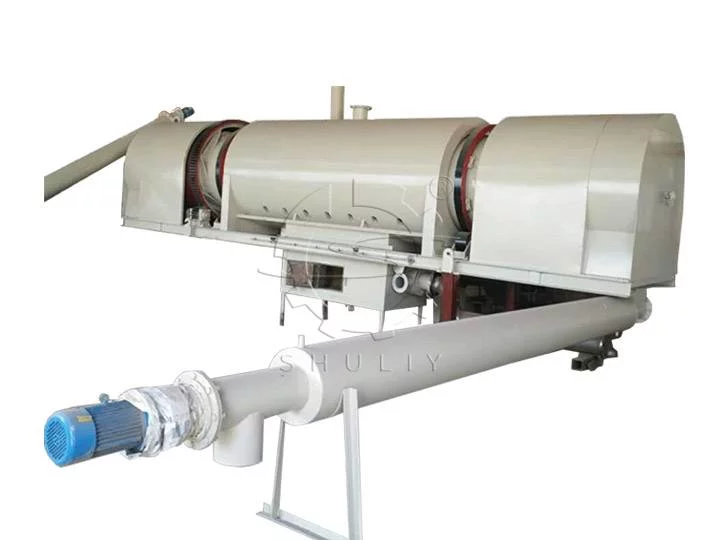

Continuous Carbonizing Machine and Drum Dryers Successfully Exported to Brazil

How can charcoal production be made more efficient and environmentally friendly? This was precisely the question posed by a client from Brazil. After thorough comparison, he ultimately chose our company’s integrated solution, combining a continuous carbonizing machine with a drum dryer.

Following the implementation of these two pieces of equipment, the client achieved a significant boost in production efficiency, realized a clean and stable carbonization process, and substantially reduced energy consumption.

Client Background and Requirements

Brazil, rich in forest resources, is a major producer and exporter of charcoal in South America. The client has long operated a charcoal processing plant, but the traditional earthen kiln carbonization method suffers from low efficiency, heavy smoke and dust, high energy consumption, and inconsistent product quality.

With increasingly stringent environmental policies, the client urgently requires an efficient, energy-saving, and sustainable carbonization system to replace the outdated kilns, enabling large-scale, clean production.

Advantages of Our Continuous Carbonizing Machine and Drum Dryers

Our company’s continuous carbonizing machine incorporates an automated feeding and discharging system with high-temperature pyrolysis technology, enabling continuous operation and high carbonization efficiency.

Concurrently, the drum dryer rapidly pre-dries raw materials such as wood chips and sawdust, ensuring stable moisture content in carbonization feedstock and thereby enhancing the final charcoal quality.

When used in tandem, these two pieces of equipment achieve fully automated production throughout the entire process, reducing labor requirements, minimizing energy consumption, and maximizing output.

What is Shuliy’s Suggestion?

During the project integration process, we customized adjustments based on the raw material characteristics of our Brazilian client (primarily eucalyptus wood chips and coconut shells). This included modifications to equipment dimensions, voltage specifications, and discharge port design to ensure stable local operation.

We also provided detailed installation instructions and operational videos to assist the client in completing commissioning more efficiently.

What Preparations Do We Make before Shipping?

During the shipping process, we conducted rigorous quality inspections and protective packaging for the equipment:

The machine’s exterior was covered with moisture-proof and rust-proof film, and the crate structure was reinforced to withstand long-distance ocean transport vibrations.

The customer also verified the packaging and machine condition via video inspection.

Customer Feedback

Upon arrival of the equipment, our technical personnel provided remote installation guidance and assisted the client in completing on-site commissioning. The client reported that the equipment operates smoothly with high energy efficiency, producing charcoal of consistent quality and low ash content.

The product has seen strong demand in the local market, significantly boosting the company’s profitability.