What are the core pieces of equipment in a complete charcoal briquette production line?

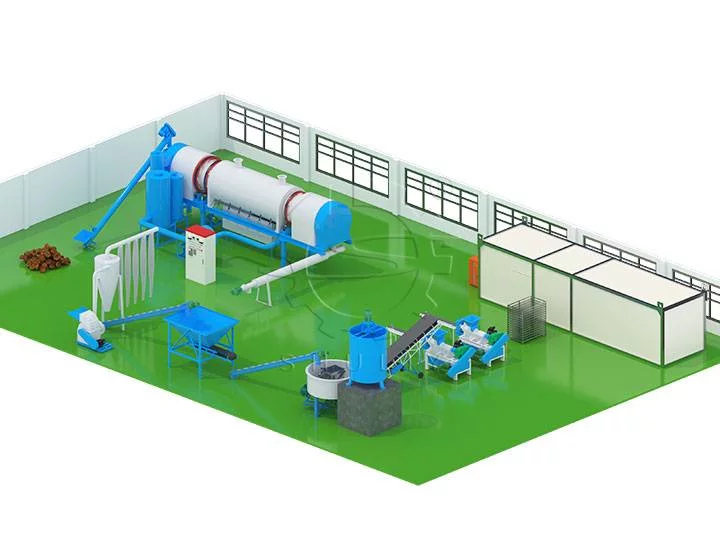

A common misconception is that you only need a single machine; in reality, a truly efficient and successful operation relies on a complete, integrated charcoal briquettes production line.

This charcoal briquette production line isn’t just a collection of equipment; it’s a synergistic process where each machine plays a vital role. Let’s walk through the five core machines that transform low-value charcoal dust into dense, long-burning briquettes that the market demands.

Carbonization furnace

Before you can make a charcoal briquette, you need high-quality charcoal. The carbonization furnace is where this transformation begins. It takes raw biomass—like wood logs, coconut shells, or bamboo—and converts it into charcoal through a high-temperature, low-oxygen process.

How it works:

The furnace heats the biomass, driving off moisture, wood vinegar, tar, and other impurities. What remains is a product with a very high carbon content. We offer various types, from hoisting carbonizer machines to advanced continuous carbonization machines for large-scale production.

This step is crucial for quality control. By creating your own charcoal, you ensure a pure, high-calorific-value raw material. This directly translates to a premium final briquette that burns hotter, longer, and with less smoke.

Charcoal crusher

The large, irregular chunks of charcoal from the furnace are not suitable for making briquettes directly. They must be crushed into a fine, consistent powder.

How it works:

The charcoal crusher uses high-speed rotating hammers to smash the charcoal chunks against a hardened inner lining. The resulting powder passes through a screen at the bottom to ensure every particle is below a specific size (typically 3-5mm).

Uniformity is key. A fine powder mixes more evenly with binders and water, which is essential for creating a strong, dense briquette. Without proper crushing, your final product will be weak, prone to breaking, and have inconsistent burning characteristics.

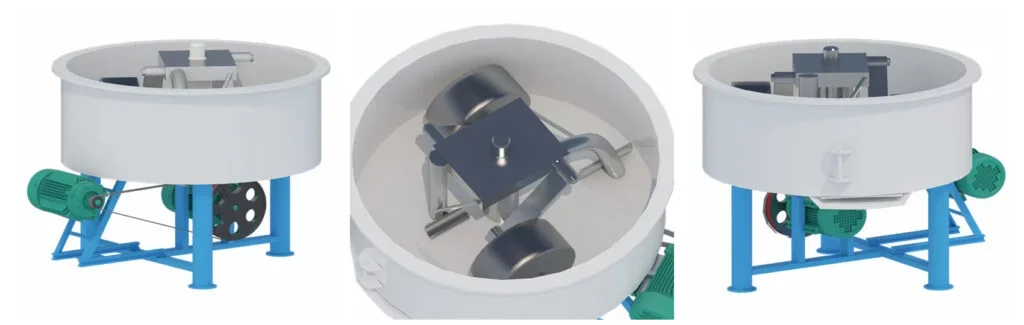

Charcoal mixer

The charcoal mixer is where the magic recipe comes together. The fine charcoal powder is mixed with a precise amount of water and a binder (like starch) to create a homogenous, moldable mixture.

How it works:

The charcoal powder, water, and binder are added to the mixer. Large rotating paddles or wheels thoroughly blend the materials, ensuring that every particle of charcoal is coated with the binding agent. This process increases the plasticity and stickiness of the mixture, preparing it for high-pressure molding.

A thorough mix is non-negotiable. It guarantees that your briquettes will be uniformly strong, preventing weak spots and fractures. It also ensures consistent combustion, giving your customers a reliable and predictable burning experience every time.

Charcoal briquette machine

The charcoal briquette machine is the central machine that takes the prepared mixture and, under immense pressure, forms it into the desired briquette shape.

How it works:

The homogenous mixture is fed into the briquette machine. Depending on the model, it uses mechanical presses, powerful rollers, or screw extrusion to compact the material into molds. This extreme pressure forces the particles together, creating a dense, solid briquette.

Density equals value. The high pressure creates briquettes that are not only hard to break but also burn significantly longer than natural charcoal. By offering various molds (e.g., pillow, square, hexagonal rod), you can also cater to different market preferences, from BBQ to industrial use.

Briquette dryer

The newly formed briquettes contain moisture from the mixing stage, making them soft and unsuitable for packaging or use. The final step is to dry them properly in the briquette dryer.

How it works:

The wet briquettes are placed onto a mesh belt and transported slowly through a long drying chamber. Controlled hot air circulates through the chamber, evenly removing the moisture without causing the briquettes to crack.

This final step is your quality guarantee. Proper drying ensures the briquettes reach their maximum hardness, preventing breakage during transport. It also makes them easy to ignite and ensures they burn efficiently. A dryer allows for continuous, year-round production, independent of weather conditions.

Shuliy charcoal briquette production line for sale

As you can see, each of these five machines is a critical link in the chain. Investing in a complete, integrated charcoal briquette production line from a single, reliable supplier ensures that all components work together seamlessly. This synergy results in higher efficiency, superior product quality, and ultimately, greater profitability for your business.

Ready to turn charcoal dust into a profitable enterprise? Contact our experts today, and we’ll help you design a complete production line tailored to your specific needs and raw materials!