Charcoal Briquettes Production Line | Briquette Charcoal Plant

Briquette Charcoal Production Line | Charcoal Briquettes Processing line

Charcoal Briquettes Production Line | Briquette Charcoal Plant

Briquette Charcoal Production Line | Charcoal Briquettes Processing line

Features at a Glance

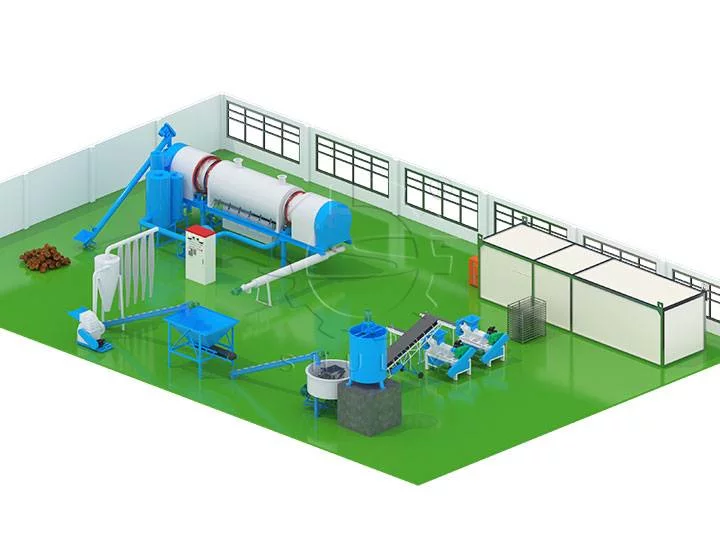

Charcoal briquettes production line is a set of equipment and machinery designed to produce charcoal briquettes from various raw materials, such as wood waste, sawdust, rice husks, coconut shells, and other biomass materials.

The process involves transforming these raw materials into compacted, uniform, and easy-to-use charcoal briquettes, which are commonly used as fuel for cooking, heating, and various industrial applications.

Main Charcoal Machine in Charcoal Briquettes Production Line

Carbonization furnace: in charcoal briquettes production lines, the briquettes go through a carbonization process to enhance their quality. Carbonization removes impurities, resulting in higher-calorific-value charcoal briquettes.

Charcoal crushing machine: the charcoal crusher machine plays a crucial role in the production line, as it is responsible for shredding large biomass charcoal raw materials into smaller particles, making them suitable for further processing.

Charcoal mixer machine: in the mixing stage, the dried biomass materials are thoroughly blended to create a homogenous mixture. This ensures uniform combustion characteristics in the final briquettes.

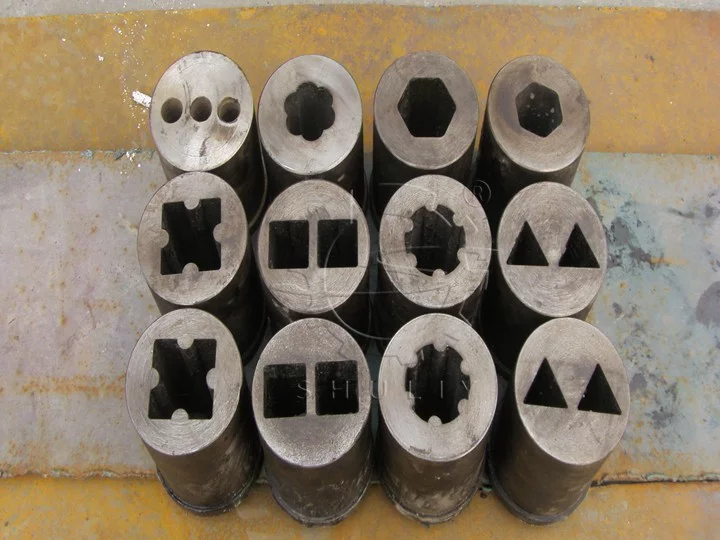

Coal briquette machine: the heart of the charcoal briquettes production line is the charcoal briquette machine, which utilizes mechanical, hydraulic, or screw extrusion presses to compact the mixed materials into the desired briquette shape and size.

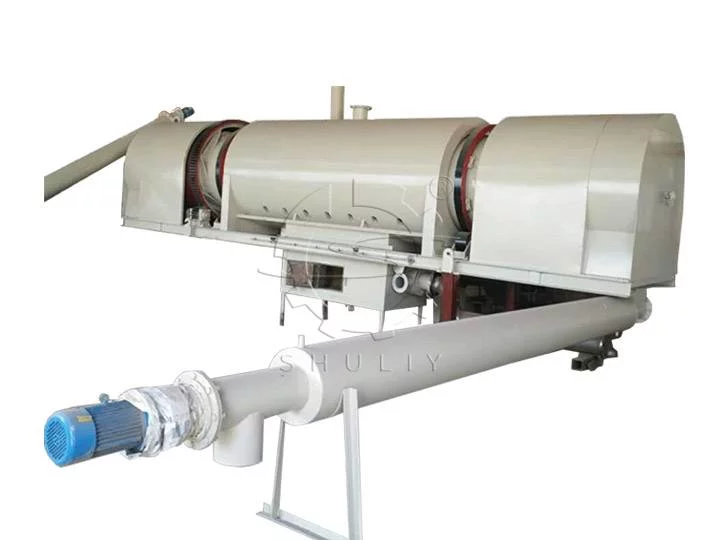

Charcoal briquette drying machine: a charcoal drying machine is a specialized piece of equipment used in the Charcoal briquette production Line or charcoal making process.

Its primary function is to reduce the moisture content of raw materials, such as wood waste, sawdust, or other biomass materials, before they are used to produce charcoal briquettes.

How Is Charcoal Briquette Produced?

Here is the charcoal production method. If you want to start a charcoal production plant, then you need to know it.

Raw material preparation: the first step is to collect and prepare the raw materials. This can involve sourcing, sorting, and shredding the biomass materials to achieve a consistent size and moisture content suitable for the briquette production process.

Carbonization: the second step is carbonization. Formed wood products or biomass products need to be carbonized to become charcoal blocks with high combustion values. This is the main process in the charcoal briquettes production line.

Crushing or pulverizing: next, charcoal materials require crushing or pulverizing to break them down into smaller particles, making it easier for the charcoal briquette process.

Mixing: then the prepared raw materials were thoroughly mixed to create a homogenous blend. This step ensures that the final briquettes have a consistent composition and burning characteristics.

Briquetting: the mixed materials are then fed into a charcoal briquetting machine, which applies pressure and heat to compress them into briquettes of a specific shape and size. The briquette machine may use different technologies, such as mechanical, hydraulic, or screw extrusion presses.

Cooling: the newly formed briquettes might be hot and fragile. They are cooled down to room temperature to enhance their strength and stability.

Packaging and Storing: finally, the charcoal briquettes are ready for packaging. This is the last process in the charcoal briquette production line. We can use a charcoal briquette packing machine to do it. They can be packed in bags or boxes for distribution and storage.

Optional steps: depending on the briquette charcoal production line’s complexity and specific requirements, there may be additional steps such as carbonization or further processing to enhance the charcoal’s quality.

Raw Materials for Making Charcoal Briquettes

- Wood waste: waste materials generated during wood processing or furniture manufacturing, such as wood chips, wood chips, wood blocks, etc.

- Sawdust: fine wood chips and sawdust produced by sawing machines during woodworking.

- Rice husk: the husk of rice, the remaining material after rice processing.

- Coconut husk: the husk of the coconut fruit is usually disposed of as waste, which can be used to make charcoal burning blocks.

- Peanut shell: the shell produced after peanut processing can be used as a raw material for charcoal burning blocks.

- Corncob: the remaining fruit cob after corn processing can be used as a biomass material to make charcoal burning blocks.

- Firewood: firewood for heating and cooking, which can be processed into charcoal burning blocks.

- Herbaceous plant waste: harvested waste from various types of herbaceous plants such as reeds, straw, etc.

- Bamboo waste: bamboo waste, such as bamboo sawdust or bamboo chips, is suitable for making briquettes due to its high calorific value and low moisture content.

What Are the Benefits of Shuliy Charcoal Briquettes Production Line?

Shuliy charcoal briquettes production line offers several benefits that make it a preferred choice for those interested in producing charcoal briquettes:

Good briquetting effect: the charcoal production line can make different types of charcoal briquettes, such as shisha charcoal, honeycomb coal, barbecue charcoal, pini kay, and so on. And the finished products made by this production line are strong, unbreakable, and resistant to burning.

Strict temperature control system: carbonization is the process of decomposing wood into charcoal at high temperatures. Our charcoal briquettes production line allows for strict control of parameters such as temperature, atmosphere, and time to ensure the quality of the charcoal.

Customizable solutions: Shuliy offers customizable solutions tailored to the specific needs and requirements of clients. Whether it’s the capacity, raw material selection, or briquette shape, the production line can be adjusted to meet individual preferences.

Does Charcoal Produce Carbon Monoxide?

Yes, charcoal can produce carbon monoxide (CO) when it is burned or smoldered in an environment with limited oxygen. Carbon monoxide is a colorless, odorless, and tasteless gas that is highly toxic to humans and animals.

When charcoal is burned in an open space with sufficient oxygen, it undergoes combustion and primarily produces carbon dioxide (CO2), which is a less harmful gas.

However, in situations where there is inadequate ventilation, such as in enclosed spaces or poorly ventilated rooms, incomplete combustion can occur, leading to the production of carbon monoxide.

Uses of Charcoal Briquettes

Charcoal briquettes made by charcoal briquettes production lines have various uses and offer numerous advantages in different fields. Some of the common uses of charcoal briquettes include:

Cooking: charcoal briquettes are widely used as a fuel source for outdoor grilling and barbecuing. They provide a consistent and steady heat, making them ideal for cooking meats, vegetables, and other foods.

The even heat distribution and long burning time of charcoal briquettes contribute to delicious and flavorful grilled dishes.

Heating: charcoal briquettes can be used as a source of heat for warming spaces in outdoor settings, such as during camping trips or outdoor events.

They are also used in traditional clay or metal stoves in some regions for indoor heating during colder months.

Industrial applications: charcoal briquettes find applications in various industries. They are used in metal smelting, where they serve as a reducing agent to convert metal ores into pure metal.

Additionally, charcoal briquettes are utilized in some chemical processes and as a heat source in certain industrial furnaces.

Shuliy Charcoal Briquettes Production Line Successfully Sold to Ghana

A client from Ghana possesses abundant coal resources. After thoroughly understanding the characteristics of the raw materials and local market demands, we customized a fully automated briquetting production line with a capacity of 5 tons per hour for him.

The line includes a hammer crusher, a twin-shaft roller mixer, a high-performance briquetting press, and a continuous carbonization furnace.

With high-quality, standardized briquette products, the client quickly established a strong foothold in the local market and became a leading supplier of premium fuel in the region.

Frequently Asked Questions

Do I have to purchase the entire production line?

If you already have some equipment, we can also provide flexible custom solutions.

I have no technical experience. Do you provide installation and training?

Yes, we provide comprehensive technical support, including:

Online guidance: detailed installation videos and 24/7 online engineer support.

On-site service: engineers can be dispatched for on-site installation, debugging, and employee training.

Do I need to find the adhesive formula myself?

As part of our service, our engineers will provide you with a proven adhesive base formulation tailored to your raw materials and guide you through the adjustment process.

Contact Us to Start Your Project!

Our team of experts is ready to provide you with professional consulting services at any time.

Please inform us of your raw material type, desired output, and project location. We will provide you with a free customized solution tailored to your exact needs, including a detailed equipment list and a return on investment analysis.

Charcoal Briquette Machine for Bio Coal Briquettes Making

Charcoal briquette machine, also known as a charcoal briquetting machine,…

Biomass Charcoal Briquettes Machine for Sale in Kenya

In the heart of East Africa lies the beautiful country…

Charcoal Briquette Extruder Machine Exported to Guatemala

In June 2021, Shuliy Charcoal & Wood Machinery proudly dispatched…

How to Make Charcoal Briquettes Burn Longer?

Charcoal briquettes are a popular choice for grilling and cooking…

Shuliy Charcoal Briquettes Machine for Sale in Philippines

In the picturesque archipelago of the Philippines, where the lush…

4 Different Kinds of Charcoal Briquette Press for Sale

If you're looking for the best charcoal briquette making machines…

Where to Buy Wood Charcoal Briquette Machine?

When it comes to procuring a high-quality wood charcoal briquette…

Shuliy Charcoal Briquettes Machine for Sale in the Philippines

In the heart of the Philippine archipelago, a story of…

Charcoal Briquette Machine in South Africa

In the vibrant landscape of South Africa, the demand for…

Hot Product

Drum Wood Chipper for Making Wood Chips

Drum wood chipper is a specialized equipment used…

Disc Wood Chipper for Log Chips Production

Disc wood chipper is a type of machine…

Coconut Shell Charcoal Making Machine for Turning Coconut Husk into Charcoal

We have three different types of coconut shell…

Continuous Carbonizing Machine for Rice Husk, Sawdust, Bamboo

Continuous carbonizing machine is a kind of equipment…

Disc Saw for Wood Cutting

Shuliy's disc saw machine can handle many types…

Charcoal Briquettes Dryer for Charcoal Drying

The Shuliy charcoal briquettes dryer is a hot…

Wood Block Machine | Block Pallet Machine

Wood block machine is a machine that turns…

Wood Crusher Machine for Biomass Waste

Wood crusher machine is a mechanical device used…

Comprehensive Crusher for Crushing Pallet, Wood Material

Comprehensive crusher is a machine capable of crushing…