Continuous Carbonizing Machine for Rice Husk, Sawdust, Bamboo

Continuous Carbonization Furnace | Biomass Carbonization Machine

Continuous Carbonizing Machine for Rice Husk, Sawdust, Bamboo

Continuous Carbonization Furnace | Biomass Carbonization Machine

Features at a Glance

Shuliy continuous carbonizing machine is a kind of equipment used for charring materials with biomass properties, such as wood, fruit shells, rice husks, and so on. This charring process is carried out in a continuous operation, ensuring high efficiency and high capacity.

Our continuous charcoal furnaces can convert raw materials with less than 20% moisture into a carbon-rich product, charcoal, through a process of heating and combustion.

The Feature of the Continuous Carbonization Furnace

- Versatility: Capable of processing a wide range of biomass materials, including wood chips, nut shells, agricultural residues, and more, with a diameter of up to 15 cm.

- Continuous Operation: Maintains an uninterrupted carbonization process, allowing for consistent and efficient production of carbon-rich products.

- Gas Utilization: This continuous charcoal carbonization furnace can capture and utilize gases produced during carbonization, potentially providing an additional energy source.

- Energy saving: The fan can re-direct the filtered combustible gases into the combustion cell for recirculating combustion.

- Safety Measures: Incorporates safety features to ensure secure operation, including temperature monitoring and emission controls.

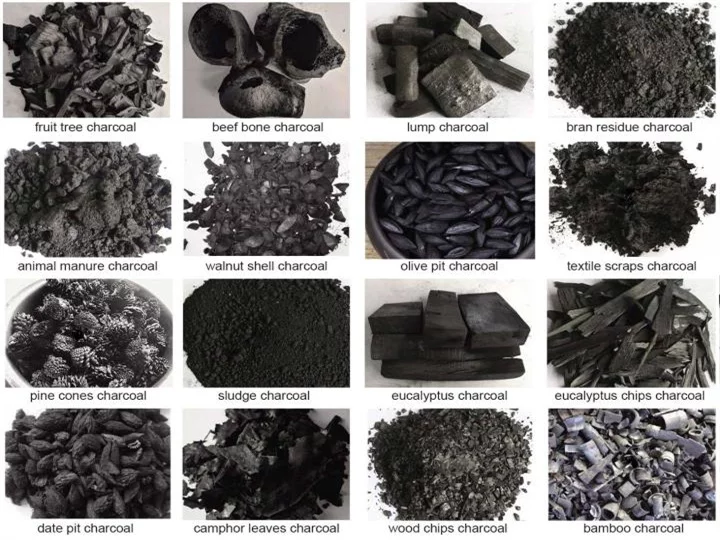

What Raw Material Can Be Put into the Continuous Carbonization Furnace?

The continuous carbonization furnace can carbonize peanut shells, sawdust, corn stalks, bagasse, tree branches, rice husks, bamboo shavings, sorghum stalks, sunflower seed shells, wine lees, corn cobs, sorghum stalks, coconut shells, apricot shells, peanut shells, coffee residue, cotton stalks, soybean stalks, yam grass, withered leaves, Chinese medicine dregs, hemp stalks, palm shells, and other materials with biomass properties.

It should be noted that the moisture of the raw material should be less than 20%. Moreover, the diameter of the raw material needs to be less than 15 centimeters.

Parameter of Continuous Carbonizing Machine

| Type | LT-800 | LT-1000 | LT-1200 |

| Capacity(kg/h) | 400-600 | 800-1000 | 1200-1500 |

| Fan Power(kw) | 5.5 | 5.5 | 5.5 |

| Main Power(kw) | 18.5 | 18.5 | 20 |

| Carbonization Temperature(℃) | 500-800 | 500-800 | 500-800 |

| Diameter(mm) | 800 | 1000 | 1200 |

In addition to these three hot-selling Continuous Carbonizing Machines, we have other models for sale. Please feel free to contact us for more information.

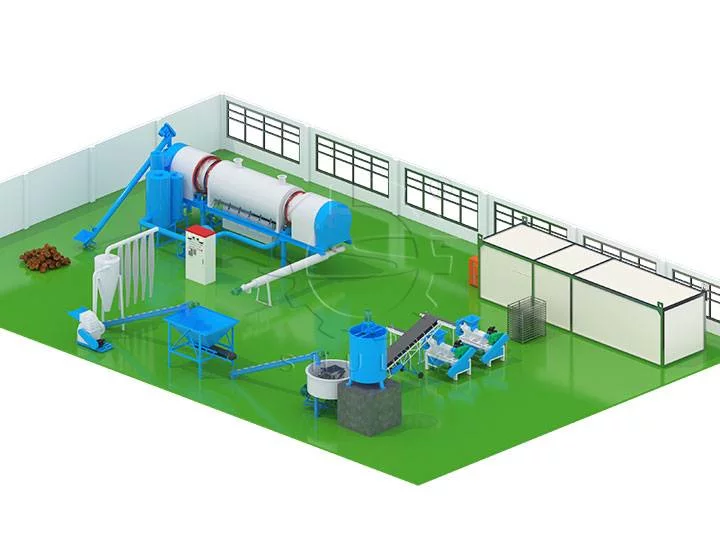

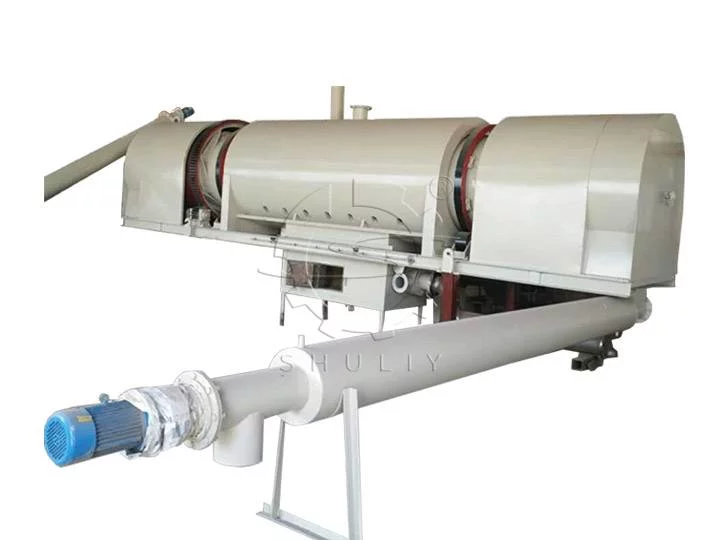

The Main Structure of the Continuous Carbonizing Machine

Continuous carbonization furnace for wood charcoal mainly includes a screw charging system, flat feeding, main machine (rotary drum), condensation discharging system, fire head, combustion pool, purification equipment, and power distribution cabinet, etc.

How Does the Continuous Carbonizing Machine Work?

Loading and Preheating

The process begins by loading biomass materials such as wood chips, nut shells, or agricultural residues into the Continuous Carbonizing Machine’s feeding system. The machine’s main chamber is preheated to the desired temperature, typically between 280°C and 330°C, depending on the type of material being processed.

Initial Combustion

To initiate the carbonization process, a controlled ignition is performed using a fuel source such as liquid petroleum gas (LPG). The LPG is used to create a controlled ignition source that starts the initial combustion in the main chamber.

Carbonization

Once the initial combustion is established, the biomass materials start to undergo carbonization. This process involves the breakdown of organic compounds within the biomass due to the absence of oxygen and high temperatures. As a result, volatile components are driven off as gases, leaving behind solid carbon-rich residues.

Continuous Carbonization Process

The key feature of the Continuous Carbonizing Machine is its ability to maintain a continuous process. As the carbonization proceeds, new biomass materials are continuously fed into the chamber, while the already carbonized materials move along the chamber.

Gas Generation and Utilization

During the carbonization process, gases are produced as byproducts. These gases, which can include combustible components like methane and hydrogen, are extracted from the chamber. In this continuous carbonization system, these gases can be collected and utilized as a potential energy source.

Cooling and Collection

The carbonization process typically takes around 20 minutes for a complete cycle. Once the carbonization is complete, the carbonized residues are moved along the chamber to a cooling section. Here, the residues are cooled using water to ensure safe handling and storage.

Application of Biomass Carbonization Machine

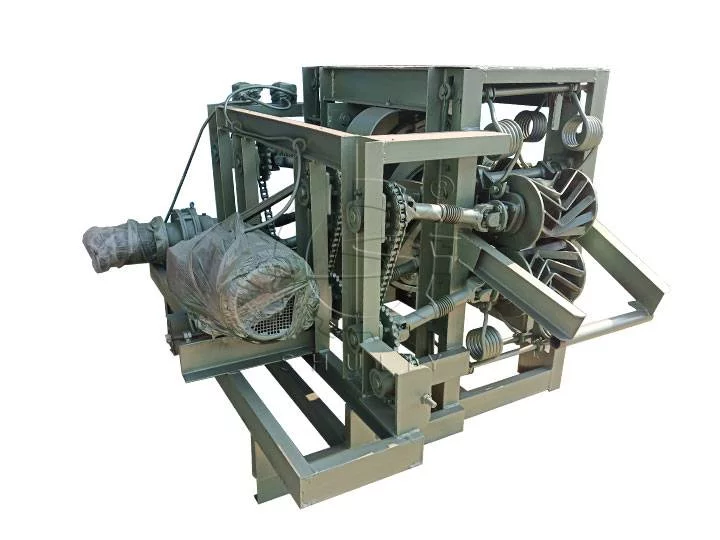

- The biomass carbonization machine is characterized by high output and wide application. This machine can be paired with a wood crusher machine, biomass briquette machine, charcoal dryer, and charcoal packing machine to form a charcoal briquettes production line to make high quality charcoal briquettes.

- Agriculture: The resulting biochar can be used as a soil amendment to improve soil fertility, water retention, and nutrient absorption.

- Environmental Remediation: Biochar can be used to capture and immobilize contaminants in soil and water.

- Renewable Energy: Biomass conversion into charcoal can serve as a renewable energy source for heating and power generation.

What Countries Have Shuliy Carbonization Furnace Exported To?

So far, our continuous carbonization furnace has been exported to Guinea, South Africa, Nigeria, Morocco, Ghana, Cameroon, Yemen, Egypt, Saudi Arabia, Sudan, Philippines, Thailand, Cambodia, Uganda, and many other countries.

FAQ

How much space does the continuous carbonization furnace need to occupy?

A machine needs about 250-300 square meters of space, and the width should not be less than 10 meters

How many workers are needed to use this machine?

3 workers can operate this machine.

Does the machine produce pollution during the carbonization process?

The continuous carbonization furnace for wood charcoal produces wood tar and wood vinegar liquid with back-firing equipment. The backfiring equipment will burn off the wood tar and wood vinegar liquid and will not cause pollution.

Can the material of the main machine of the continuous carbonizing machine be customized?

Yes, we can customize the stainless steel material according to customer’s requirement.

Can the machine process other non-biomass raw materials?

In addition to biomass raw materials, our continuous charcoal carbonization furnace can also process electronic waste, cans, waste electrical wires, household waste, etc.

Carbonization Furnace for Charcoal Making

Shuliy carbonization furnace is used to convert raw materials such…

Horizontal Charcoal Furnace

Shuliy horizontal charcoal furnace is an ideal choice for charcoal…

What Happens During Carbonization?

Carbonization is a fascinating process that involves the conversion of…

Hoisting Carbonizer Machine

Hoisting carbonizer machine refers to a carbonization furnace that incorporates…

Advantages and Disadvantages of Different Carbonization Furnaces Designs

Carbonization furnaces are used to convert wood into charcoal. There…

How to Choose a Biochar Carbonization Furnace?

Carbonization is a process of converting organic materials into carbon…

How Does Wood Turn to Charcoal?

Wood, a renewable resource, can be transformed into charcoal through…

What is a continuous carbonization furnace?

Are you troubled by piles of sawdust, rice husks, coconut…

Continuous Carbonizing Machine and Drum Dryers Successfully Exported to Brazil

How can charcoal production be made more efficient and environmentally…

How to Choose the Right Coconut Shell Charcoal Making Machine for Your Charcoal Plant

Are you planning to set up a coconut shell charcoal…

Hot Product

Comprehensive Crusher for Crushing Pallet, Wood Material

Comprehensive crusher is a machine capable of crushing…

Wood Shaving Machine for Animal Bedding

Wood shaving machine is a mechanical device designed…

Coconut Shell Charcoal Making Machine for Turning Coconut Husk into Charcoal

We have three different types of coconut shell…

Vertical Log Peeling Machine

Vertical log peeling machine is specifically designed to…

Charcoal Briquettes Dryer for Charcoal Drying

The Shuliy charcoal briquettes dryer is a hot…

Drum Wood Chipper for Making Wood Chips

Drum wood chipper is a specialized equipment used…

Horizontal Band Saw Mill

Horizontal band saw mill is a type of…

Continuous Carbonizing Machine for Rice Husk, Sawdust, Bamboo

Continuous carbonizing machine is a kind of equipment…

Rotary Sawdust Dryer Machine | Sawdust Drying Machine

The rotary drum sawdust dryer machine is a…