German clients utilize charcoal briquette machine to process metallurgical byproducts

Transforming byproducts from industrial production processes into reusable resources is key to achieving a circular economy and enhancing corporate profitability.

Our German client, a specialized metallurgical services company, has successfully processed coke fines and coal dust into standardized industrial fuel through the introduction of our charcoal briquette machine.

This initiative has enabled the value recovery of waste materials and ensured compliant disposal practices.

Client background and requirements

Our client is based in Germany’s industrial heartland, the Ruhr region. One of their primary businesses involves processing coke breeze and coal dust generated during production at large steel mills and foundries.

The client’s commercial objective is to establish an efficient resource recovery system: physically compressing these powdered materials into uniformly dense, standardized blocks. This enables their reuse as fuel or reducing agents in blast furnaces or smelting furnaces.

To achieve this, they require industrial-grade briquetting equipment capable of withstanding high-intensity operations and extreme pressure, featuring core components with exceptional wear resistance.

Tailor-made solutions

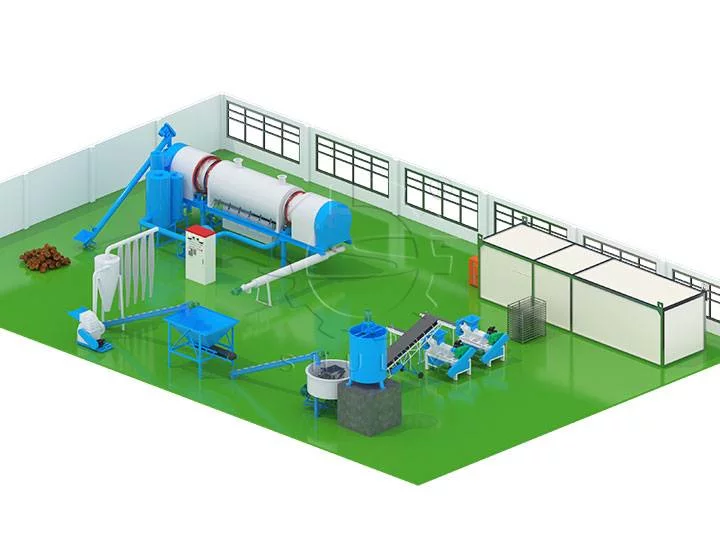

We provided our client with a complete powder forming system solution. During the project’s preliminary phase, we conducted physical property analysis on the coke powder samples supplied by the client and recommended suitable binder formulations and additive ratios based on the results.

We selected our coal briquetting machine for the client and configured auxiliary equipment, including a roller mill mixer and belt conveyor, to form an automated, streamlined production line.

Core advantages of our charcoal briquette machine

Addressing the client’s specialized requirements for processing high-hardness, high-abrasion materials, we highlighted our equipment’s core technological strengths:

High-strength double-roll compaction technology: the equipment’s core power stems from the forced compression of a pair of high-strength alloy rolls, generating immense line pressure to ensure loose powder is compacted into high-density briquettes.

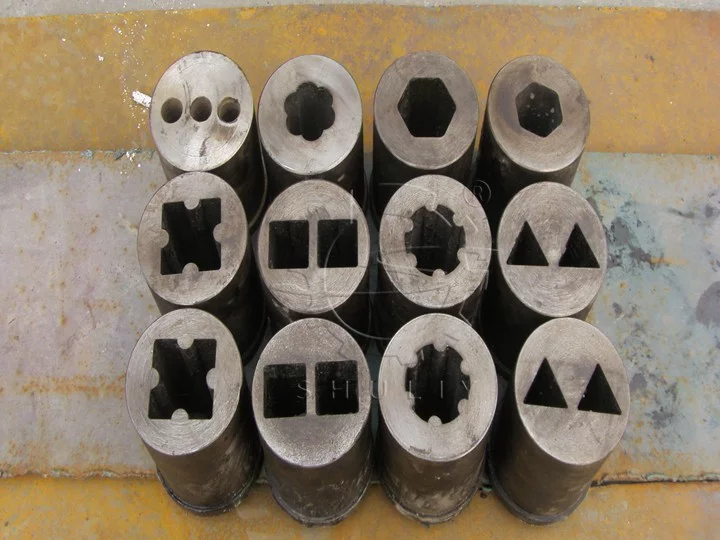

Precision-customized roller ball cavities: tailored to the client’s specific industrial application, we engineered pillow-shaped roller ball cavities. This customization ensures every briquette produced maintains uniform shape, dimensions, and weight.

Variable frequency drive with precision control: the main drive motor incorporates a variable frequency controller. Operators can precisely adjust roller speed in real-time.

Why choose Shuliy?

We conduct multiple test runs on the equipment and capture detailed videos and photos for customer verification. To ensure safe transportation, we implement protective measures such as outer film wrapping and reinforced wooden crates. We also support remote video inspections, guaranteeing the equipment is ready for immediate use upon arrival in Germany.

Beyond supplying high-quality equipment, our company offers comprehensive after-sales service. Upon arrival in Germany, our technicians provide full remote video guidance to assist clients with installation and commissioning, ensuring smooth production startup.

Positive feedback from customers

The customer has given high praise for the coal briquette machine after receiving it and putting it into operation. They stated that the equipment runs stably, the formed products burn thoroughly, and market feedback has been positive. Currently, the customer’s coal briquette products have successfully entered the German market, generating significant economic and social benefits.