Sawdust Briquette Machine for Making Pini Kay Briquettes

Biomass Briquette Machine | Sawdust Briquette Press

Sawdust Briquette Machine for Making Pini Kay Briquettes

Biomass Briquette Machine | Sawdust Briquette Press

Features at a Glance

The sawdust briquette machine is a type of equipment used to convert sawdust or other biomass materials into compressed briquettes. In some areas, the sawdust briquette press is also known by another name, the pini kay making machine. These briquettes can be used as a renewable and environmentally friendly fuel source instead of traditional fossil fuels.

Sawdust Briquette Machine for Sale

We have three models of sawdust briquette press for sale. They are SL-15, SL-18 and SL-22.These machines are slightly different in terms of production capacity, motor power, and heating temperature.

Model SL-15 has a production capacity of 160-200 kg/hour. It is equipped with a 15 kW motor and has a heating temperature range of 260-380°C.

The SL-18 has a production capacity of 220-260 kg/hour. It is equipped with an 18 kW motor and the heating temperature range is again 260-380°C.

The SL-22 model has a production capacity of 250-300 kg/h, is equipped with a 22 kW motor, and has a heating temperature range of 260-380°C as well.

The dimensions of each model also vary. the SL-15 has dimensions of 2270x600x1580 mm. the SL-18 has dimensions of 2390x680x1780 mm. and the SL-22 has dimensions of 2390x680x2150 mm.

The design of this sawdust briquette machine makes them suitable for different sizes and production needs, which can efficiently convert wood chips into high-quality sawdust briquettes, contributing to environmental protection and energy utilization.

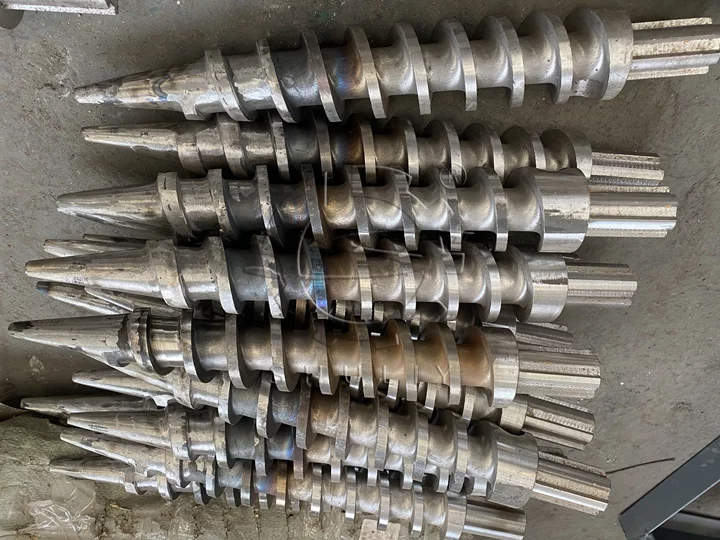

Main Accessories in Sawdust Briquette Press

Heating ring, screw propeller, and mold are the main parts of the sawdust briquettes making machine. The heating ring and screw propeller are also the wearing parts of the machine. The size of the screw can affect the speed and stability of the biomass briquette machine.

The heating ring needs to be replaced after a few months or a year of use. The mold determines the shape of the finished product you want to make. Therefore, if you are shopping for a sawdust briquette press, it is recommended that you buy more of the main accessories.

What Raw Materials Can Be Used to Make Biomass Briquettes?

Common raw materials used to make biomass briquettes include sawdust, grain husks, corn stover, bamboo shavings, bagasse, soybean stalks, rape stalks, sorghum stalks, sunflower stalks, cotton stalks, peanut seedlings, grasses, and shrub branches, etc. If you are not sure whether your material is suitable for making biomass briquette, you can send us a confirmation.

How Does a Sawdust Briquette Machine Work?

- Raw Material Preparation: The first step is to collect and prepare the raw material, which is usually sawdust, but it can also include wood chips, rice husks, straw, or other biomass waste. The raw material needs to be dried to reduce its moisture content, as excess moisture can affect the quality of the briquettes. We can use wood shredders to make wood into the raw materials we want.

- Feeding the Material: The dried and prepared sawdust or biomass is fed into the briquette machine’s hopper. Our machines may have a separate feeding system to ensure a steady and consistent supply of material.

- Compression: Inside the machine, the raw material passes through a die or a mold with specific shapes and sizes for the desired briquette. The die contains small holes or openings that shape the briquettes as the material passes through.

- Mechanical Pressure: As the material enters the die, it experiences high mechanical pressure from the machine’s pressing mechanism. This pressure compacts the sawdust, forcing it to bind together without the need for any additional binders or additives. The lignin is naturally present in the sawdust acts as a binder.

- Forming Briquettes: As the compressed material moves through the die, it takes the shape of the holes, resulting in the formation of briquettes of uniform size and shape.

- Cooling and Collecting: Once the briquettes are formed, they may still be warm from the compression process. They are then allowed to cool down, which helps them retain their shape and strength. The finished briquettes are collected in a container or a bagging system for further use or storage.

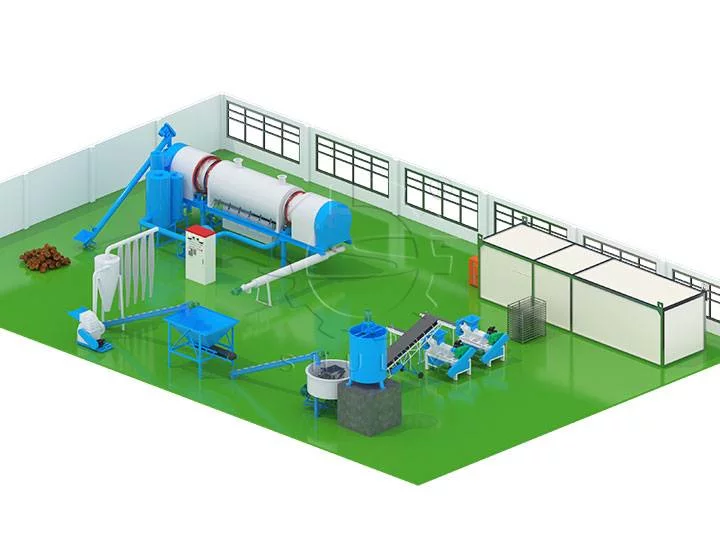

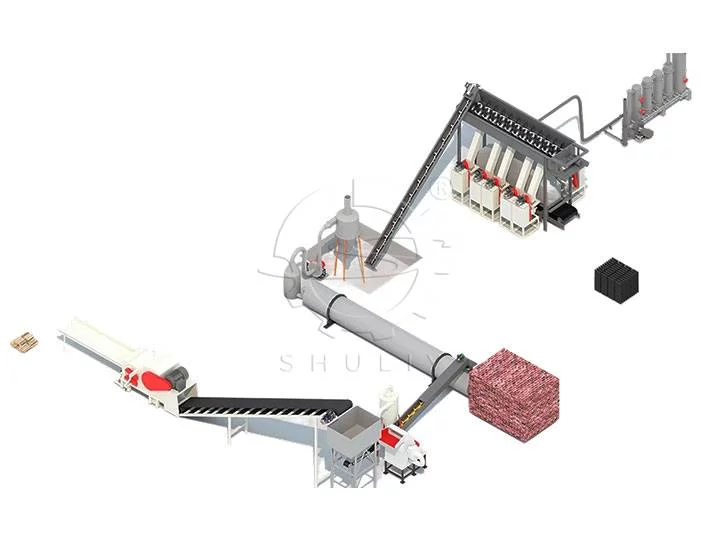

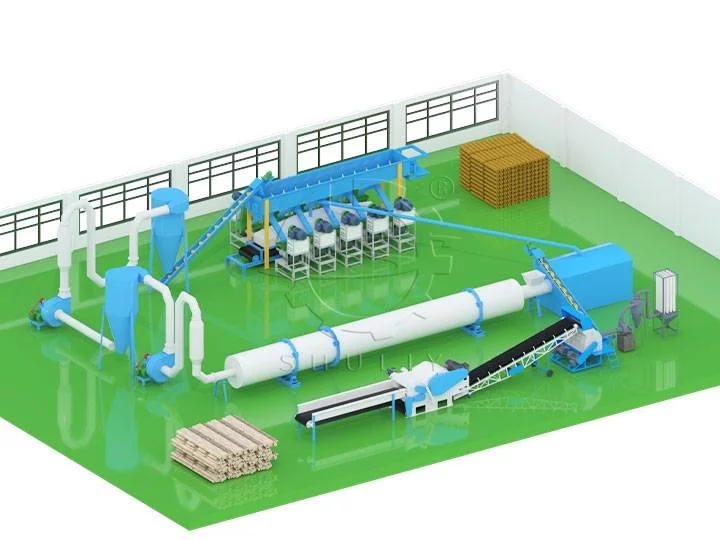

Which Machines Are Needed for a Complete Sawdust Briquettes Production Line?

A complete sawdust briquette production line includes a wood hammer mill, wood chips dryer machine, screw conveyor, sawdust briquette machine, and sawdust briquette packing machine. These machines are a must if you want to get high-quality wood briquette.

What Is the Price of Sawdust Briquette Machine?

The price of the pini kay briquette machine varies greatly according to the output. Generally, sawdust briquette making machines cost between $2,000 and $20,000. The price of a complete sawdust briquette production line is relatively expensive. The price of a small sawdust briquette machine will be cheaper. If you want to get a specific quotation, please contact us and tell us your capacity. Then our sales will contact you quickly and give you a detailed quotation.

The Benefits of Shuliy Biomass Briquette Machine

- No Need for Binders: One of the significant advantages of the Shuliy biomass briquette machine is that it does not require the use of any additional binders or additives during the processing. The machine utilizes high pressure to compress the sawdust, and the natural lignin present in the sawdust acts as a binder, holding the briquettes together.

- Smooth Surface of Briquettes: The briquettes produced by the Shuliy machine have a smooth and uniform surface, thanks to the precise compression process. This ensures a consistent and attractive appearance, making them ideal for various applications.

- Intelligent Control Cabinet: The Shuliy biomass briquette machine is equipped with an intelligent control cabinet that allows users to regulate and monitor the production process easily. This feature enhances operational efficiency and ensures the production of high-quality briquettes consistently.

- High Briquette Density and Long Burning Time: The machine’s advanced compression mechanism results in briquettes with high density, which means they have more energy content. As a result, these briquettes burn for a longer duration, providing efficient and sustained heat for cooking, heating, or other applications.

- Safety Features: The Shuliy biomass briquette machine is designed with safety in mind. It comes equipped with a metal cover that protects the briquetting process, minimizing the risk of accidents or injuries.

Why Is Sawdust Briquette Gaining Popularity?

The main reason for the vast market for sawdust briquette is that it has a wide range of applications in several fields as an environmentally friendly, efficient, and sustainable energy alternative.

- Firstly, with the increasing global emphasis on environmental protection and sustainable development, replacing traditional fuels has become an important issue. Sawdust briquette, as a green fuel made from renewable biomass waste, has low carbon emissions and non-toxicity, which can effectively reduce air pollution and greenhouse gas emissions.

- Secondly, the process of making sawdust briquette does not require the addition of a binder, utilizing the raw material’s lignin as the binder, which reduces production costs and allows the charcoal to burn more cleanly and efficiently.

- In addition, sawdust briquette can be used in a variety of applications, including home heating, industrial heating, kitchen cooking, and electric power generation, meeting the fuel needs of different sectors.

The final product made by the sawdust briquette machine can be used directly as fuel, or it can be put back into the carbonization furnace to make charcoal briquettes.

How to Use A Sawdust Briquette Machine?

Prepare Raw Materials

Gather and prepare the raw materials, which are usually sawdust or other biomass waste materials like wood chips, rice husks, straw, etc. Ensure that the raw materials are dry and free from impurities, as excess moisture can affect the briquette quality.

Load the Hopper

Open the feeding hopper of the sawdust briquette machine and add the prepared raw materials into it. Some machines may have separate feeding systems for a consistent supply of material.

Adjust Compression Pressure

Depending on the type and design of the machine, you might need to adjust the compression pressure. This can be done through the machine’s control panel or settings.

Start the Machine

Switch on the sawdust pini kay briquette machine and start the compression process. The machine will use mechanical pressure to compress the raw materials, forming them into briquettes.

Collect the Briquettes

As the briquettes are formed, they will come out from the other end of the machine. Collect the finished briquettes in a container or onto a conveyor belt for further handling or packaging.

Do you need a high-quality Sawdust Briquette Machine? If you need it, please feel free to contact us. As a professional biomass briquette machine manufacturer, we will try our best to help you.

Sawdust Briquettes Production Line for Sale

Sawdust briquettes production line is a set of sawdust briquettes…

Sawdust Press Machine Shipped to Cambodia

In September 2021, a high-quality sawdust press machine embarked on…

Sawdust Briquette Machine for Sale in South Africa

In November 2021, a high-quality sawdust briquette machine embarked on…

Hot Product

Wood Shaving Machine for Animal Bedding

Wood shaving machine is a mechanical device designed…

Rotary Sawdust Dryer Machine | Sawdust Drying Machine

The rotary drum sawdust dryer machine is a…

Coconut Shell Charcoal Making Machine for Turning Coconut Husk into Charcoal

We have three different types of coconut shell…

Vertical Bandsaw Mill for Wood Processing Plant

Vertical bandsaw mill is a type of sawmill…

BBQ Charcoal Packing Machine | Quantitative Packing Machine

BBQ charcoal packing machines are specialized equipment designed…

Double Roller Wood Debarker Machine for Wood Processing

Double roller wood debarker machine can handle various…

Horizontal Charcoal Furnace

Discover our efficient, eco-friendly horizontal charcoal furnace. Perfect…

BBQ Charcoal Briquettes Machine

By changing molds, our BBQ charcoal briquettes machine…

Wood Crusher Machine for Biomass Waste

Wood crusher machine is a mechanical device used…