BBQ Charcoal Packing Machine | Quantitative Packing Machine

BBQ Charcoal Packaging Machine

BBQ Charcoal Packing Machine | Quantitative Packing Machine

BBQ Charcoal Packaging Machine

Features at a Glance

BBQ charcoal packing machines are specialized equipment designed to automate the packaging process of BBQ charcoal products. This BBQ charcoal wrapping machine comes in various types and models, each catering to different production capacities and specific requirements. Whether it’s manual or fully automated, these packing machines excel in streamlining the packaging workflow, ensuring consistency, and optimizing overall efficiency. In Shuliy wood&charcoal machinery, we have a high-quality BBQ charcoal packing machine for sale.

Why Do We Need a BBQ Charcoal Packing Machine?

Grilling and barbecuing have become favorite pastimes for many, leading to a growing demand for high-quality BBQ charcoal. For manufacturers and suppliers in the BBQ charcoal industry, efficient and accurate packaging is crucial to meet the rising customer needs.

The Key Features of BBQ Charcoal Quantitative Packing Machine

- A reliable BBQ charcoal quantitative packing machine boasts essential features to enhance productivity and accuracy.

- Quantitative packing systems ensure precise measurements for each bag or container, avoiding wastage and maximizing profitability.

- The automation capabilities minimize the need for manual intervention, leading to reduced labor costs and faster packing times.

- With user-friendly interfaces, operators can easily monitor and control the packing process, improving the overall packaging precision.

Technical parameters of BBQ charcoal packaging machine

| Model | SL-BC-50F |

| Packaging speed | 4-6bags/min |

| Power | 380v/3kw |

| Weight range | 3-50kg |

| Application materials | Powdery or pellet materials |

| Packing accuracy | ±0.2% |

| Dimension | 650x1230x2050mm |

What Are the Advantages of Using BBQ Charcoal Packing Machines?

- Implementing BBQ charcoal packing machines can significantly benefit manufacturers and suppliers alike.

- By automating the packaging process, businesses experience improved productivity, enabling them to meet the growing demand efficiently.

- The consistent measurements achieved through the quantitative packing system translate into satisfied customers who receive reliable and accurately measured products.

- Moreover, reduced labor costs and increased packing speed lead to better cost-effectiveness for businesses.

Choosing the Right BBQ Charcoal Packaging Machine

Selecting the appropriate BBQ charcoal packaging machine for your specific needs is crucial for maximizing its benefits. Consider factors such as production capacity, packaging materials, and compatibility with your existing bbq charcoal production line. It’s essential to compare different models, weigh their features against your requirements, and assess the reputation of manufacturers or suppliers. By making an informed decision, you ensure a smooth integration of the packing machine into your operations.

Implementation and Integration

After choosing the ideal Barbecue charcoal wrapping machine, the next step is its seamless integration into your BBQ charcoal production processes. Proper training for employees on using the equipment safely and efficiently is vital for optimizing productivity and preventing downtime due to operational errors. Routine maintenance is equally important to ensure the machine operates at its best and remains reliable in the long run. This section offers valuable guidance on effective implementation and integration strategies.

Future Trends in BBQ Charcoal Packaging

As technology continues to advance, the future of BBQ charcoal packaging looks promising. Emerging innovations may introduce more sophisticated packing machines with even higher levels of automation and precision. These advancements are likely to redefine the industry’s standards and drive continuous improvements in the efficiency and sustainability of BBQ charcoal packaging.

BBQ charcoal packing machines are indispensable tools for manufacturers and suppliers in the charcoal industry. By embracing these automated solutions, businesses can enhance their productivity, meet customer demands with precision, and stay competitive in the market. If you need a high quality barbecue charcoal packaging machine, please feel free to contact Shuliy Wood&Charcoal Machinery. We will try our best to help you.

BBQ Charcoal Briquettes Machine

BBQ charcoal briquettes machine refers to an industrial device used…

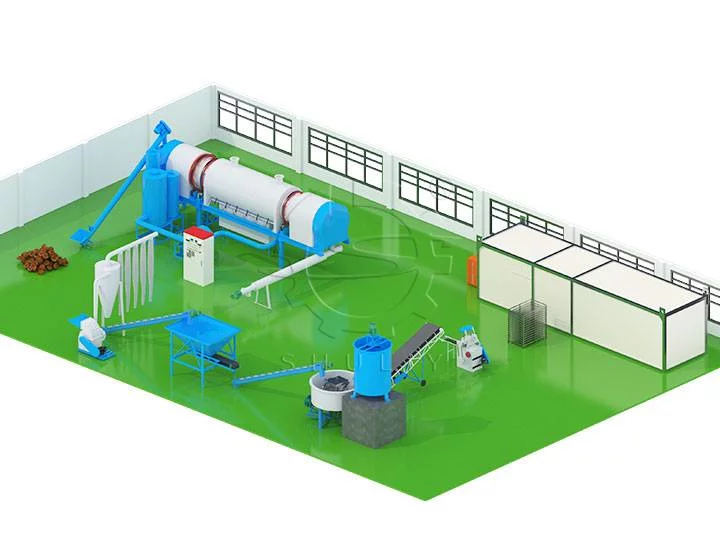

Barbecue Charcoal Production line

The barbecue charcoal production line represents a systematic assembly of…

BBQ Coal Press Machine for Sale in Mexico

In April 2023, a transformative shipment set out from Shuliy…

Shuliy Barbecue Charcoal Maker Machine Shipped to Thailand

In December 2022, a high-quality Barbecue Charcoal Maker Machine departed…

Raw Materials Suitable for Barbecue Charcoal Production and Selection Methods

Why is raw material selection critical to charcoal production? For…

How to Press Durable, Long-Burning BBQ Charcoal Briquettes?

Have you ever been troubled by the charcoal briquettes you…

How Does the Charcoal Ball Machine for Barbecuing Work?

Have you ever wondered how a pile of loose charcoal…

Hot Product

Coconut Shell Charcoal Making Machine for Turning Coconut Husk into Charcoal

We have three different types of coconut shell…

Drum Wood Chipper for Making Wood Chips

Drum wood chipper is a specialized equipment used…

Comprehensive Crusher for Crushing Pallet, Wood Material

Comprehensive crusher is a machine capable of crushing…

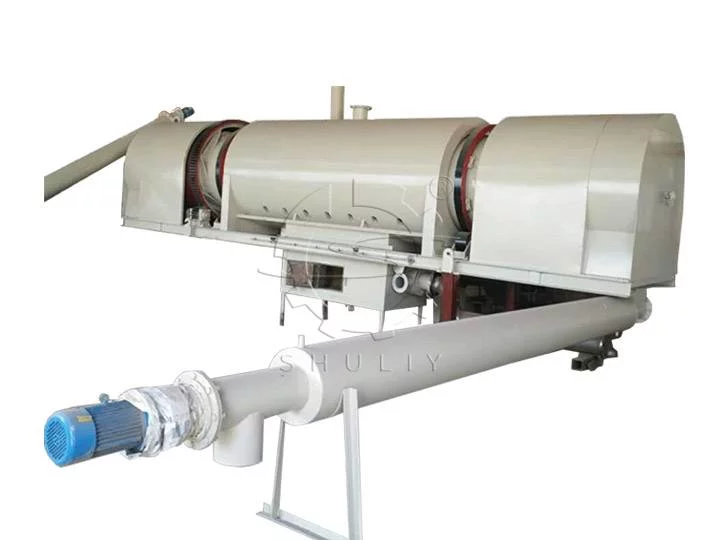

Continuous Carbonizing Machine for Rice Husk, Sawdust, Bamboo

Continuous carbonizing machine is a kind of equipment…

Charcoal Mixer Machine for Mixing Charcoal Powder, Water and Binder

Charcoal mixer machine utilize mechanisms such as rolling,…

Double Roller Wood Debarker Machine for Wood Processing

Double roller wood debarker machine can handle various…

Vertical Bandsaw Mill for Wood Processing Plant

Vertical bandsaw mill is a type of sawmill…

Animal Feed Pellet Machine

Animal feed pellet machine can be used in…

Charcoal Briquettes Dryer for Charcoal Drying

The Shuliy charcoal briquettes dryer is a hot…