Charcoal Briquette Machine for Bio Coal Briquettes Making

Charcoal Extruder Machine | Charcoal Briquette Making Machine

Charcoal Briquette Machine for Bio Coal Briquettes Making

Charcoal Extruder Machine | Charcoal Briquette Making Machine

Features at a Glance

Charcoal briquette machine, also known as a charcoal briquetting machine, is a piece of equipment designed to press charcoal powder into charcoal briquettes. Shuliy’s charcoal briquette machine presses charcoal powder into charcoal briquettes of various shapes and lengths.

These briquettes can be used as fuel for cooking, heating, and other industrial processes. In the charcoal briquettes production line, this machine is the key machine.

What Are the Types and Shapes of Briquettes?

Different types of charcoal brick machines can produce charcoal briquettes of different shapes and sizes. It depends on the design of the charcoal briquette machine and the shape of the mold.

- Square or Rectangular Charcoal Briquettes: This is the most common shape of charcoal briquettes and is suitable for grilling, heating, and general fuel purposes.

- Cylindrical Charcoal Briquettes: This shape of charcoal briquette is often used in certain stoves and thermal appliances.

- Pellet-shaped Charcoal Briquettes: This charcoal briquettes shape is more common in some specific applications, such as some hot pot or barbecue occasions.

- Irregular shape: Some charcoal briquette machines can make irregularly shaped charcoal briquettes according to user needs, and such charcoal briquettes may be suitable for special occasions.

When choosing a charcoal briquette making machine, users can choose the appropriate machine and mold according to the shape and size of the charcoal briquette they need. Different molds can easily realize different shapes of charcoal briquettes, enabling users to produce the most suitable charcoal briquettes according to their specific uses and needs.

How to Get Charcoal Briquette with Charcoal Briquette Machine?

Charcoal briquette machine is a machine that presses charcoal powder under high pressure into charcoal briquettes. During the compression process, the raw materials soften and bind together, forming sturdy and consistent briquettes of varying shapes and sizes.

Finally, an automatic charcoal cutter slices the charcoal briquettes into rectangular pieces of uniform length. This equipment ensures a sustainable and eco-friendly solution, as it transforms waste biomass into valuable energy sources. Charcoal briquettes made using the Shuliy charcoal briquette press machine will burn longer.

It is important to note that we need to add a certain amount of binder to the charcoal powder and keep the charcoal powder at a certain water content. This will make the produced charcoal briquette strong and unbreakable.

The Price of Charcoal Briquette Machine

The price of charcoal briquette machines varies based on factors such as production capacity, features, and model specifications. Different types of charcoal briquette machines cater to distinct needs and budgets. For precise pricing information, prospective buyers are encouraged to contact Shuliy Charcoal Machinery, a leading manufacturer offering a range of quality charcoal extruder machines at competitive prices.

The Types of Charcoal Briquette Making Machines

At Shuliy Charcoal Machinery, customers can choose from a diverse selection of charcoal briquette making machines, each designed to create briquettes with specific shapes. Among the available types are:

BBQ charcoal briquette extruder machine: This charcoal briquette extruder machine is ideal for producing spherical or round-shaped barbecue charcoal briquettes, commonly used for barbecues and cooking purposes.

| Model | SL-290-2 | SL-360-2 | SL-500-2 | SL-650-2 |

| Capacity(t/h) | 1-3 | 3-5 | 5-10 | 8-13 |

| Power(kw) | 5.5-7.5 | 7.5-11 | 22-30 | 37-55 |

| Spindle speed(r/min) | 12-15 | 12-15 | 12-15 | 10-13 |

| Dimension(m) | 1.6×1.2×1.4 | 2.1×1.3×1.76 | 2.6×1.75×2.1 | 3.42x2x2.2 |

Honeycomb Charcoal Briquette Press Machine: This charcoal briquette press machine forms briquettes in honeycomb or hexagonal shapes, suitable for various heating and industrial applications.

| Model | Power | Maximum diameter of charcoal | Capacity |

| SL-120 | 5.5kw | 120mm | 45 Pcs/time |

| SL-140 | 7.5kw | 140mm | 45 Pcs/time |

| SL-160 | 11kw | 160mm | 45 Pcs/time |

| SL-220 | 11kw | 220mm | 45 Pcs/time |

Shisha Charcoal Machine: Specialized in crafting high-quality hookah/shisha charcoal briquettes, this machine caters to the demands of the smoking industry.

| Size of the molds | Number of punching once | Number of punches per minute |

| 2cm*2cm*2cm cube | 90 | 3 |

| 2.5cm*2.5cm*2.5cm cube | 80 | 3 |

| Diameter 3cm round | 72 | 3 |

| Diameter 3.3cm round | 56 | 3 |

The Advantages of Charcoal Extruder Machine

The charcoal extruder machine offers numerous advantages, making it a preferred choice for biomass processing:

- Environmentally Friendly: By converting agricultural waste and other biomass materials into charcoal briquettes, this charcoal briquetting machine promotes eco-friendly practices and reduces waste.

- Efficient and Cost-Effective: The high-pressure compression process ensures efficient briquette production, maximizing the value obtained from biomass materials.

- Versatility: With different types of machines available, users can create various shapes and sizes of briquettes to suit specific applications.

- Cleaner Burning: Charcoal briquettes produce less smoke and ash compared to traditional wood or charcoal fuels, making them a cleaner option.

What Machine Is Used to Make Briquettes?

The machine used to make briquettes is known as the charcoal briquette machine. It effectively processes biomass charcoal powder and converts it into compact, uniform, and sturdy charcoal briquettes for energy use.

How to Start a Charcoal Briquettes Business?

If you want to start a coal briquetting plant, you need to follow these steps.

Research and Market Analysis

Understand the demand for charcoal briquettes in your target market and study the competition.

Business Plan

Create a comprehensive business plan outlining your goals, strategies, and financial projections.

Procure the Right Equipment

Contact reputable manufacturers like Shuliy Charcoal Machinery to acquire the appropriate charcoal briquette machine for your production needs.

Raw Materials

Secure is a steady supply of quality biomass materials suitable for briquette production. Materials

Marketing and Distribution

Develop effective marketing strategies to promote your product and establish distribution channels.

Is Charcoal Briquettes Profitable?

Yes, producing and selling charcoal briquettes can be a profitable venture, especially when considering the increasing demand for sustainable and clean energy sources. In addition, the profitability of the business depends on factors such as production efficiency, market demand, and cost management.

What Are Charcoal Briquettes Made Out Of?

Charcoal briquettes are made out of a combination of charcoal powder or fines and a binding agent with the help of the Charcoal Briquette Machine. The primary ingredients used to make charcoal briquettes include:

- Charcoal Powder/Fines: Charcoal powder, also known as charcoal dust or fines, is the main ingredient in the briquette-making process. It is typically obtained by grinding or crushing charcoal produced from various sources, such as wood, coconut shells, or other organic materials.

- Binding Agent: A binding agent is added to the charcoal powder to hold the briquette together and give it its shape. Common binding agents include starch (corn, cassava, or other plant-based starches), clay, or a mixture of both. The binding agent helps the charcoal particles stick together during the compaction process.

- Ignition Enhancers (Optional): Some manufacturers add ignition enhancers, such as sawdust or other flammable materials, to improve the briquette’s ease of ignition and initial burning.

- Additives (Optional): Depending on the desired properties, manufacturers may add other additives like borax, sodium nitrate, or limestone to enhance the burning characteristics or modify the final product.

Which Charcoal Burns the Longest?

The burning time of charcoal can vary depending on several factors, including its composition, size, and density. Generally, hardwood charcoal burns longer compared to softwood charcoal. Hardwood charcoals are made from dense wood varieties like oak, hickory, maple, or beech, which have a higher carbon content and produce a longer-lasting burn.

On the other hand, softwood charcoals, made from woods like pine or fir, tend to have a lower density and carbon content. Consequently, they burn faster and may not provide the same duration of heat as hardwood charcoal.

Lump charcoal, which consists of irregular chunks of charred wood, also tends to burn longer than briquettes. Lump charcoal is less processed and contains fewer additives, resulting in more natural and longer-lasting burns.

To maximize burning time and efficiency, it’s essential to select high-quality hardwood charcoal or lump charcoal, maintain proper airflow during burning, and use an appropriate grill or stove that allows for efficient heat retention. Additionally, using a charcoal chimney or other charcoal starters can help achieve an even longer burn.

Contact us

The charcoal briquette machine offers a sustainable solution for converting biomass materials into valuable fuel sources. With Shuliy Charcoal Machinery as a trusted manufacturer, interested individuals can explore a range of types and prices to meet their specific requirements. Starting a charcoal briquettes business can be a lucrative venture, contributing to a greener future while enjoying profitability in the process.

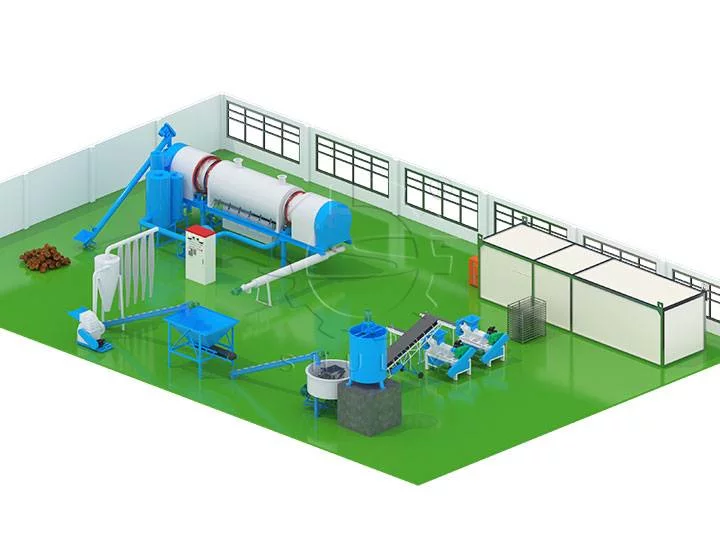

Charcoal Briquettes Production Line | Briquette Charcoal Plant

Charcoal briquettes production line is a set of equipment and…

Biomass Charcoal Briquettes Machine for Sale in Kenya

In the heart of East Africa lies the beautiful country…

Charcoal Briquette Extruder Machine Exported to Guatemala

In June 2021, Shuliy Charcoal & Wood Machinery proudly dispatched…

How to Make Charcoal Briquettes Burn Longer?

Charcoal briquettes are a popular choice for grilling and cooking…

Shuliy Charcoal Briquettes Machine for Sale in Philippines

In the picturesque archipelago of the Philippines, where the lush…

4 Different Kinds of Charcoal Briquette Press for Sale

If you're looking for the best charcoal briquette making machines…

Where to Buy Wood Charcoal Briquette Machine?

When it comes to procuring a high-quality wood charcoal briquette…

Shuliy Charcoal Briquettes Machine for Sale in the Philippines

In the heart of the Philippine archipelago, a story of…

Charcoal Briquette Machine in South Africa

In the vibrant landscape of South Africa, the demand for…

Hot Product

Double Roller Wood Debarker Machine for Wood Processing

Double roller wood debarker machine can handle various…

Disc Wood Chipper for Log Chips Production

Disc wood chipper is a type of machine…

Honeycomb Charcoal Briquette Machine for Making Honercomb

Honeycomb charcoal briquette machine, also known as a…

Vertical Bandsaw Mill for Wood Processing Plant

Vertical bandsaw mill is a type of sawmill…

Shisha Charcoal Machine for Making Hookah Charcoal

Shisha charcoal machine is specifically designed to compress…

Rotary Sawdust Dryer Machine | Sawdust Drying Machine

The rotary drum sawdust dryer machine is a…

Horizontal Band Saw Mill

Horizontal band saw mill is a type of…

BBQ Charcoal Packing Machine | Quantitative Packing Machine

BBQ charcoal packing machines are specialized equipment designed…

Automatic Shrink Wrap Machine for Packing Charcoal Briquette

Automatic shrink wrap machine is a machine can…