How Does the Charcoal Ball Machine for Barbecuing Work?

Have you ever wondered how a pile of loose charcoal powder transforms into the hard, long-burning charcoal briquettes that fly off the shelves? It’s no magic trick—it’s all about the precise and powerful mechanics at work.

Many customers have encountered these production challenges: why are my pressed charcoal briquettes not sturdy enough, suffering high breakage during transport? Why do they burn out quickly, leading to customer complaints? The answers lie hidden within the core technology of the charcoal ball machine.

The core issue

Before understanding how it works, we must grasp a core concept: all the advantages of a high-quality charcoal briquette stem from its extremely high density.

Only through stable and immense external pressure can the air between charcoal powder particles be completely expelled, binding them tightly together. This is the fundamental purpose of the charcoal briquette machine.

Working principle of the charcoal ball machine

Our double-roll pellet press achieves the ultimate in pressure application through a set of precision mechanical coordination. The entire process can be broken down into three key steps:

Step 1: forced pre-compression feeding

Unlike simple hoppers, our machine features a screw-driven compression mechanism at the feed inlet. After you load the mixed wet carbon powder into the hopper, this screw device first performs preliminary compression on the material. It then “feeds” it into the core compression zone at a constant speed and force.

What does this solve?

It prevents the “uneven flow” caused by inconsistent material drop due to gravity, ensuring every batch entering the rollers is uniformly dense. This consistency is the foundation for stable molding.

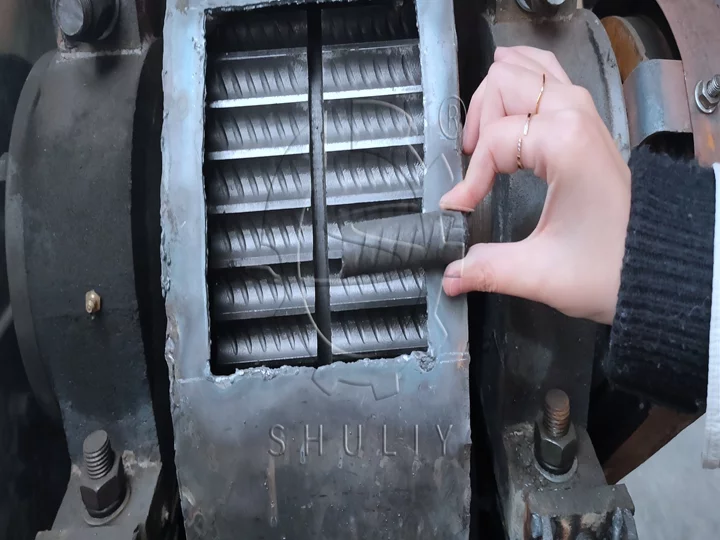

Step 2: high-pressure roller compaction

This is the heart of the entire process. Material is forcibly fed between two massive, synchronously rotating rollers moving in opposite directions. The surfaces of these rollers are densely covered with precision dies in your chosen shape. As the rollers rotate, they create a linear zone of extreme pressure between them.

How much pressure?

This pressure is sufficient to forcibly compress and restructure the carbon powder particles, expelling all internal voids. The particles instantly fuse perfectly with the binder, forming high-density semi-finished carbon pellets.

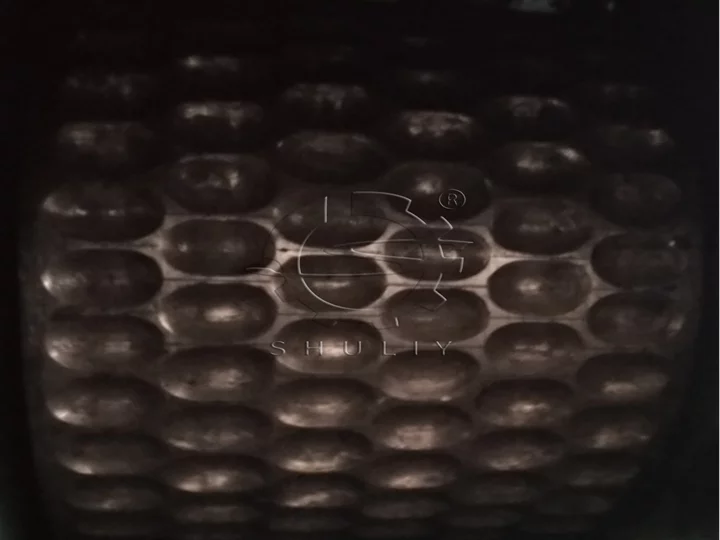

Step 3: automatic forming and demolding

As the press rollers continue rotating, the carbon powder squeezed into the mold is fully formed. Thanks to our precision design of the mold angle and surface finish, the formed carbon pellets automatically detach smoothly from the mold and fall onto the discharge conveyor belt below, ready for the drying stage.

How efficient is it?

The entire process operates continuously, flowing seamlessly from feeding to ball discharge. This achieves truly automated, high-efficiency continuous production.

If you’re interested in our BBQ charcoal ball machine, feel free to contact us for detailed information and a quote.

Understanding the core principle reveals our competitive edge

Understanding the principle enables better choices. Our machines are engineered with a deep grasp of this principle, delivering tangible advantages for you:

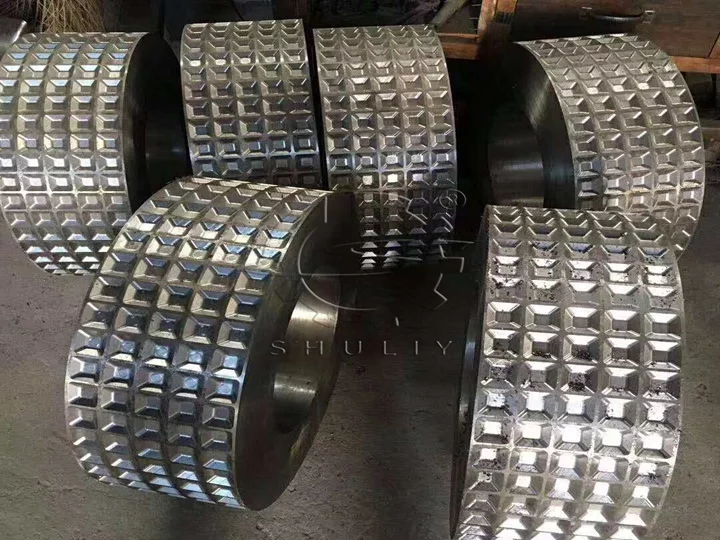

Advantage 1: ultimate hardness

Principal application: the press roll is the core component for applying pressure. We forge press rolls from high-strength alloy steel, delivering hardness and wear resistance far exceeding ordinary cast iron.

Benefits for you:

Provides consistently high pressure without degradation over extended periods. Produces exceptionally hard carbon balls, reducing breakage during transportation. Simultaneously, the press roll boasts a longer service life, saving on long-term maintenance costs.

Advantage 2: customizable precision molds

Principal application: the shape of carbon balls is entirely determined by the mold on the surface of the press rollers.

Benefits for you:

We can customize various molds for you, including pillow-shaped, oval, square, and more, enabling your products to stand out in the market. This effortlessly achieves brand differentiation, freeing you from low-price competition.

Advantage 3: powerful drive system

Principal application: sustained, stable extrusion demands a robust “heart.”

Benefits for you:

We equip each machine model with optimally matched motors and gearboxes. This ensures stable, long-term operation even under heavy loads, safeguarding your production schedule from disruption.

Conclusion

The working principle of a charcoal briquette machine is essentially an art of pressure control.

An exceptional machine not only compresses charcoal powder into shape but also, through its sophisticated design and premium materials, imparts maximum density and commercial value to each briquette.

Want to learn more about transforming your raw materials into high-quality charcoal briquettes? Contact our product experts today to discuss a customized solution.