Honeycomb Charcoal Briquette Machine for Making Honercomb

Honeycomb Briquette Machine | Honeycomb Coal Press Machine

Honeycomb Charcoal Briquette Machine for Making Honercomb

Honeycomb Briquette Machine | Honeycomb Coal Press Machine

Features at a Glance

Honeycomb charcoal briquette machine, also known as a honeycomb coal press machine or honeycomb charcoal making machine, is a type of mechanical equipment used to produce honeycomb charcoal briquettes. It is commonly used in the coal industry and other industries where coal briquettes are used as a fuel source.

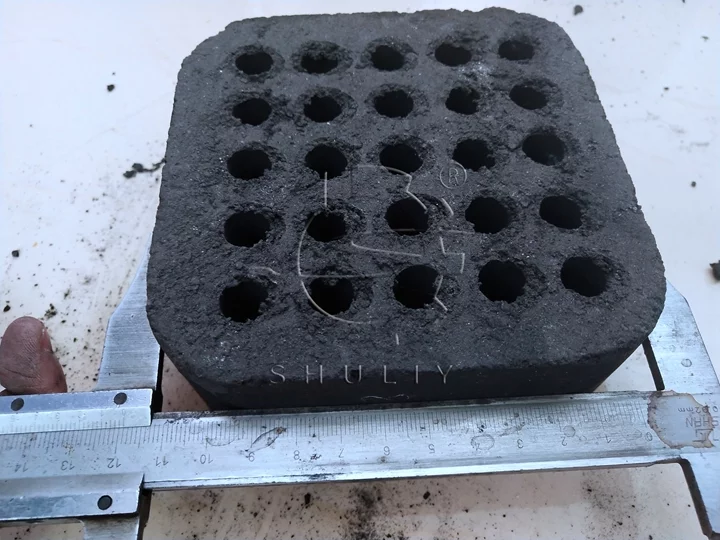

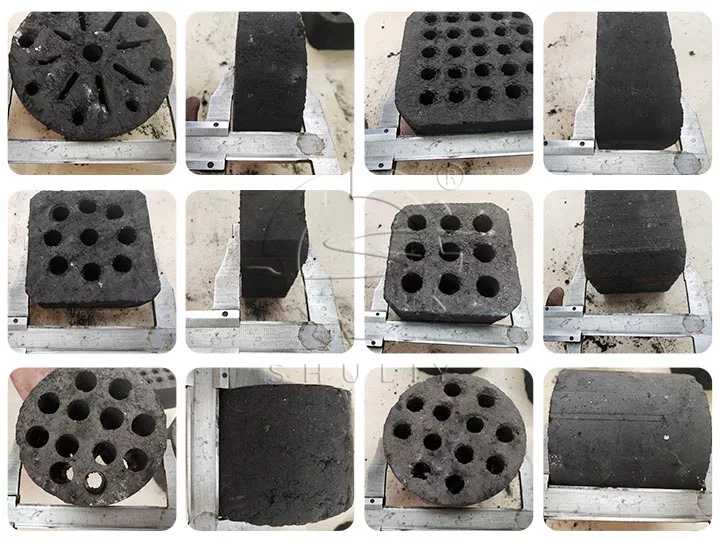

The honeycomb charcoal briquette machine utilizes a combination of pressure and binding materials to convert powdered coal/charcoal into briquettes with a honeycomb structure. The honeycomb shape allows for better airflow during combustion, ensuring efficient and even burning.

In our company, we also have other kinds of charcoal briquette machine for sale. If necessary, please feel free to contact us.

Working Principle of Honeycomb Charcoal Briquette Machine

The honeycomb briquette machine consists of several components, including a feeding hopper, a pressing chamber, a die, and a hydraulic system. Initially, the powdered coal or charcoal is fed into the machine’s hopper. Then, it is forced into the pressing chamber, where it is compressed under high pressure. The hydraulic system provides the necessary force to compress the material into the desired shape. This compression process forms the distinctive honeycomb structure of the briquettes, ensuring better airflow and efficient combustion.

Parameter of Honeycomb Coal Press Machine

| Model | Power | Maximum diameter of charcoal | Capacity | Weight |

| SL-120 | 4.5kw | 120mm | 6000Pcs/hour | 1.4t |

| SL-140 | 7.5kw | 140mm | 8000Pcs/hour | 1.5t |

| SL-160 | 11kw | 160mm | 10800Pcs/hour | 2t |

| SL-220 | 11kw | 220mm | 13500Pcs/hour | 3.8t |

The Capacity of the Honeycomb Charcoal Making Machine

The capacity of the Honeycomb Coal Making Machine varies depending on the model and design. Shuliy Machinery, a renowned Honeycomb Charcoal Press Machine manufacturer offers machines with different production capacities. Generally speaking, the machine can press 45 pcs/time. The specific capacity should be selected based on the desired production volume and requirements.

Features of Shuliy Honeycomb Charcoal Briquette Machine

Shuliy Honeycomb Charcoal Briquette Machines are equipped with several notable features:

- Robust Construction: The machines are built with high-quality materials to ensure durability and long service life.

- Adjustable Pressure: The hydraulic system allows for adjustable pressure settings, providing flexibility in briquette production.

- Easy Operation: The user-friendly design enables convenient and hassle-free operation, even for beginners.

- Energy Efficiency: The honeycomb briquette machine is designed to maximize energy efficiency and minimize waste during the briquette production process.

- Versatile Application: Shuliy machines can process various carbonaceous materials, including coal, charcoal, coke powder, carbon black, and biomass.

Application Ranges of Honeycomb Charcoal Press Machine

The honeycomb charcoal press machine finds extensive applications in multiple industries, including:

- Heating Industry: Honeycomb briquettes are widely used as a clean and efficient fuel source for heating applications in households, hotels, and commercial establishments.

- Cooking Industry: The honeycomb coal briquettes are ideal for use in stoves, grills, and barbecues, providing a consistent heat source for cooking and grilling.

- Metallurgical Industry: The honeycomb briquettes are used in metal smelting processes, such as iron and steel production, as a fuel source with enhanced combustion properties.

How to Operate the Honeycomb Briquette Machine Correctly?

To ensure optimal performance and longevity of the Honeycomb Coal Briquette Machine, follow these guidelines:

Preparing Raw Materials

Ensure that the coal or charcoal powder is finely ground and free of impurities.

Adjusting Pressure

Set the appropriate pressure level based on the desired briquette density and quality.

Maintaining Equipment

Regularly clean the machine to remove any residue and lubricate moving parts for smooth operation.

Safety Measures

Adhere to safety protocols and guidelines while operating the machine to prevent accidents.

Raw Materials for Honeycomb Production

Honeycomb briquettes can be made from various raw materials, including:

Coal: Bituminous coal, anthracite, lignite, or sub-bituminous coal can be used as the primary carbonaceous material.

Charcoal: High-quality charcoal obtained from wood or agricultural waste is another common raw material for honeycomb briquette production.

The Honeycomb Charcoal Briquette Machine is a reliable and efficient tool for producing honeycomb-shaped briquettes. As a versatile solution for clean and sustainable fuel, this machine plays a vital role in multiple industries, contributing to energy efficiency and environmental preservation. If you need this machine, please feel free to contact us.

Hot Product

Charcoal Briquette Machine for Bio Coal Briquettes Making

Charcoal briquette machine is a equipment designed to…

Efficient Compressed Wood Pallet Machine for Sale

Shuliy's compressed wood pallet machine is equipped with…

BBQ Charcoal Packing Machine | Quantitative Packing Machine

BBQ charcoal packing machines are specialized equipment designed…

Shisha Charcoal Machine for Making Hookah Charcoal

Shisha charcoal machine is specifically designed to compress…

Horizontal Band Saw Mill

Horizontal band saw mill is a type of…

Wood Hammer Mill Machine for Crushing Wood

Shuliy wood hammer mill is equipped with an…

Sawdust Briquette Machine for Making Pini Kay Briquettes

The briquettes produced by the Shuliy machine have…

Horizontal Charcoal Furnace

Discover our efficient, eco-friendly horizontal charcoal furnace. Perfect…

Disc Wood Chipper for Log Chips Production

Disc wood chipper is a type of machine…