettes, then you’ll have no trouble getting charcoal briquettes. You just need to add a carbonization furnace to your sawdust briquettes production line. (This is charcoal briquettes production line) Then you put the sawdust briquettes in using a charcoal furnace and wait until the carbonization process is over to get high quality charcoal briquettes. At Shuliy Wood&Charcoal Machinery, we have two different styles of charcoal furnaces for you to choose from, they are vertical carbonization furnace and horizontal charcoal furnace. If necessary, please feel free to contact us.

Sawdust Briquette Machine for Making Pini Kay Briquettes

The sawdust briquette machine is a type of equipment used…

Sawdust Press Machine Shipped to Cambodia

In September 2021, a high-quality sawdust press machine embarked on…

Sawdust Briquette Machine for Sale in South Africa

In November 2021, a high-quality sawdust briquette machine embarked on…

Hot Product

Charcoal Briquettes Dryer for Charcoal Drying

The Shuliy charcoal briquettes dryer is a hot…

Charcoal Mixer Machine for Mixing Charcoal Powder, Water and Binder

Charcoal mixer machine utilize mechanisms such as rolling,…

Sawdust Briquette Machine for Making Pini Kay Briquettes

The briquettes produced by the Shuliy machine have…

Comprehensive Crusher for Crushing Pallet, Wood Material

Comprehensive crusher is a machine capable of crushing…

Disc Wood Chipper for Log Chips Production

Disc wood chipper is a type of machine…

Automatic Shrink Wrap Machine for Packing Charcoal Briquette

Automatic shrink wrap machine is a machine can…

Wood Crusher Machine for Biomass Waste

Wood crusher machine is a mechanical device used…

Shisha Charcoal Packing Machine

Shisha charcoal packing machine has efficient packaging speed…

Vertical Log Peeling Machine

Vertical log peeling machine is specifically designed to…